"This new line 4 is a significant improvement again to our line 3 which was installed only 3 years ago."

Celio Zero

- Keywords

- BEM Brasil

- Strata Invicta steam peelers

- Reyco EcoMiser

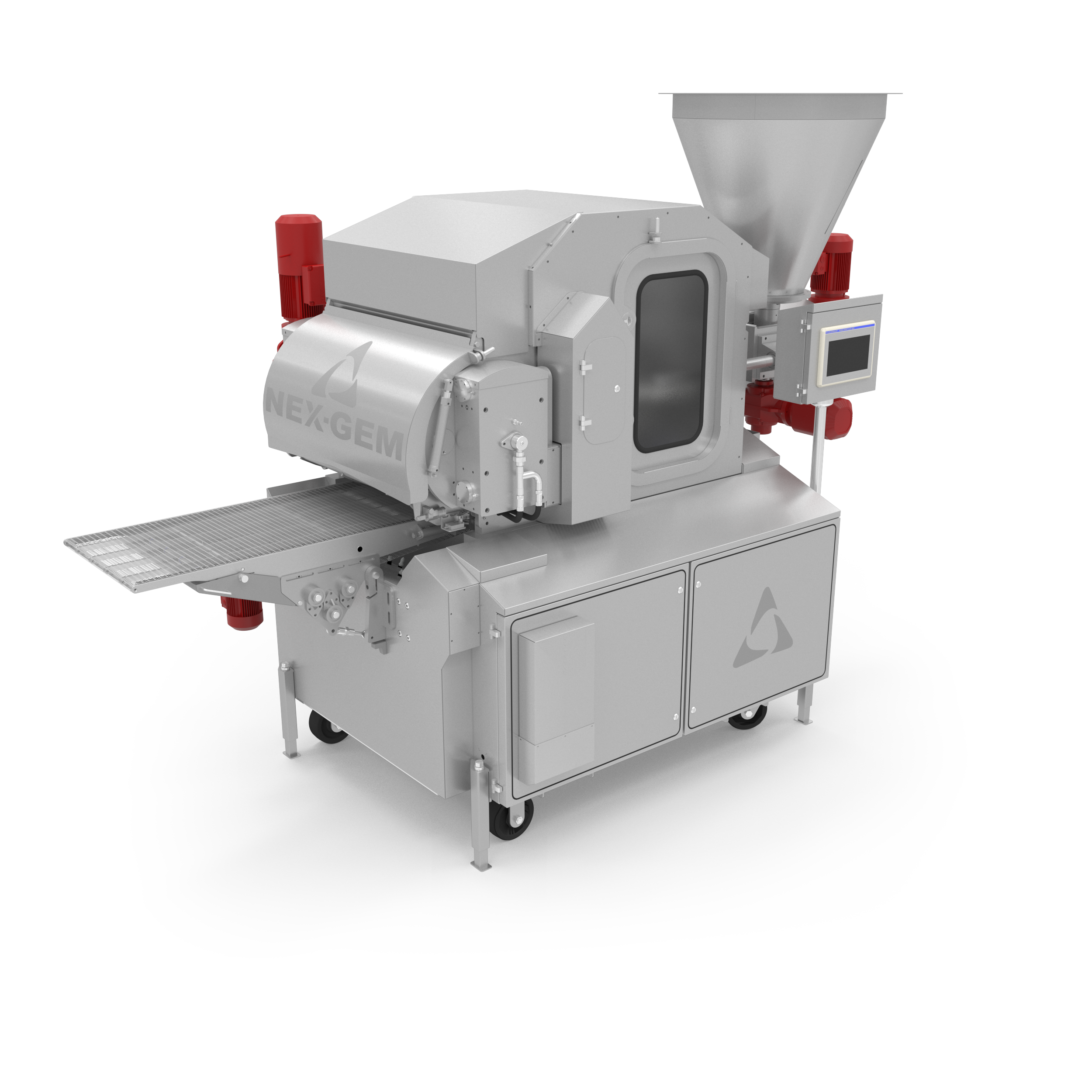

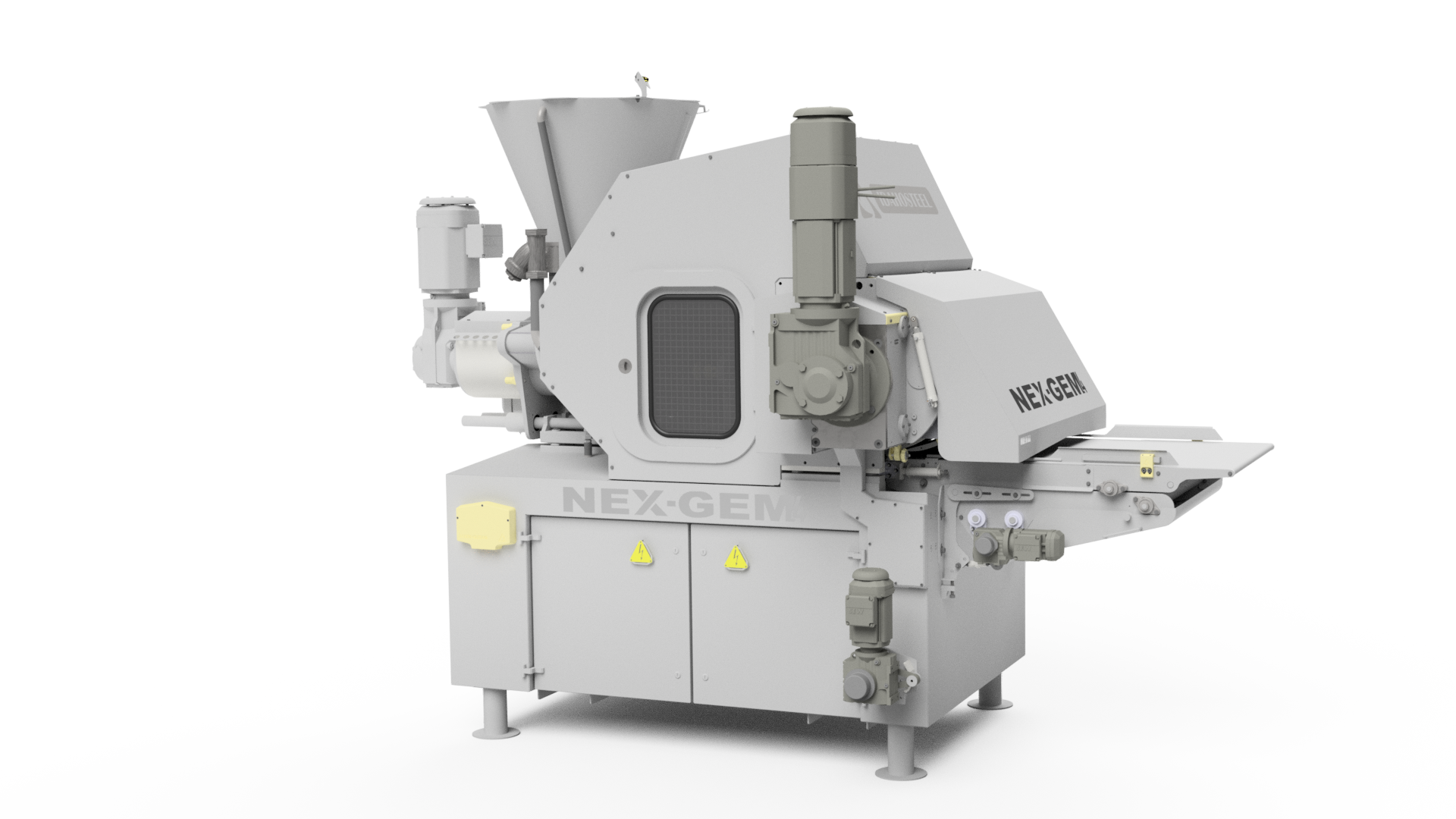

- Idaho Steel Nex-Gem rotary former

- collaboration

Bem Brasil experiences the value of partnership

In 2020, BEM Brasil already opened their fourth processing line with a nominal output capacity of 30 Metric tons per hour. With this, Bem Brasil proves that ambition, production and sustainability can be combined together.

Idaho Steel, together with Kiremko, was selected as the turn-key supplier of the essential part of the French fry processing line and also supplied the formed specialty line from start to beginning.

The benefit of The Triband

With Idaho Steel selected as the turn-key supplier, Bem Brasil could profit from the collaboration between Kiremko, Reyco and Idaho Steel. Kiremko supplied their best-in-class hydro cutter switchers with cutting blocks. Kiremko also designed and delivered the coating application and 2-stage frying system, which is the largest of its kind installed in the French Fry industry to date, having a net width of 3.000 mm.

The new French fry processing line contains two complete STRATA Invicta steam peeling systems installed in parallel. Two large Idaho Steel design blanchers were supplied as well as a SAPP dip system including REYCO EcoVac moisture removal system.

Our partner REYCO Systems supplied its well-known oil removal and recovery system called EcoMiser. Idaho Steel also supplied the formed specialty line from start to beginning. This line will run off the grading and sorting waste from the main line and has a capacity of over 3.000 kgs. /hour of final product.

