"The people of Kiremko and Idaho Steel take their projects personally"

McCrum

- Keywords

- McCrum

- Capacity of 8 tons

- Success of partnership

- Process line

- Cooperation

McCrum grows trust

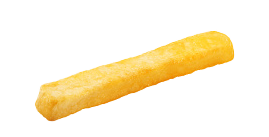

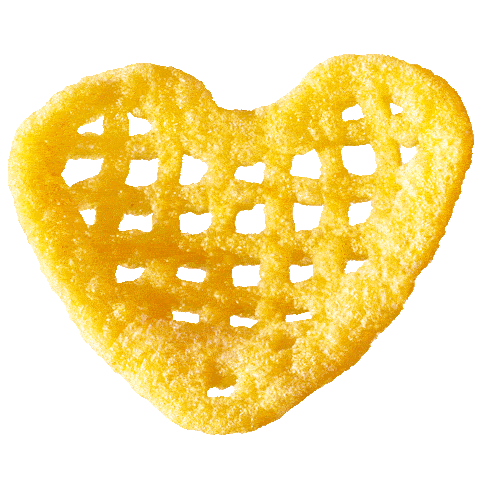

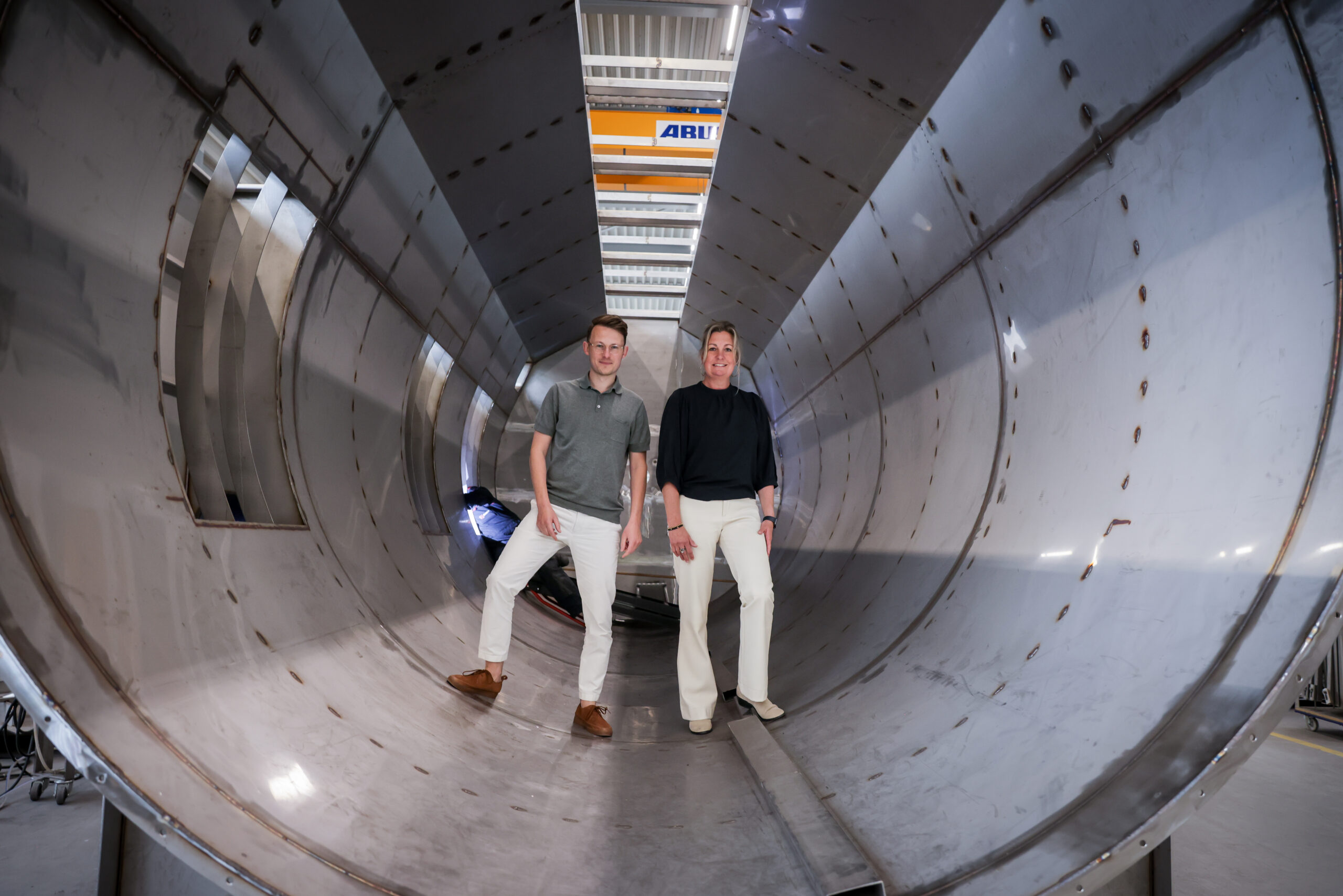

In July 2020 McCrum (Belfast, Maine, US) started up their new Coated French Fries production line with a capacity of 8 tons finished product an hour. The company, founded in 1886, has a rich history of adding value to the potato, from field to plate.

”This project with Kiremko and Idaho Steel was a big project for our family. Trust with Kiremko and Idaho Steel has grown from day one. Our family considers them as partners now. Although they are both global operating companies, the people of Kiremko and Idaho Steel take their projects personally. And that creates the right setting for success.”

On time, within budget.

It’s our showpiece.

Jay McCrum, director of McCrum, looks back on a process, from first contact to final supply. “Kiremko and Idaho Steel know how it works. They created an atmosphere where we could be ourselves, to meet the future. Our success is their goal. Both Kiremko and Idaho Steel add up to the highest standards. As a customer you feel you are a part of their partnership, offering the best of both worlds. For us it was practical to have Idaho Steel as our supplier, because of currency, time zones, local supply, and spares. But we went through the whole sales process with Kiremko. It took them not more than a few seconds to find a solution in our favor. So now we started our Kiremko/Idaho Steel production line for 8 tons of French fries an hour. Within planning, within budget. Next week we are inviting two of our key customers to come over and have a look at our newest showpiece.”

MCCRUM

Within planning, within budget

Idaho Steel and Kiremko have been working together since 1996 and the relationship built over the years is based on friendship, trust and a mutual love of the potato. In 2005 Reyco joined the family. Together, the ‘Tri-brand’ has over 50 years of experience in the potato processing industry.

Unending innovation and complete devotion to the success of the customer guarantee that the customer always gets the best equipment, that is not only more powerful and efficient, but also low-maintenance and water and energy efficient, without sacrificing the quality of the end product.

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment