Cutting and sizing

With Kiremko’s finest cutting systems, your operations have reached new heights. At the heart of the cutting line stands the Quadra Invicta. This patented system, featuring KnifeGuard technology and precision-engineered knife blocks, exemplifies innovative, robust, and practical solutions.

You can always expect perfectly cut French fries from your Kiremko cutting line. But your Kiremko cutting line is also the best solution for other applications that require a perfect cut. Your cutting line has already impressed thousands of customers worldwide. Through extensive testing and the use of CFD models, you can perfect the alignment of the flow path, ensuring an impeccable cut with minimal waste. Say goodbye to clogged knife blocks, thanks to the ingenious RFID tag system that monitors the quality of your blades.

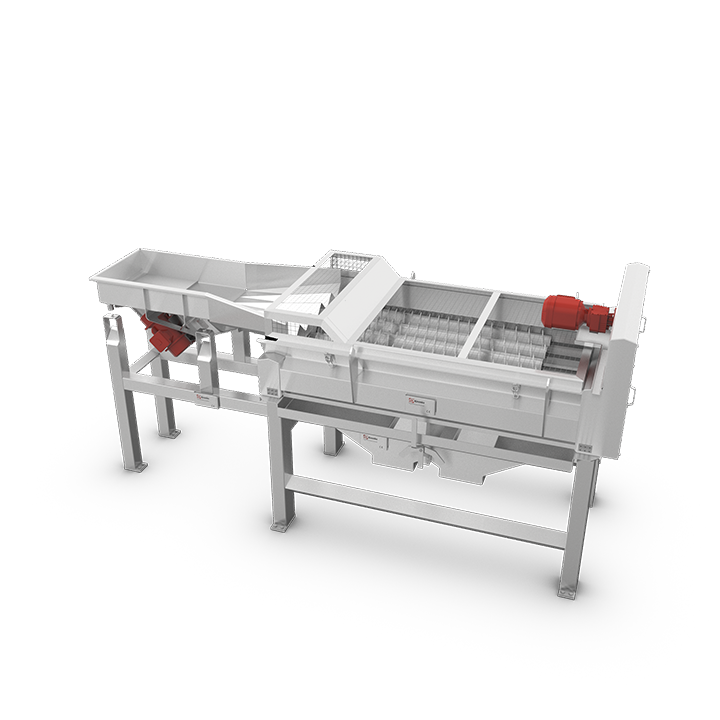

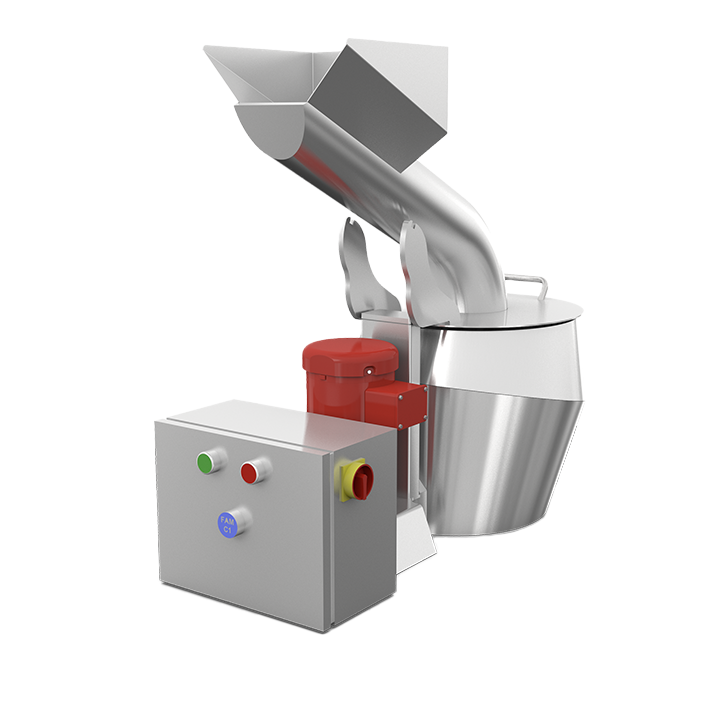

Potato sorter

With the potato sorter, you will be able to sort peeled potatoes using their diameter.

The potatoes are sorted depending on their size using conical rollers fitted with increasing pitches and multiple adjusted valves. This working procedure will prevent products from being retained in the sorter and to maintain a smooth sorting process.

Quadra Flow

Quadra Flow’s many benefits range from fantastic results on French fries, wedges, and slices, to easy operation and user-friendliness. With an exchanger, the knife block can also be changed in minutes, ensuring great quality and a stable process.

Blockages may be removed without stopping the process altogether and any additional tools will not be needed. Thanks to the use of stainless-steel pumps and the use of minimum mechanics, maintenance and water usage have also been greatly reduced.

KnifeGuard

Kiremko KnifeGuard is an innovative knife identification system specifically designed for the Quadra Flow hydro cutter. As the knife blocks and matching alignment tubes in this system are monitored and maintained each day, valuable process information can be obtained.

Using RFID tags, an internal hydro cutter is programmed to detect whether it has the correct combination of the inlet, knife block, and outlet for the selected size of the cut. KnifeGuard keeps track of how long the knife block has been working, making it easier to understand how blades have been used in the field.

Consequently, you will be guaranteed the best possible quality of French fries.

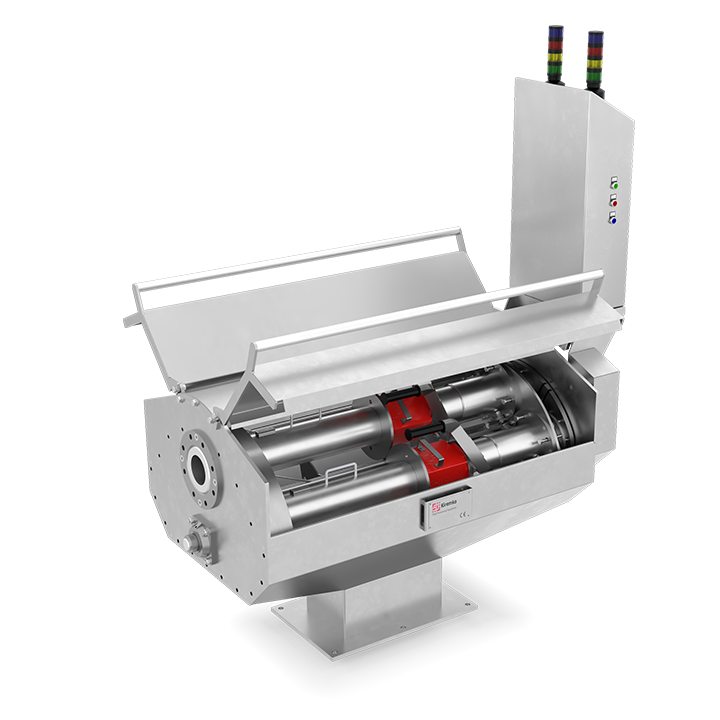

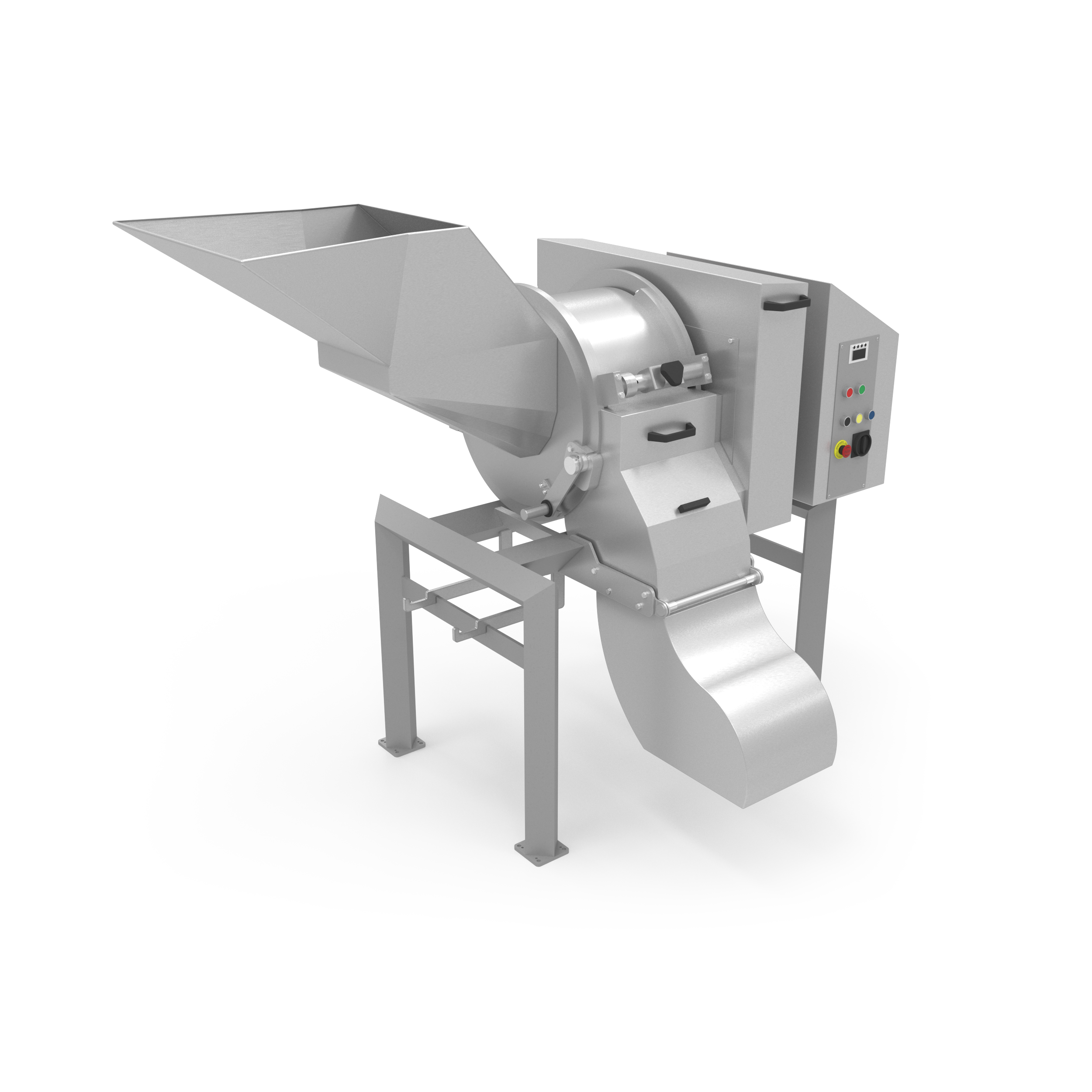

Slicer

The slicer of Idaho Steel is used to size potatoes for processing. By slicing the whole potato, blanching time and product waste are reduced.

A more even product cook is achieved. The slicer is positioned in the production line before the blancher. The product is gravity fed into the slicer through the inlet hopper. As the product passes into the spinning processing chamber, centripetal force pushes the potato to the outside of the chamber where the stationary knife slices the whole potato. The slices are ready for blanching.

Cutting machine FAM Tridis 240p

The FAM Tridis 240p is a new generation of tridimensional dicers designed by FAM. A wide variety of cutting tools make slicing, strip cutting and dicing possible with only one machine. Together with our partner FAM we can offer you various mechanical cutting machines to cut potatoes in three-dimensional shapes, slices, dices, ribbed slices, ribbed chips, extra-long chips, or other variants.

Exchangeable knives offer all thinkable variations. During the designing of the FAM machines and their cutting tools, all factors affecting the cutting quality are explicitly taken into account. This way, you are assured the very best yield, with the least possible cutting waste. For each production capacity, matching machines are available, which can seamlessly be built into each Kiremko process line. Consistent separation of moving parts and production surfaces ensure optimum ease of cleaning and operation.

FAM Tridis 240P: Bringing capacity, efficiency and quality to a new level. High capacity dicer, designed for the very demanding French fry industry. Compared to other available cutting machines, the FAM Tridis 240P increases capacity by 10% to 40%. Perfecting the product flow has led to an excellent cut quality and yield, with less slivers and fines. Excels in the most crucial performance indicators: cut quality, capacity, hygiene, maintenance and simplicity.

FAM Centris slicer

The FAM Centris is perfect for centrifugal slicing of potato and vegetable chips. Tested and in production since 2015, the line has an ever-expanding range of blades in all shapes and sizes.

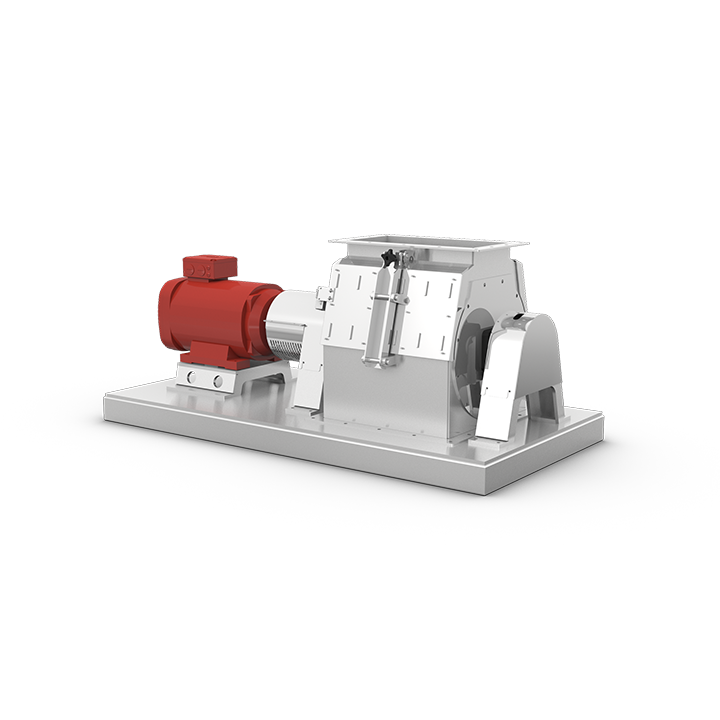

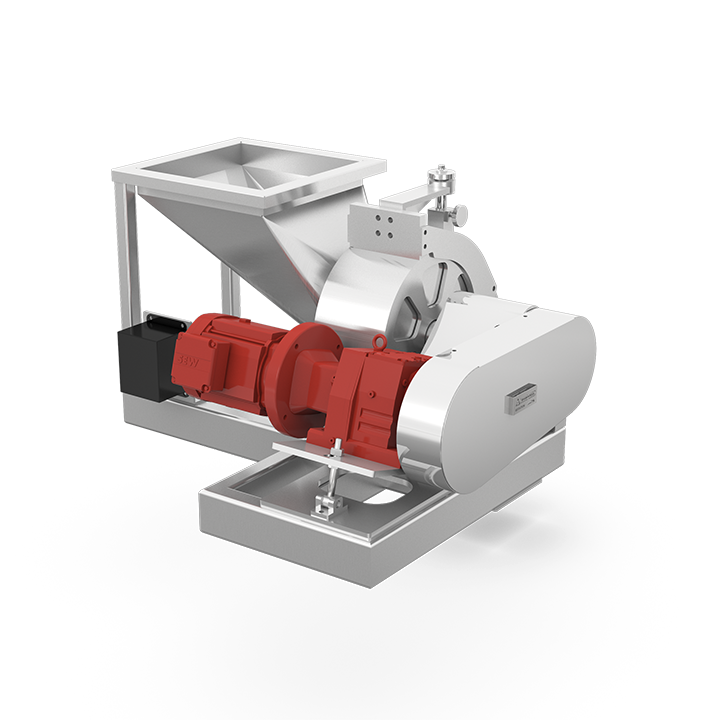

Flake mill / Grinder

The last step in the flake process is to mill the product to obtain its final properties. The machine is designed for high throughput and is extremely flexible, milling potato flakes into sizes ranging from 1,6 mm x 1,6 mm to 20 mm x 20 mm.