How to get the best out of your employees – Interview

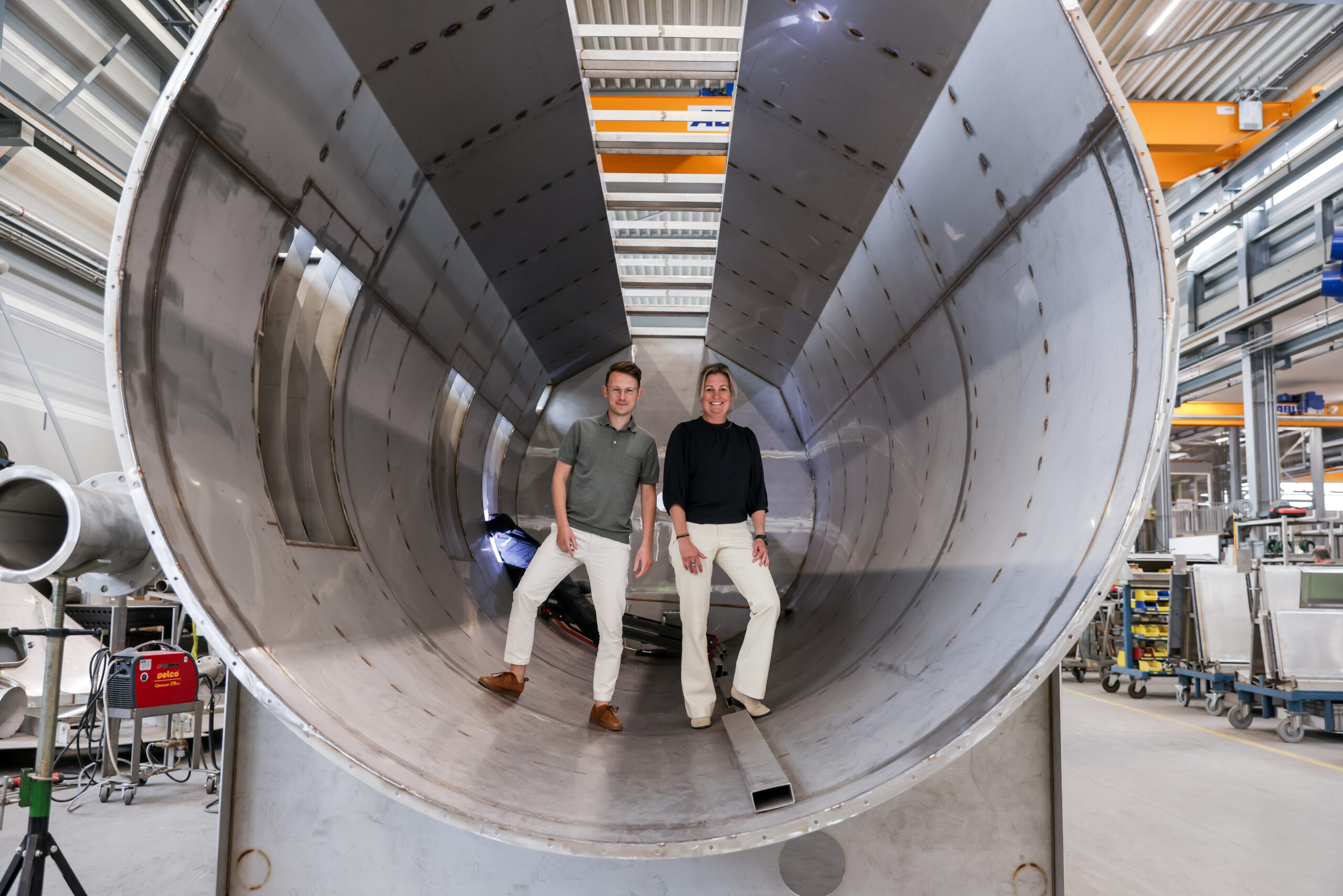

On Kiremko’s website you will read that their goal is clear: getting the best out of every potato. The team of 230 motivated colleagues at the head office in Montfoort forms the basis for this reach. That is why it is important to also get the best out of employees. Nicole Peters, Manager Sustainability and Communication, together with Nick Vreeman, Coordinator Learning & Development on how they approach this.

Interview with Nicole Peters, Manager of Sustainability and Communications

and Nick Vreeman, Coordinator of Learning & Development at Kiremko

Originally published in magazine Ondernamen Lopikerwaard summer 2024

- Keywords

- Interview

- Kiremko employees

- Technical education

- Development and knowledge transfer

Engaging Young People

During a tour of the company we also pass by “the lab”. Here Kiremko simulates a complete production line: from potato to fries. The students are active participants while receiving an explanation about the entire process. But it is not only at Kiremko in Montfoort that young people are tempted to choose technical professions.

Directors’ Commitment to Youth in Technical Education

For example, directors Paul Oosterlaken and Marcel van Huissteden are closely involved with the TechnoHub training locations in Woerden and the MAKE Center in Nieuwegein. Nicole: ‘Their personal mission is to introduce as many young people as possible to technical professions and education. It doesn’t matter where they end up getting a job, as long as they are happy and have been given the opportunity to grow in their profession.’

When new colleagues arrive at Kiremko, they are guided step by step and prepared for their work. Nick: ‘We even have our own Online Academy. This now contains more than sixty e-learning courses, which have been developed for and by colleagues. This way, we instantly capture the knowledge we possess and make it accessible to everyone. Each person is evaluated to determine which e-learning courses are relevant for starting their new job.’

Excellence through Continuous Improvement at Kiremko

Nicole: ‘We are laying a good foundation for working at Kiremko.’ It does not stop at good “on boarding”. At Kiremko, “Continuous Improvement” is one of the four strategic pillars. Nicole: ‘We believe that properly utilizing and developing our people’s knowledge makes a major contribution to their job satisfaction and is a prerequisite for Kiremko’s continuity. This way, we ensure that we stay at the forefront of the market while continuing to engage and retain our employees.’

Internal career progression

The management team serves as a great example of internal growth within the company, as both Paul and Marcel started out as draftsmen. A current example involves a young colleague who joined as a draftsman and aims to change to project manager. Nick: ‘Together with him and his supervisor, we assess the necessary training and education. We create a personalized development plan and monitor progress.’ Nicole: ‘This is ideal for us. It builds valuable experience and knowledge about our products, which can then be applied in different roles, helping retain employees within our organization.’

Accessible Learning at Kiremko: Adapting to Diverse Needs

However, not everyone seeks training and change, which they can indicate. The Kiremko Online Academy is accessible and largely optional. Nicole: ‘Not everyone has access to a computer or the desire and time to continually learn.’ Nick adds: ‘That’s why we converted a space in our manufacturing hall, installing two computers. Now, production staff can also take online courses between shifts, especially during quieter periods.’ By early 2024, 86 employees had already participated in some form of training.

Another example of how colleagues continue to learn from each other is the initiative ‘House of Knowledge’. During these sessions, a colleague shares insights about their work. This takes place every quarter. Nicole explains how it operates: ‘We announce these sessions through our internal app and office screens. Colleagues can choose to attend. On average, fifty to seventy colleagues participate, learning about ongoing projects and developments.’

Empowering Growth Through Knowledge Sharing

Nick concludes: ‘Internal knowledge sharing is crucial to us. We also pair younger colleagues with more experienced ones. Our learning principles emphasize learning through guided practice, mutual learning, and formal education. This philosophy is reflected in all aspects of our work.’

Kiremko, Idaho Steel and Reyco hosted students from three local secondary schools for an inspiring ‘Experience Day’, where they explored the potato-to-fries process and gained hands-on welding experience under expert supervision.

Discover how HZPC and Kiremko’s global potato processing partnership drives innovation, sustainability, and growth across the potato chain.

Kiremko, Idaho Steel and Reyco have entered a new era of leadership and growth with the appointment of Gerardo Chiaia as President and CEO and Kees van der Drift as CFO. Supported by Investindustrial, the group is uniting its global expertise to strengthen its position as a leader in food processing innovation and integrated solutions.

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment

Quadra Flow's many benefits range from fantastic results on French fries, wedges, and slices, to easy operation and user-friendliness.

