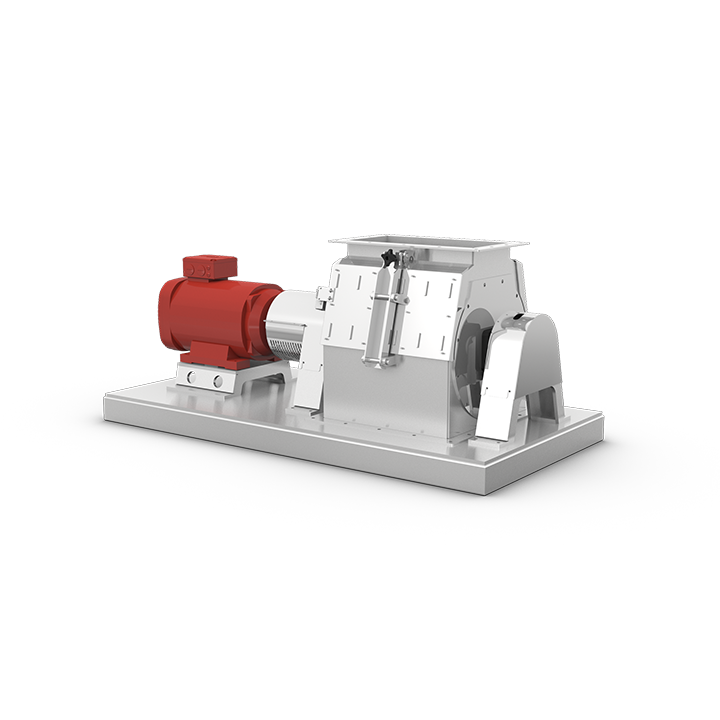

Flake mill / Grinder

Cutting

Milling is the final step in the flake process. The milling machine mills potato flakes into flakes that are as small as 1,6 mm x 1,6 mm and as big as 20 mm x 20 mm. It is designed for high throughput and is extremely flexible.

The FAM Tridis 240P brings capacity, efficiency and quality to a new level.

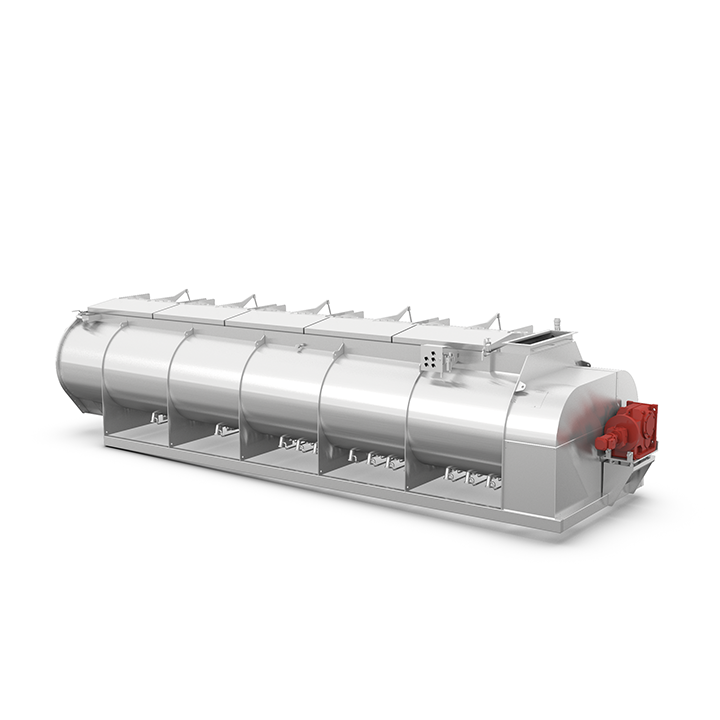

This is the most versatile and time-tested component in the potato mash line as it can produce a large volume and an even cook for a high-quality product.

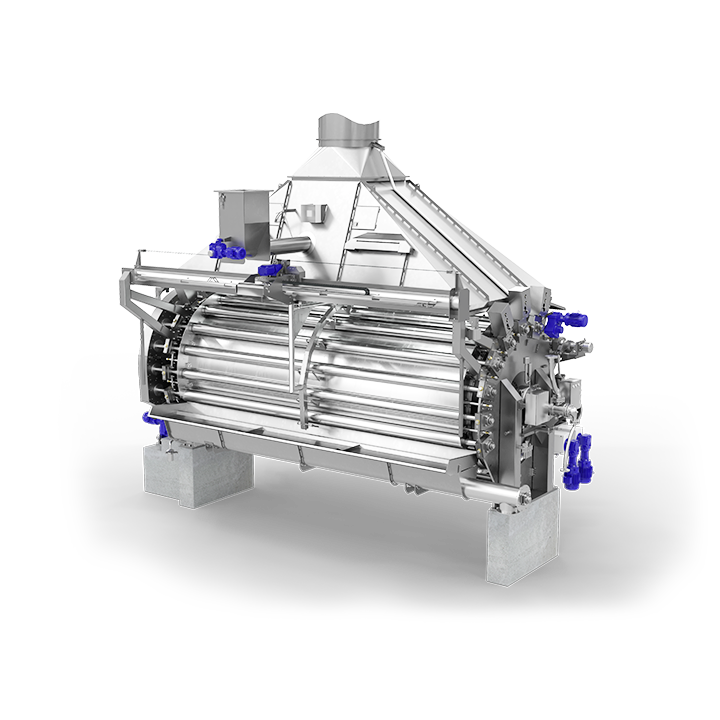

Drum dryers are used to dry cooked potatoes until flakes form. Through cooperation with our partner Idaho Steel, we’ve developed drum dryers with capacities of up to 1200kg/hr. This is 25% more than our competitors, allowing you to make the most of potato by-product.