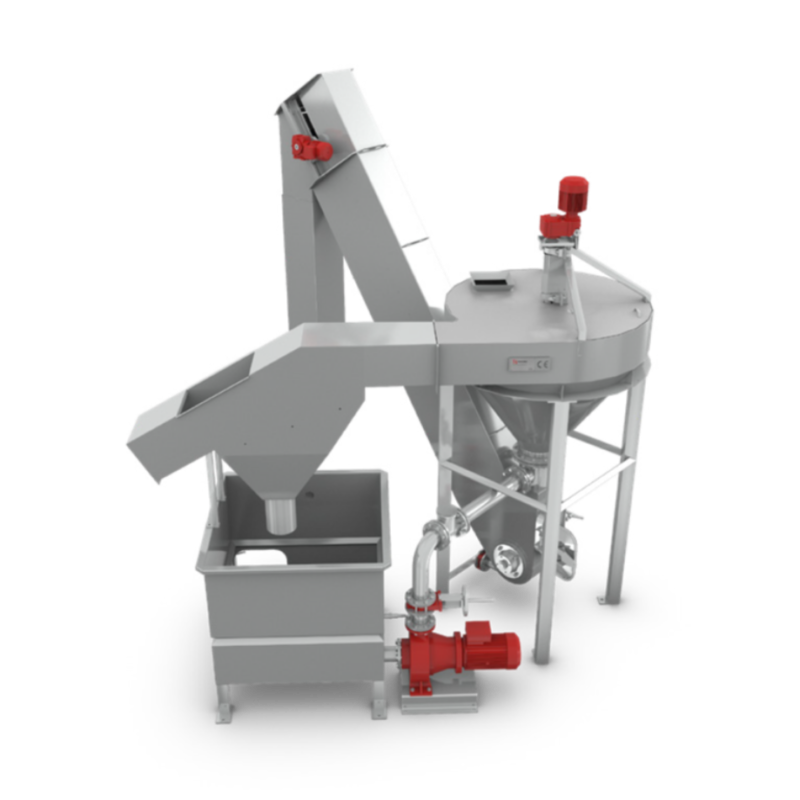

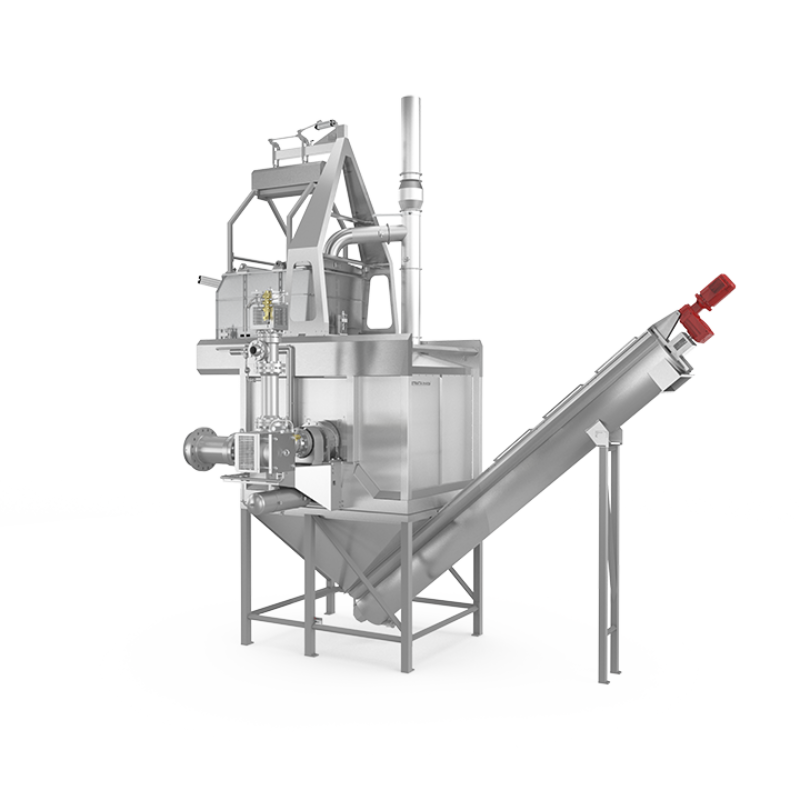

Flake line

_______________

Whether potato flakes are your primary product or whether they are a by-product of your other potato (or other) production lines, our machines will deliver optimum results in efficiency, hygiene and durability.

-

Pre-cleaning

-

Peeling

-

Weighing and dosing

-

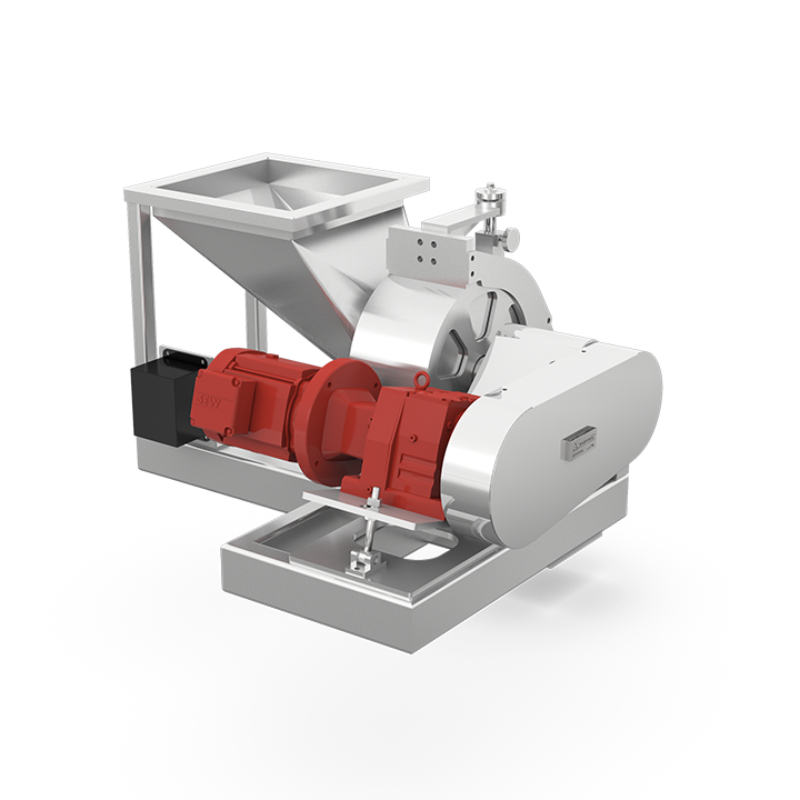

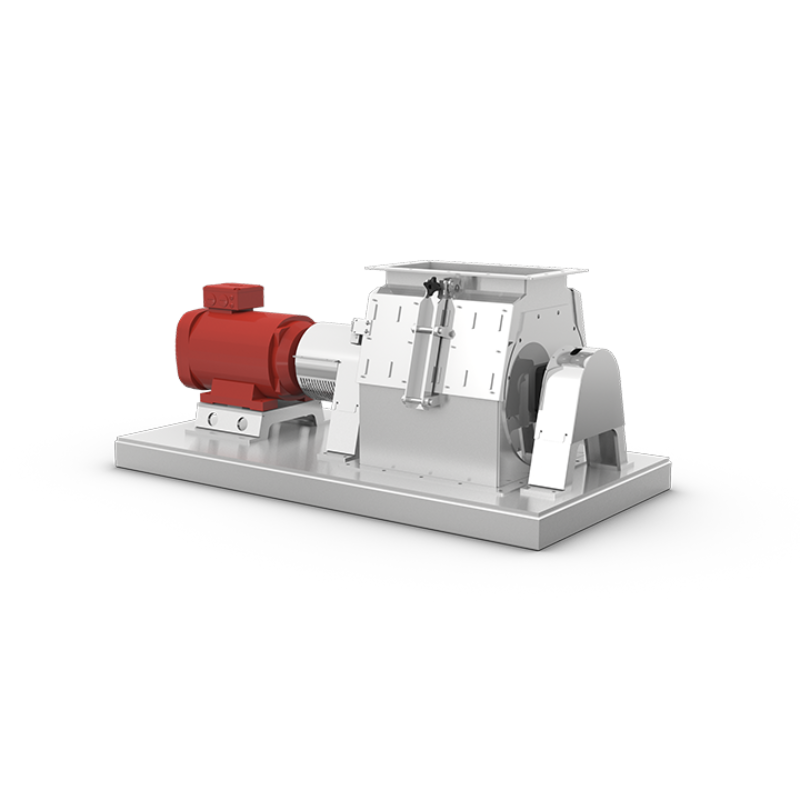

Cutting and Sizing

-

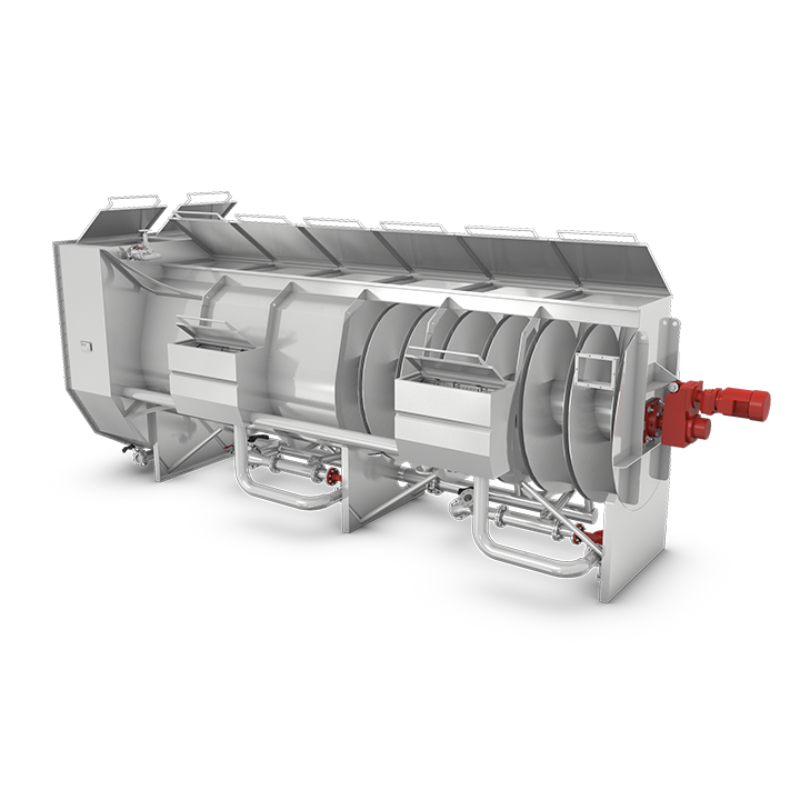

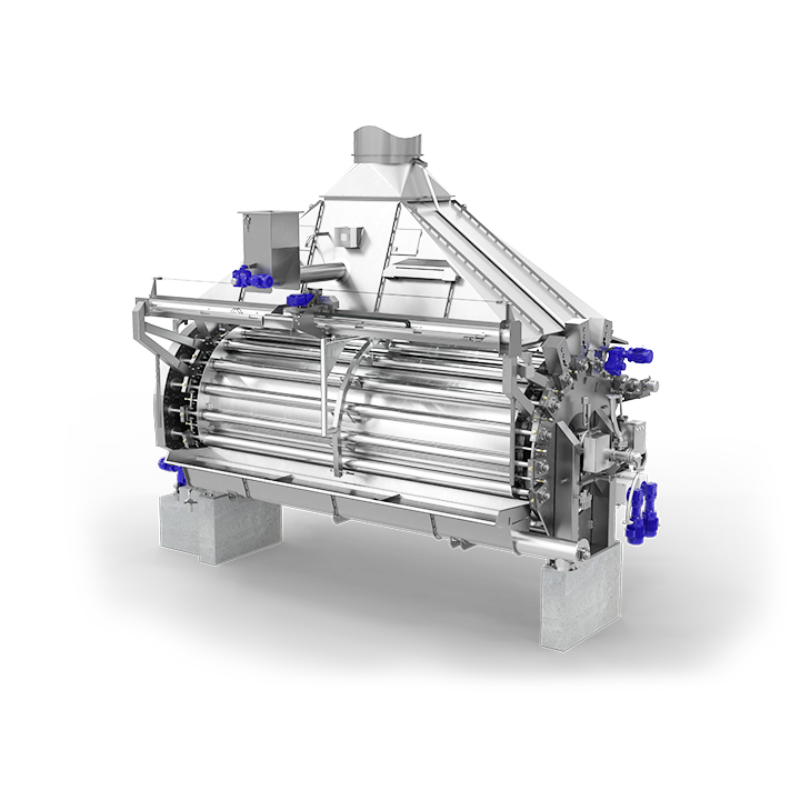

Blanching

-

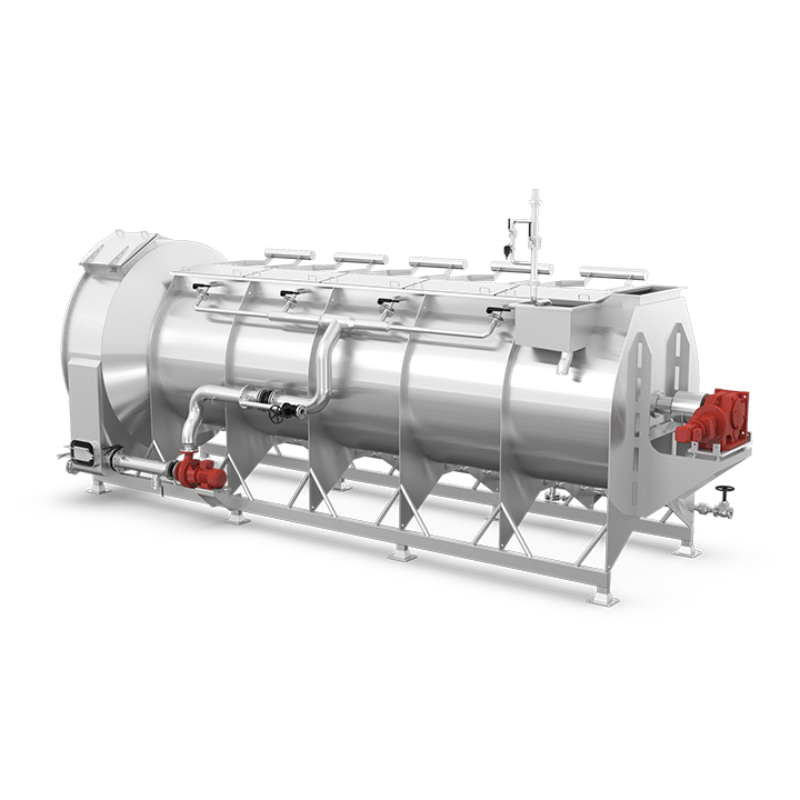

Cooling

-

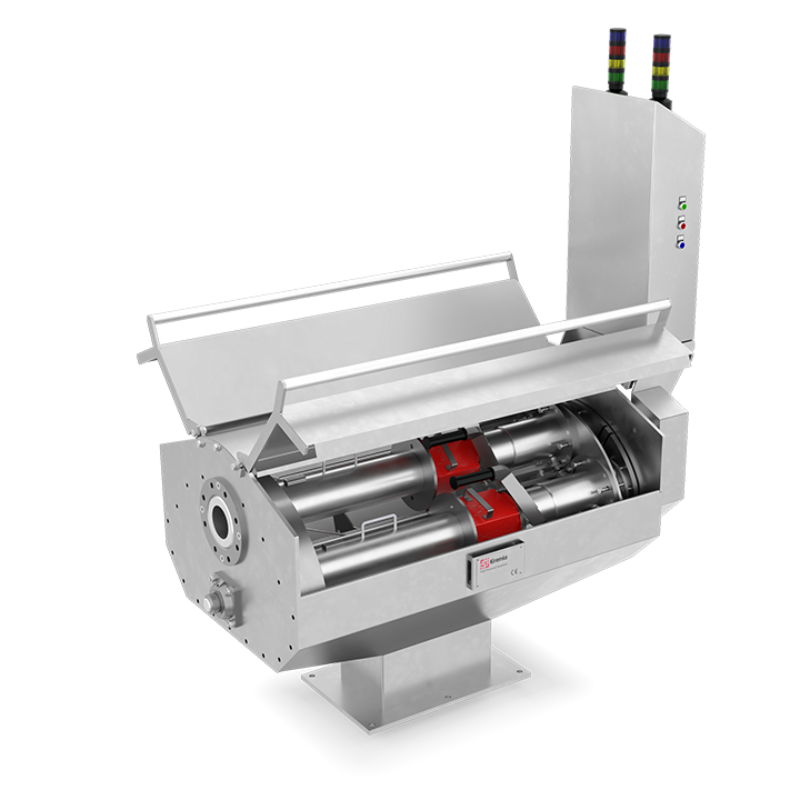

Drying

-

Cutting and Sizing

Learn more about the Flake Line

Download brochure

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment

Discover how HZPC and Kiremko’s global potato processing partnership drives innovation, sustainability, and growth across the potato chain.

Kiremko, Idaho Steel and Reyco have entered a new era of leadership and growth with the appointment of Gerardo Chiaia as President and CEO and Kees van der Drift as CFO. Supported by Investindustrial, the group is uniting its global expertise to strengthen its position as a leader in food processing innovation and integrated solutions.

Reducing food loss and waste in potato processing is central to Kiremko’s mission. Through innovation, sustainability, and AI-driven efficiency, we are shaping a smarter, waste-free future.

McCrum grows trust

In July 2020 McCrum (Belfast, Maine, US) started up their new Coated French Fries production line with a capacity of 8 tons finished product an hour. The company, founded in 1886, has a rich history of adding value to the potato, from field to plate.

Go to case