“This new line 4 is a significant improvement again to our line 3 which was installed only 3 years ago. It exceeds our other process lines in terms of yield, capacity, and quality. With the help of Idaho Steel and Kiremko, we were able to integrate their own latest technologies and innovations as well as those of other specialist suppliers achieving the best available integrated solution. For our next projects, we expect to make more improvements again on every level!”, says Celio Zero, plant manager BEM Brasil

Idaho Steel also supplied the formed specialty line from start to beginning. This line will run off the grading and sorting waste from the main line and has a capacity of over 3.000 kgs. /hour of final product. The line is unique in its configuration in the way that it is able to process both mash-based products such as “Carinhas” (smiling faces) as well as hash brown type product (patties and tots).The industry leading Idaho Steel Next-Gem Rotary Former is able to make a wide variety of shape s at high capacities.

net width of 3.000 mm

Strata Invicta steam pealer

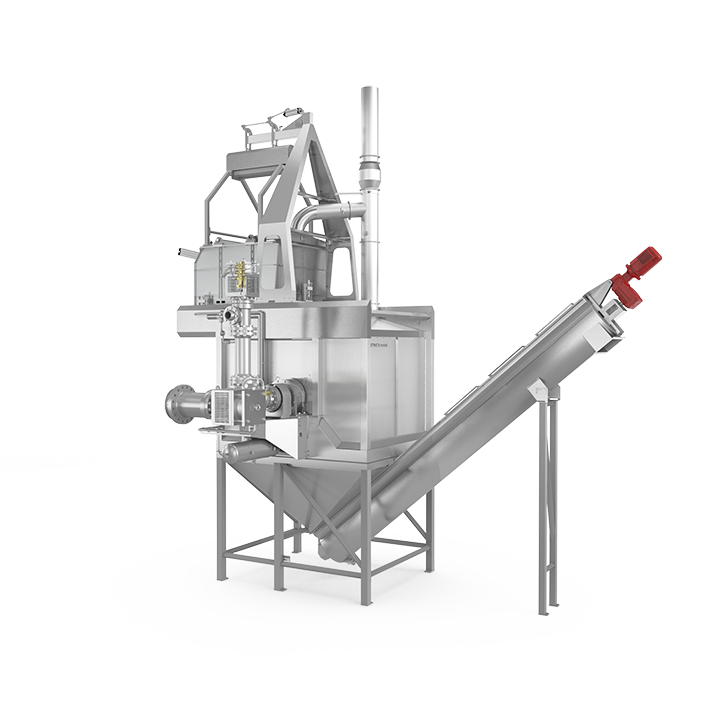

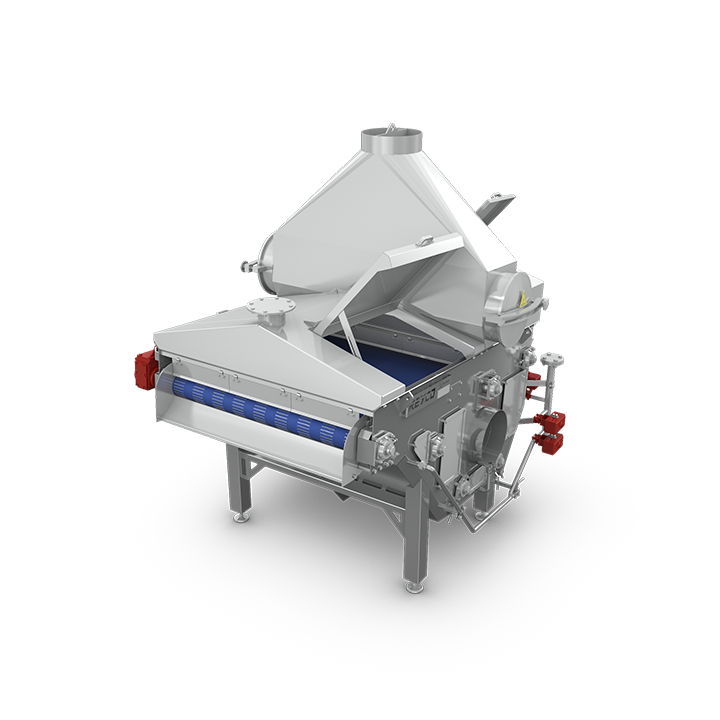

EcoMiser

2-stage frying system

EcoVac

Nex-Gem rotary former

mashed based products

hash brown products

By offering maximum yields at the shortest cycle time, STRATA Invicta sets a new standard in steam peeling systems.

Nex-Gem4 is an ultra-modern rotary former, which is provided with numerous extra features such as Simplified Straight Feed, Increased Production Capacity and Advanced Monitoring. Combined with one of the trusted features like 'Quick-Change Inserts', which provide very quick tool exchange without the need for special tools, this former stands for performance and dependable results.

EcoMiser is a green alternative to traditional methods of oil recovery after frying.

It was the year 2006 when BEM Brasil openend the first, 100% national, pre-fried potato factory in the city of Araxá with a single processing line. From that moment on they have been innovating on a daily basis. BEM is aiming at a great productive potential with an investment that would also bring benefits to the local economy, the potato production chain, and the Brazilian consumer. The need to build a second product line became clear when within three years the market share for frozen pre-fried potatoes had reached 18% in Brazil. With a second line in 2010 and a third line in 2017, 14 years after the opening in 2006, BEM Brasil have expanded their production with a fourth processing line wich has a output capacity of 30 metric tons per hour.

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment