Formed Mash Line

_______________

Whether formed mash products are your primary product or a by-product of your other production lines, Kiremko machines deliver the highest standard in efficiency, hygiene and durability.

-

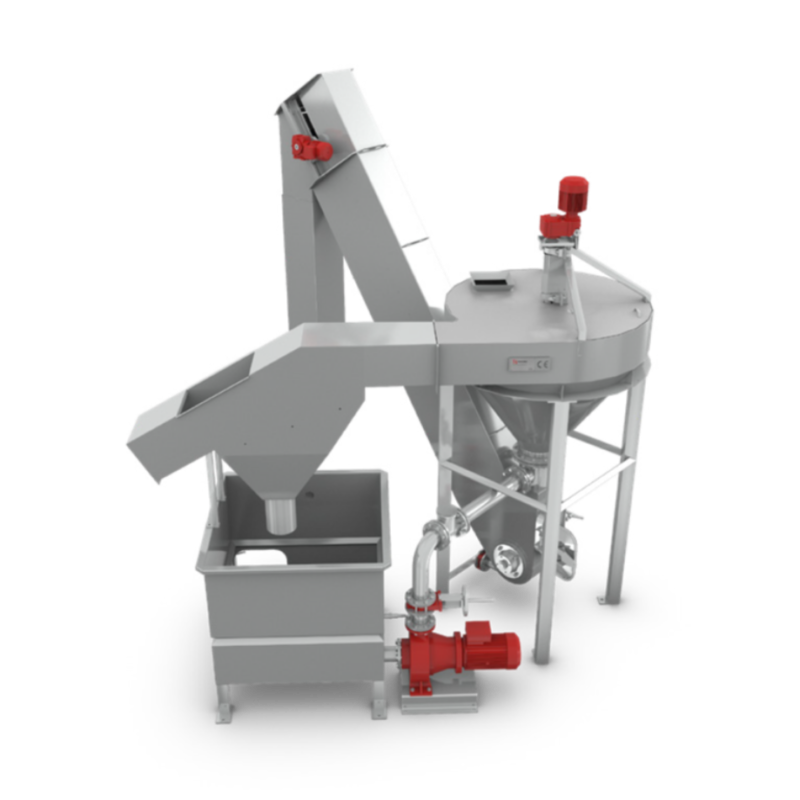

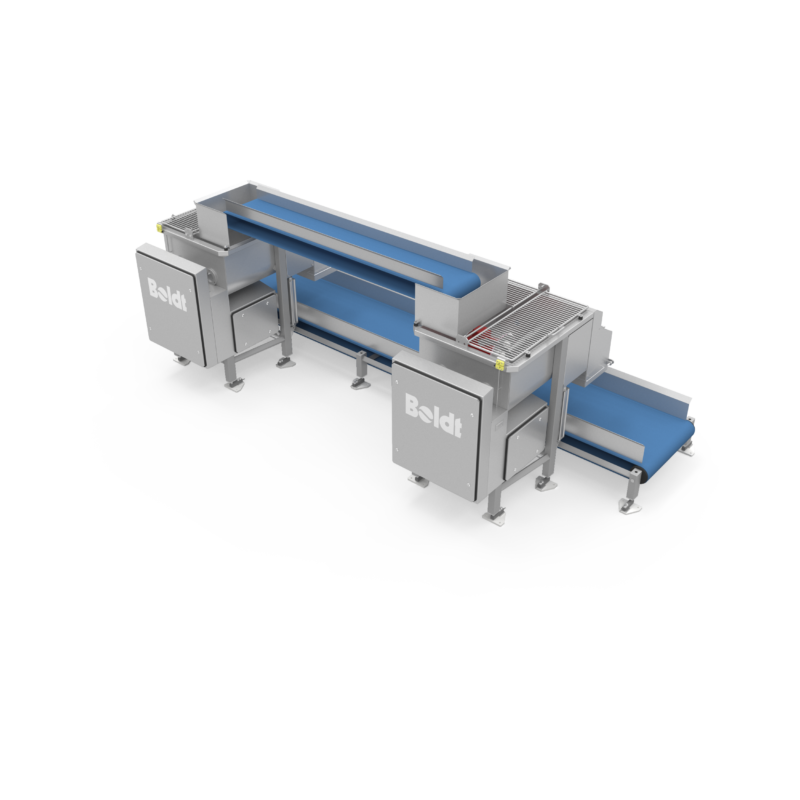

Pre-cleaning

-

Peeling

-

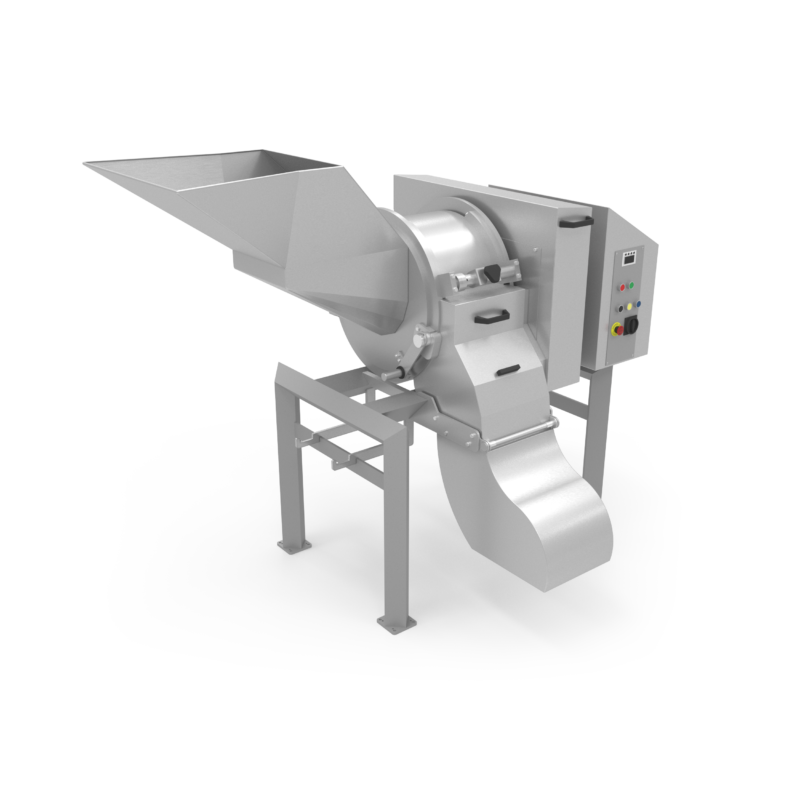

Cutting and Sizing

-

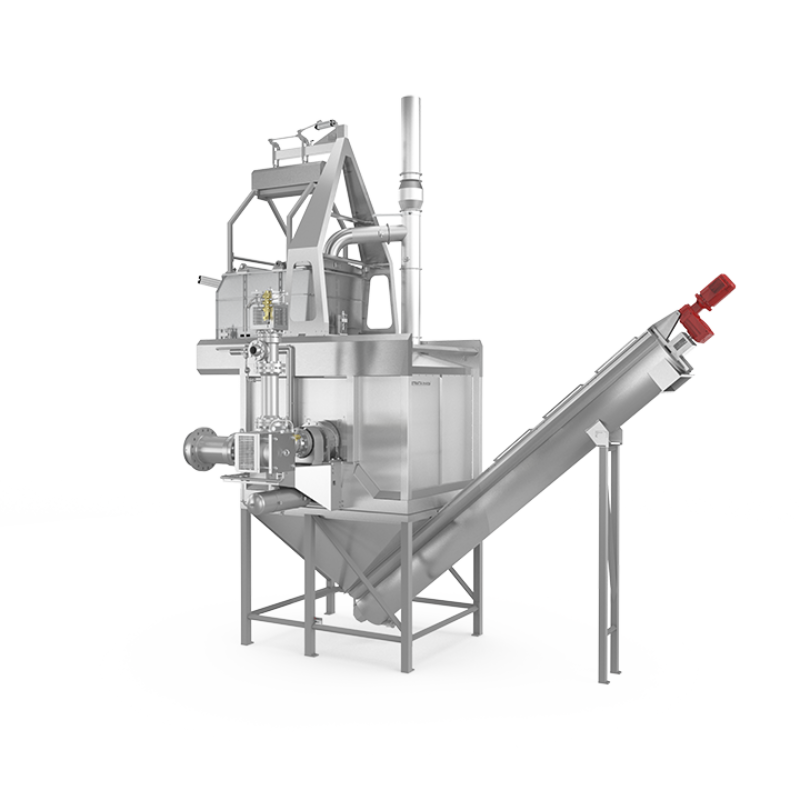

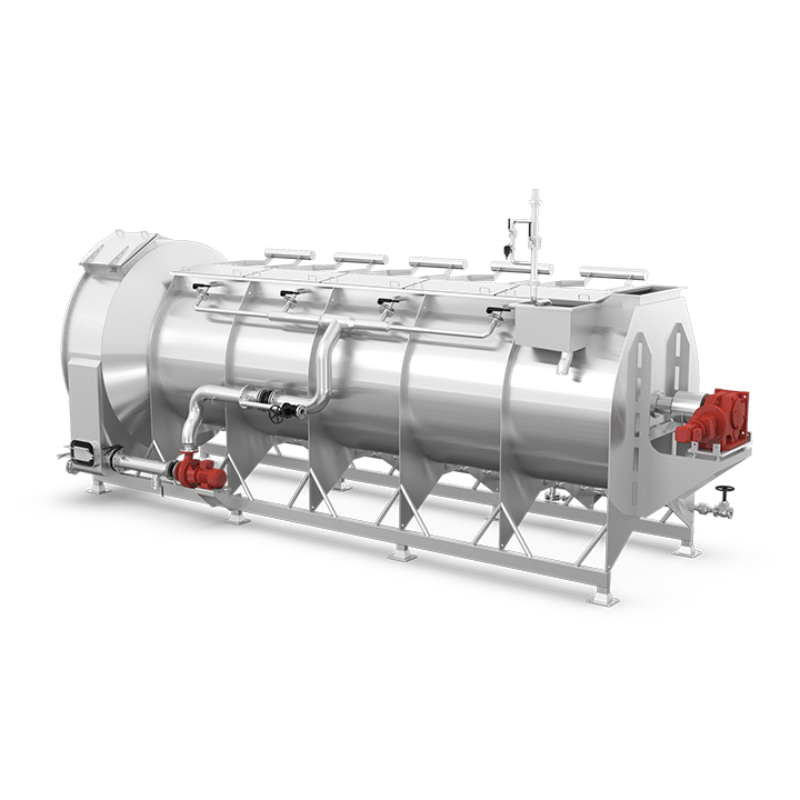

