‘’A perfect example of how craftmanship, collaboration, and intelligent solutions lead to successful outcomes.’’

Theo Sangers - Kiremko’s site supervisor

- Keywords

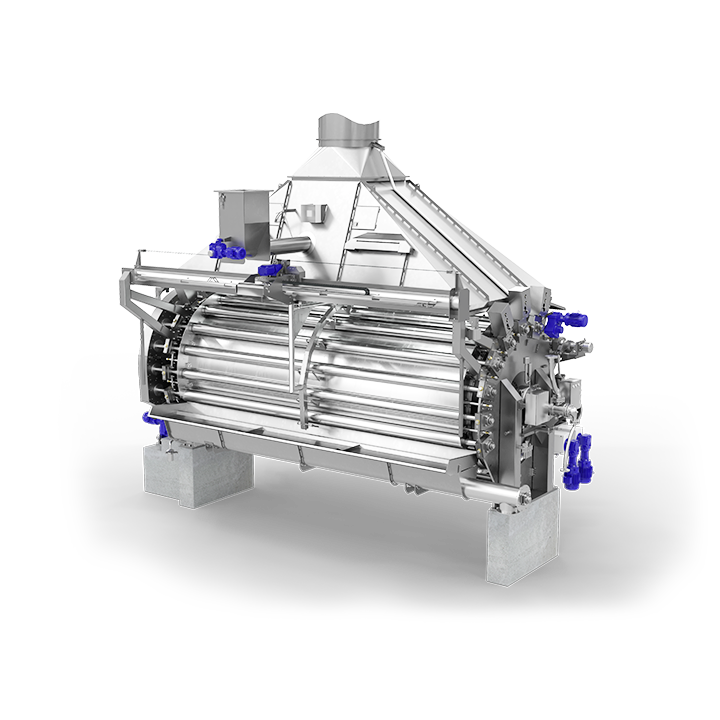

- Drum dryer replacement

- Industrial craftsmanship

- Kiremko McCain project

- Idaho Steel cylinder upgrade

- Potato flake production line

A Remarkable Display of Craftmanship

At McCain Foods in Matougues, France, a remarkable challenge was recently completed: the replacement of a massive drum dryer within a confined and continuously operating production area. This complex project demanded precision, planning, and teamwork. With limited space, strict French labour regulations, and ongoing production activities.

In close cooperation with Idaho Steel and Jan van Dam Group, Kiremko developed a creative and efficient plan. Rather than carrying out the replacement inside the restricted space, the team decided to move the entire unit, including the vapor hood, outside. The result: a smooth and safe relocation of a total weight of 50,000 kilograms.

Under the supervision of Kiremko’s site supervisor, Theo Sangers, a team of seven technicians from Idaho Steel and three specialists from Jan van Dam Group successfully rotated, transported, and positioned the drum. While the work was carried out outdoors, production inside the factory continued without interruption.

The entire project was completed during McCain’s annual summer maintenance period, within the planned four-week schedule. The line was successfully restarted in week 35, exactly as planned, without any production delays or unexpected challenges.

This project showcases the power of collaboration between experienced partners. Thanks to the combined efforts of McCain Foods, Idaho Steel, Jan van Dam Group, and Kiremko, a complex challenge was transformed into a seamless execution.

Theo Sangers: ‘’A perfect example of how craftmanship, collaboration, and intelligent solutions lead to successful outcomes.’’

Drum dryers are used to dry cooked potatoes until flakes form. Through cooperation with our partner Idaho Steel, we’ve developed drum dryers with capacities of up to 1200kg/hr. This is 25% more than our competitors, allowing you to make the most of potato by-product.