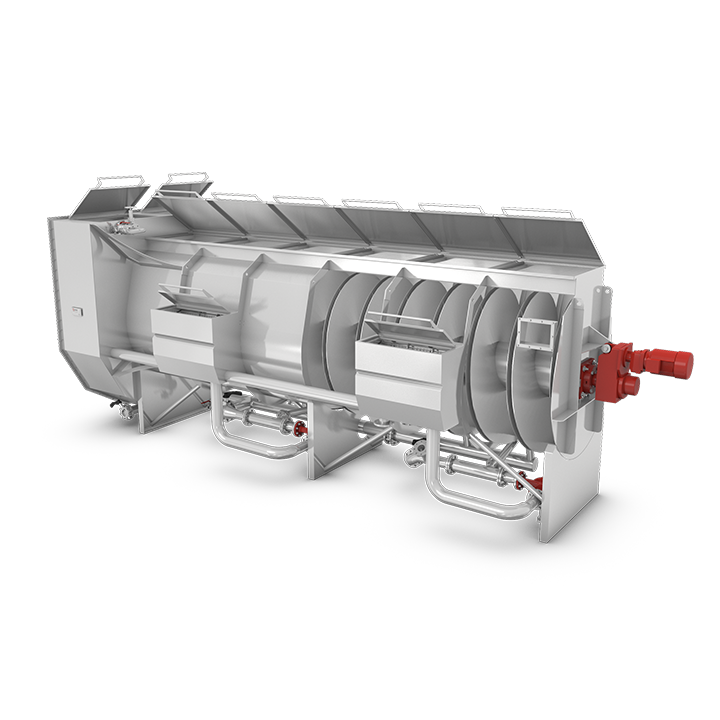

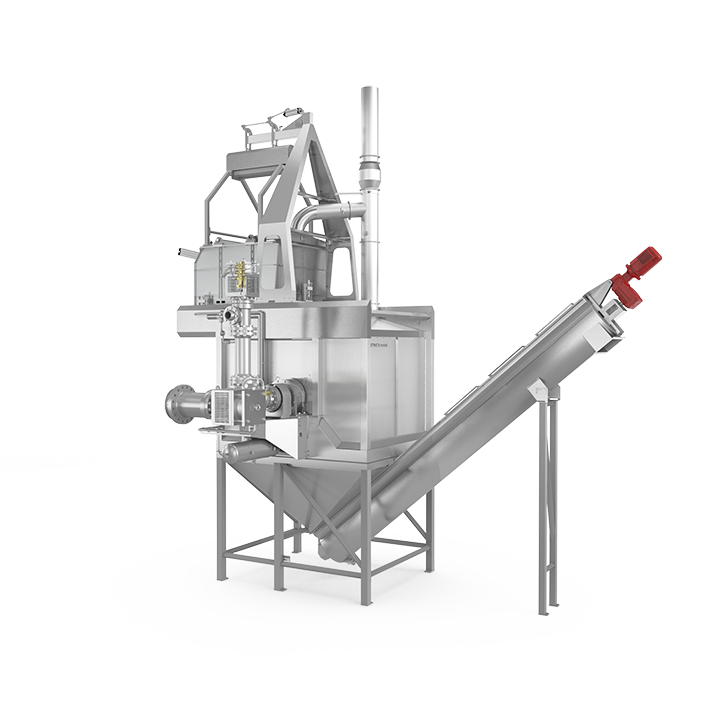

Cooling the product down to the desired temperature to prevent retrogradation is the goal of the screw-type cooler.

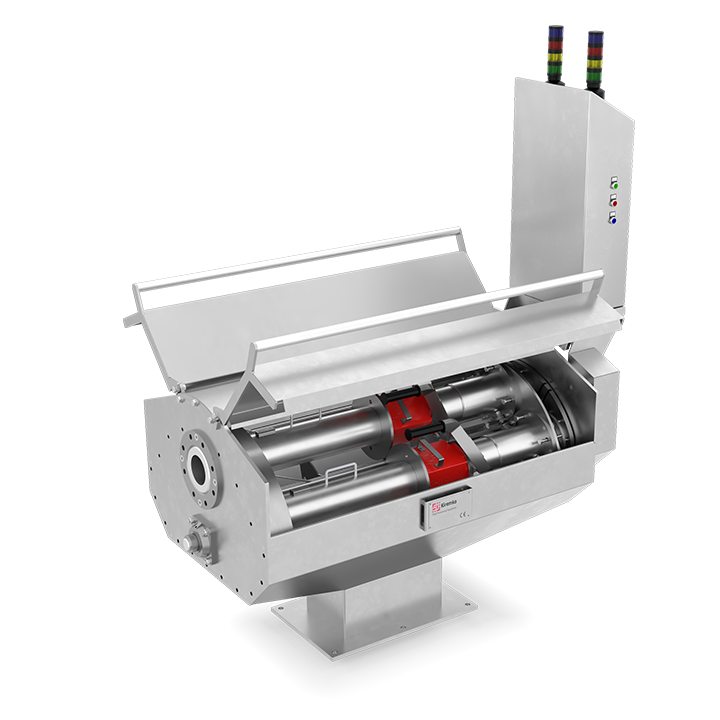

By offering maximum yields at the shortest cycle time, STRATA Invicta sets a new standard in steam peeling systems.