"Our mission is to make tasteful and healthy potato products in a sustainable way"

Carlo Mylle

- Keywords

- Mydibel

- Sustainable

- The Kiremko WeighGuard®

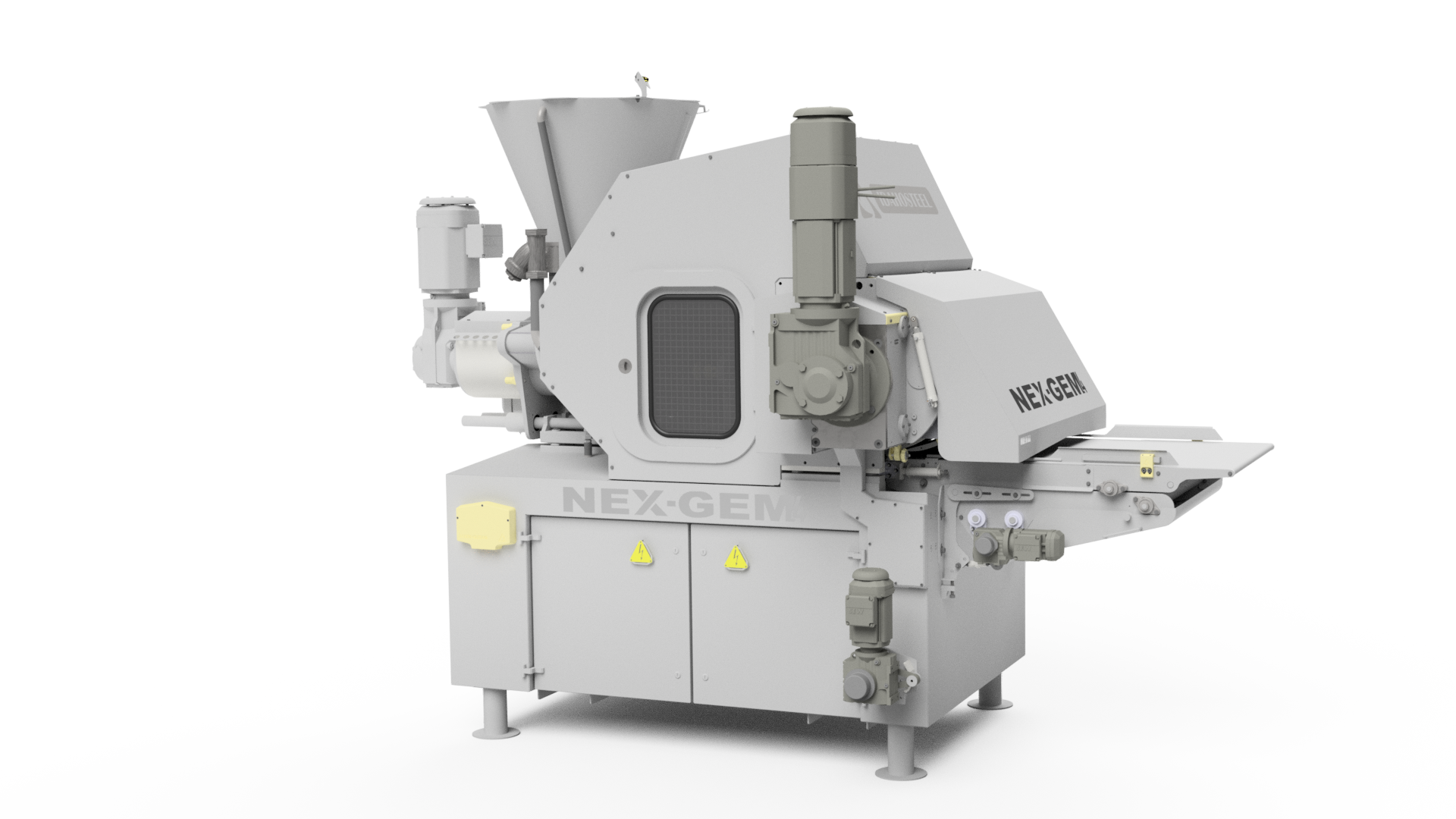

- Idaho Steel Nex-Gem

- Innovation

- Database of knowledge

The Family Footprint of Mydibel

A family man is talking. And a business man. Apart from being one of the leading Belgian potato processors, Carlo Mylle is also a father. And a “pater familias” within the company his father started. “How to stay ahead of competition”?”, the business man wonders. “How to create a mindset for next generations wellbeing?”, the family man asks himself. He is aware of the challenge of serving people, planet and profit all together. No energy goes lost in his Green Factory. But his personal energy is unstoppable. This is the family footprint of Mydibel.

The Kiremko connection

”In 2020 Kiremko built an 8 tons an hour hash brown production line for Mydibel: “I wanted the most modern hash brown line in the world with only top class equipment. With the Nex-Gem former from Kiremko’s partner Idaho Steel and Kiremko’s own fry-by-wire fryer. A unique combination in the market place. My research for this project even got me on a American Football field during the Potato Bowl final, Carlo Mylle says grinning.

“We have some unique solutions in this production line. The first months look very promising, we reached more than our targets and although the capacity is the biggest in Europe, Kiremko built in some Mydibel-specifics that offer us great flexibility in our product range. Kiremko made it work. I personally think that the hash brown will conquer Europe in the next few years. We’re ready for it. No, we’re ahead of it.”

We’re ready for it. No, we’re ahead of it

I built this new production line in my head over and over again. It took a lot of preparation but it payed off

If you are used to doing extra, you ask for extra as well. Kiremko was not just asked to do the job, it had to be done within twelve months. From first draft to commissioning. “We already had a significant contract for the end products at the time we were still in the sketching phase. The pressure was high, but we made it. And Kiremko built it. Their specialists were all over the place after the installation was finished. Now we can look back and be proud.

There are still a lot to improvements possible, but that’s the extra we always do.” Carlo Mylle specifically refers to the contacts with Jon Christensen of Idaho Steel. “He is a family man as well. We have a great connection. The Nex-Gem former of Idaho Steel is performing at Mydibel since 2003 , when we bought our first one. Now we have three of them. I built this new production line in my head over and over again. It took a lot of preparation but it payed off.

“Our mission is to make tasteful and healthy potato products in a sustainable way”, says Carlo Mylle. He and his brother Bruno were raised at the potato processing factory his father started. “We literally lived at the factory. At three o’clock in the morning the steam whistle blew and fifteen minutes later my dad would bang on my bedroom door: ‘what’s taking you so long?!’. I was 19 years old, Bruno 23, he was 49 and he had invested every penny he owned in this new project. We lived at the factory for 17 years. That’s how Mydibel started. Nowadays, 32 years later, we have 650 people on our payroll and we have developed a masterplan towards 2030. By that time Mydibel wants to use the full 100% of every potato.”

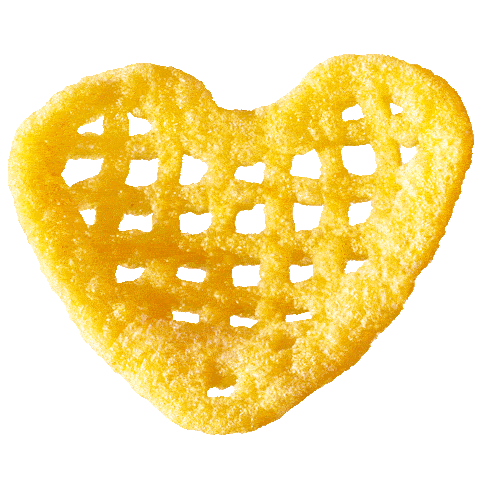

A Kiremko WeighGuard enables accurate salt, dextrose, and flavouring dosing.

Nex-Gem4 is an ultra-modern rotary former, which is provided with numerous extra features such as Simplified Straight Feed, Increased Production Capacity and Advanced Monitoring. Combined with one of the trusted features like 'Quick-Change Inserts', which provide very quick tool exchange without the need for special tools, this former stands for performance and dependable results.

Successfully adding flavourings depends on the accuracy with which the exact quantities of flavouring are applied and bonded to the hot product.