Potato Chip Line

_______________

Offering perfect, well-balanced potato chips to the consumer is an art-form. Kiremko is the ideal partner for this, with machines that can develop a wide variety of potato chips at a constant quality. The well-balanced engineering and user-friendliness of our machines will enable you to deliver top products every day.

-

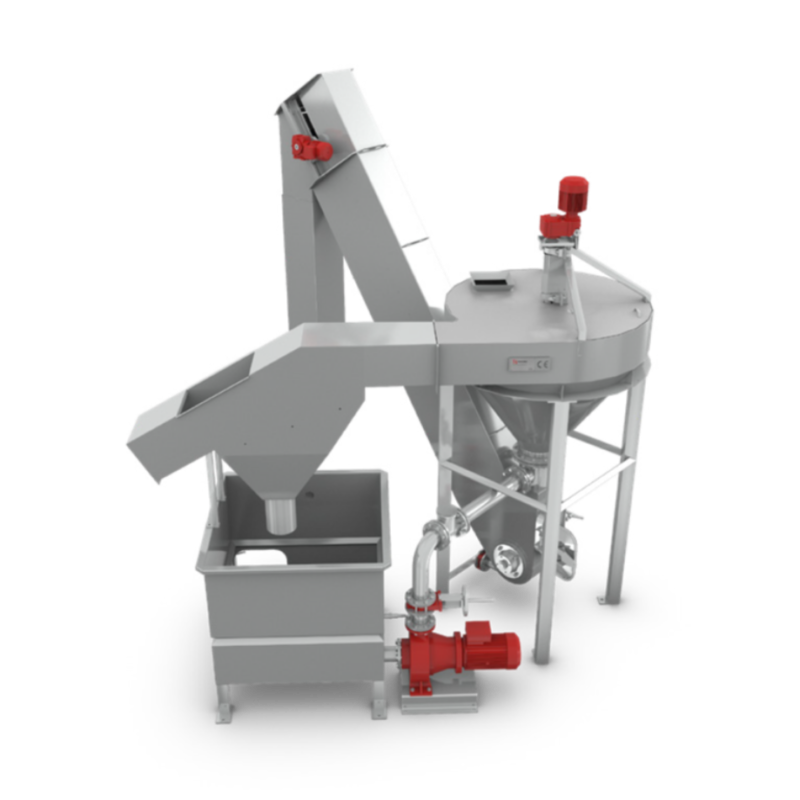

Pre-cleaning

-

Peeling

-

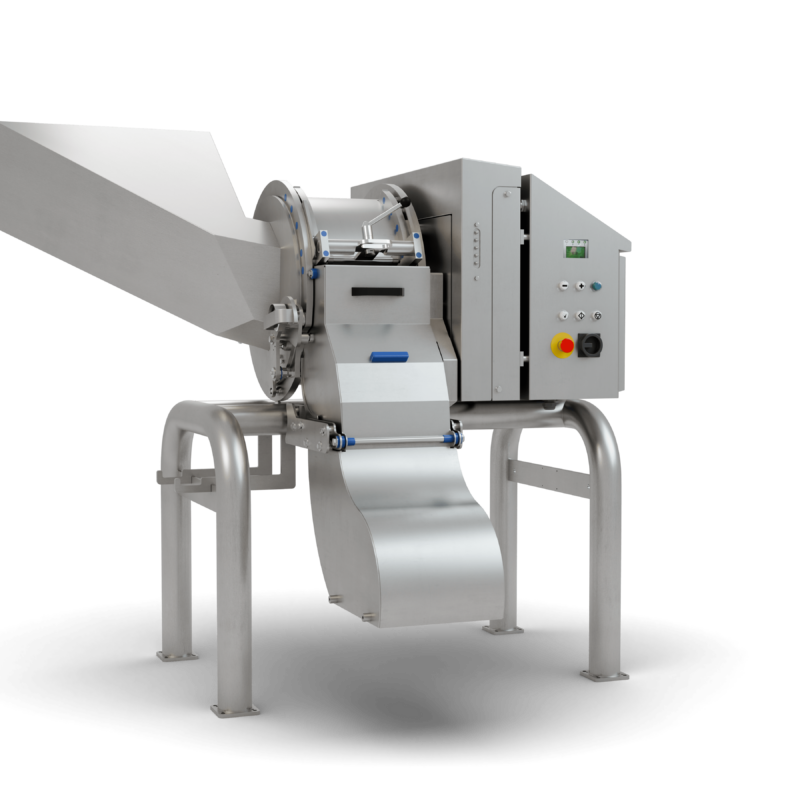

Cutting

-

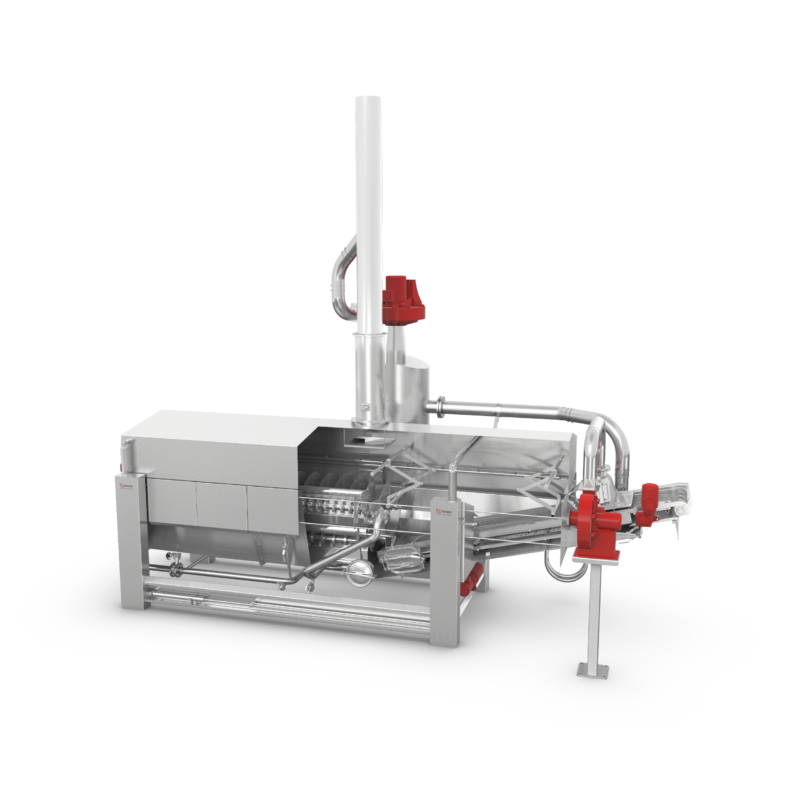

Blanching

-

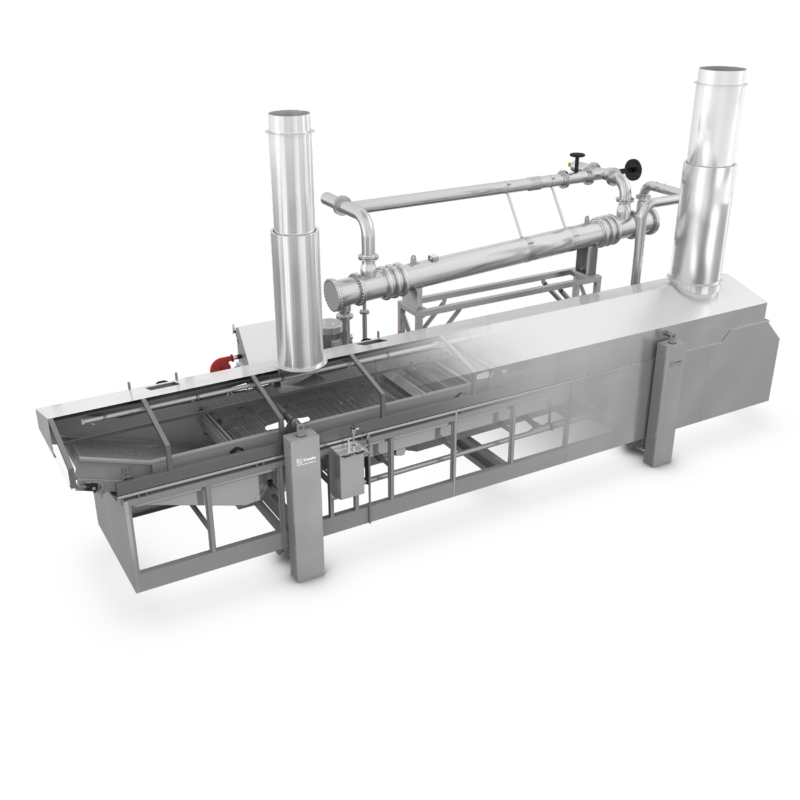

Frying

-

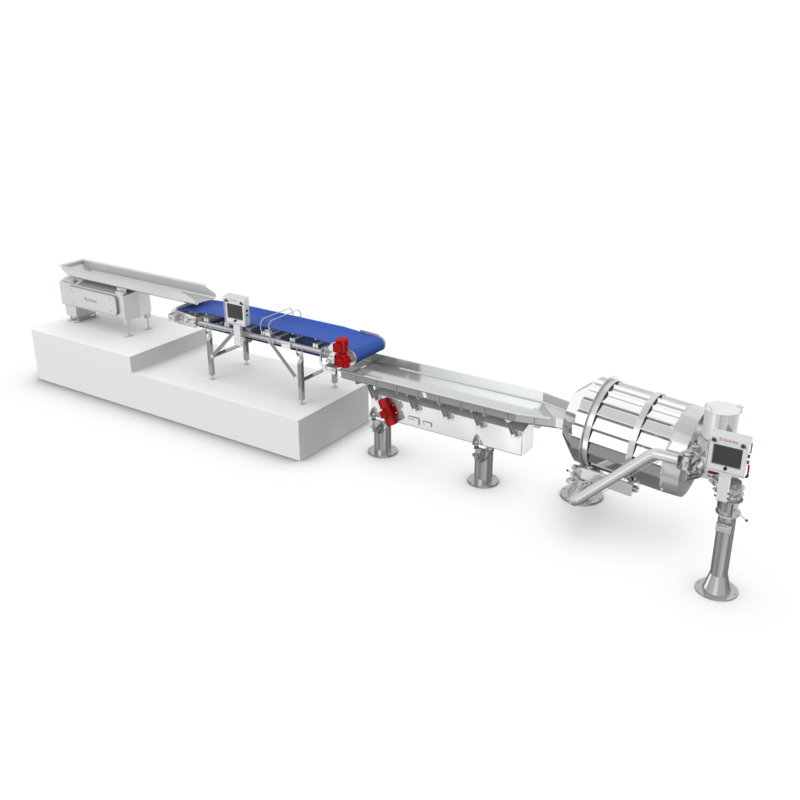

Flavouring

Learn more about the Potato Chip Line

Download brochure

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment

At Kiremko, we believe that the future of our industry lies in the hands of skilled and motivated young professionals. That’s why we proudly support the Skillspaspoort—a powerful tool that helps make talents visible and guides career development. In collaboration with FME, we recently took part in a national campaign to promote this initiative, featuring interviews with our own young team members. Discover how the Skillspaspoort is helping them grow and how Kiremko continues to invest in technical education for the next generation.

McCrum grows trust

In July 2020 McCrum (Belfast, Maine, US) started up their new Coated French Fries production line with a capacity of 8 tons finished product an hour. The company, founded in 1886, has a rich history of adding value to the potato, from field to plate.

Go to case