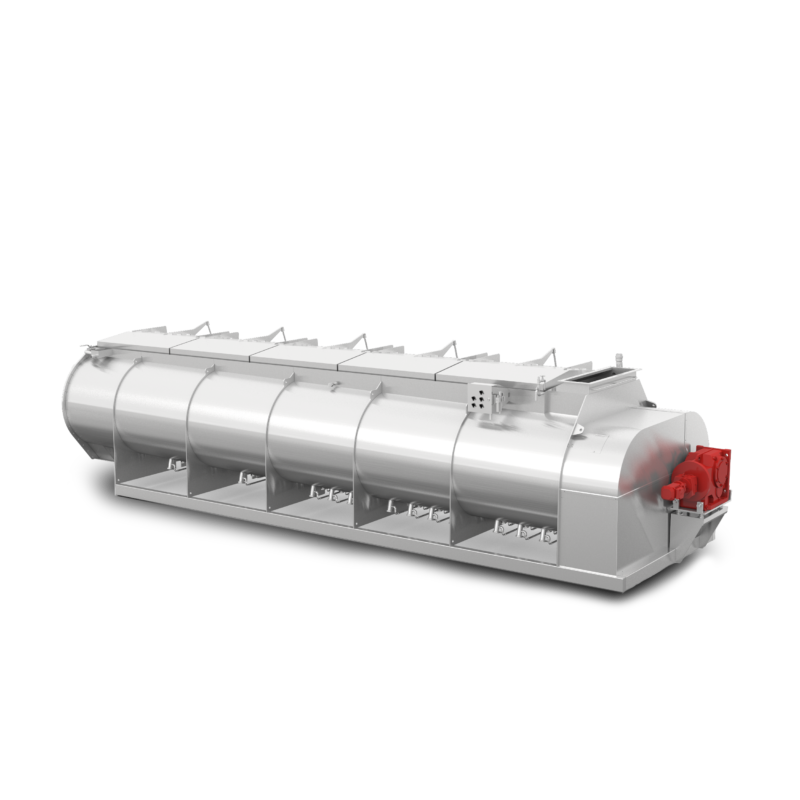

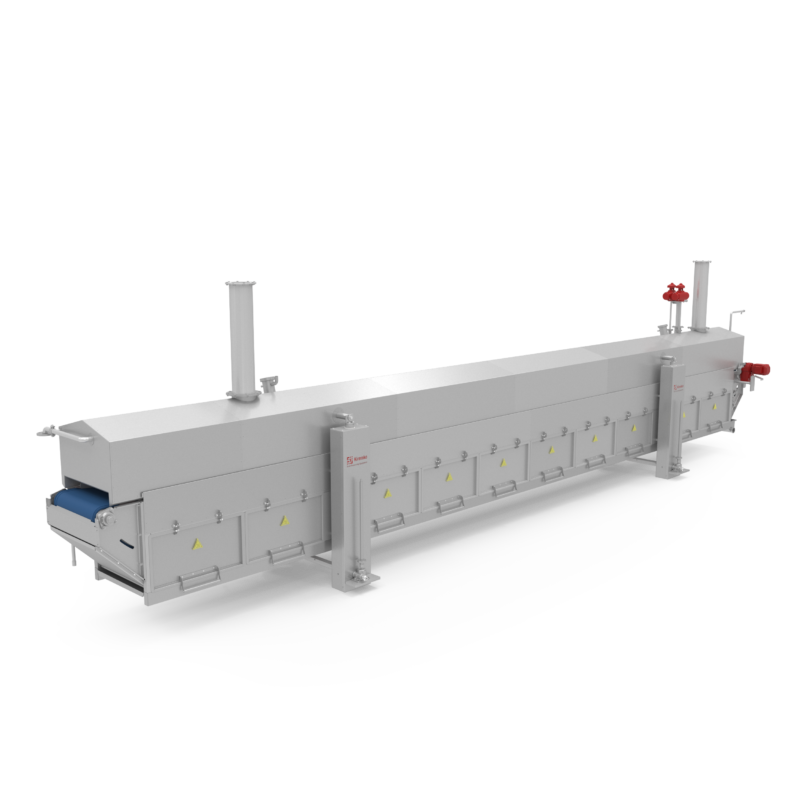

Blanching

-

Cooling

-

Cooking

-

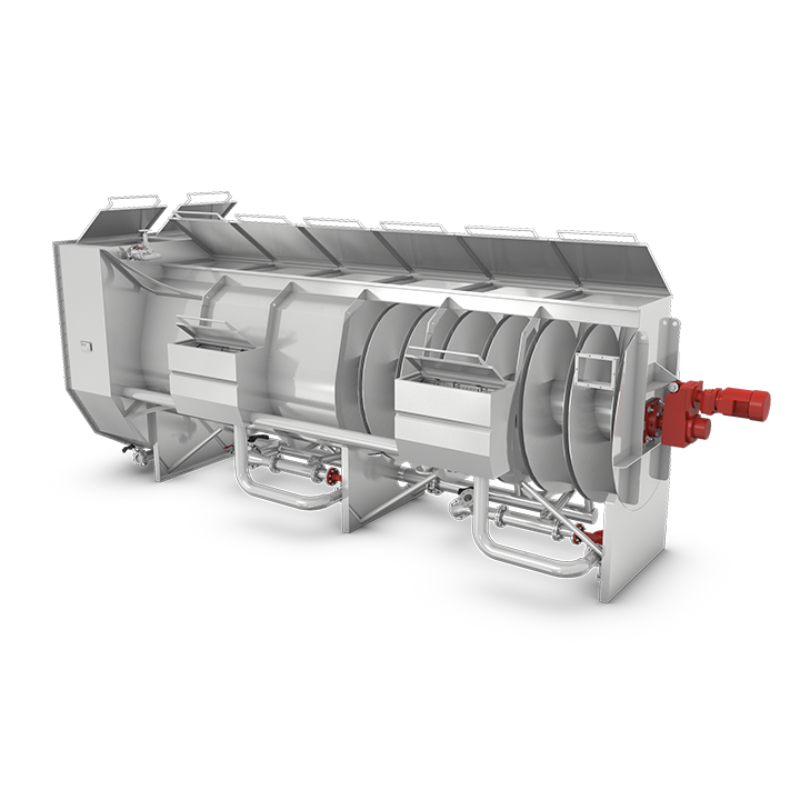

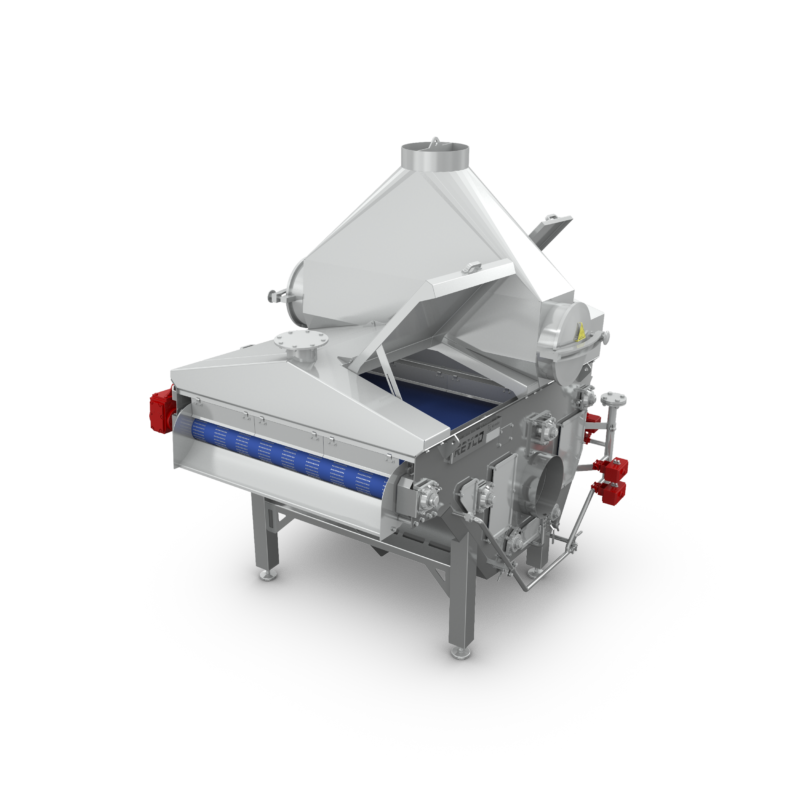

Mashing

-

Mixing

-

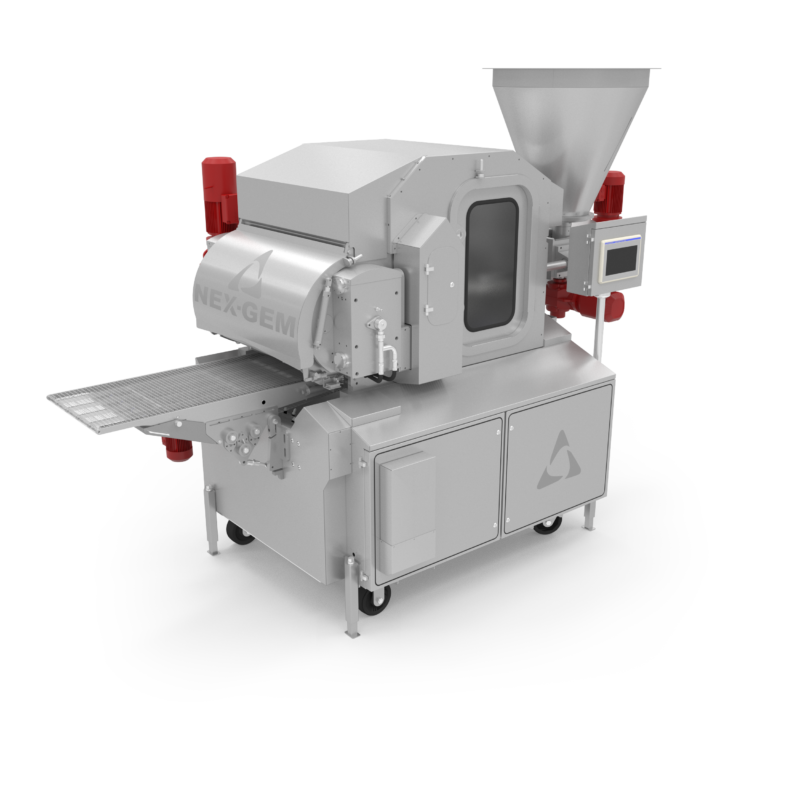

Forming

-

Frying

Learn more about the Formed Mash Line

Download brochure

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment

McCrum grows trust

In July 2020 McCrum (Belfast, Maine, US) started up their new Coated French Fries production line with a capacity of 8 tons finished product an hour. The company, founded in 1886, has a rich history of adding value to the potato, from field to plate.

Go to case