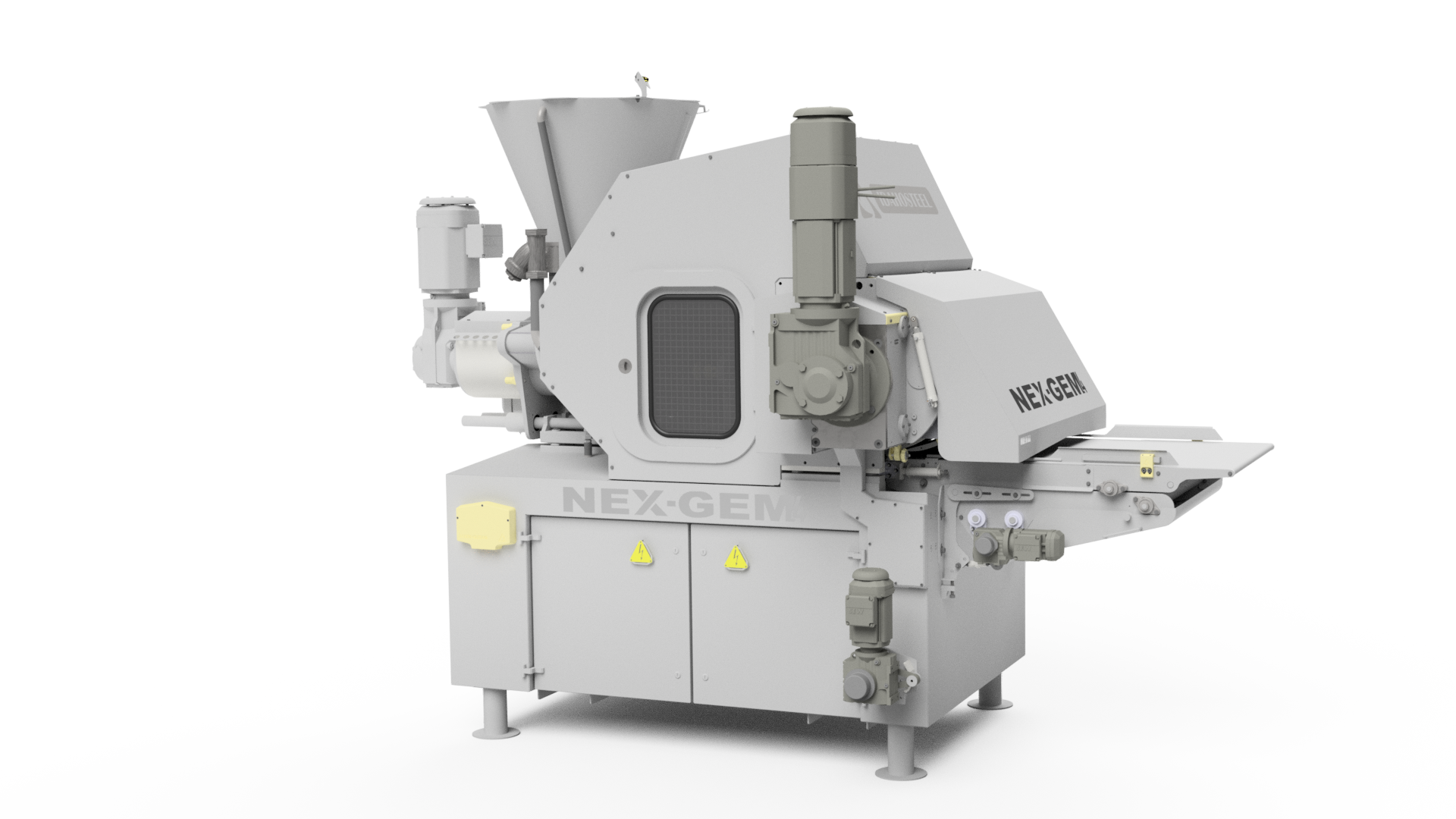

Nex-Gem4 is an ultra-modern rotary former, which is provided with numerous extra features such as Simplified Straight Feed, Increased Production Capacity and Advanced Monitoring. Combined with one of the trusted features like 'Quick-Change Inserts', which provide very quick tool exchange without the need for special tools, this former stands for performance and dependable results.

As the shredder reduces the size of the incoming product, the size of the shred influences both the appearance and texture.

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment