Peeling back the layers: A steamy dive into Potato Peeling Excellence with Eric van Oorschot of Kiremko

In the potato processing industry, steam peeling plays a crucial role. The efficient and effective removal of the skin is very important to achieve high yields. Eric van Oorschot, a specialist in this field and employed by Kiremko for more than a total of 25 years, shares his insights and experiences on potato peelers. Read on to find out how Eric got into the industry, how Kiremko has responded to customer needs and what the future holds for steam peeling.

- Keywords

- Strata Invicta

- Innovations

- Steam Peeling

- Eric van Oorschot

Eric van Oorschot is a man with a rich history and a deep love for arable farming, with potatoes as his favourite crop. “I was born in 1961 in Achthuizen, a small village on Goeree-Overflakkee, where I still live today in the house where I was born. After primary and secondary school in Middelharnis, I started studying mechanical engineering at HTS Rotterdam and graduated in 1983. I am a proud father of three sons and have been happy with my girlfriend Myriam for 7 years now. We live alternately in the Limburg hills and on the flat island surrounded by water in the southernmost tip of South Holland near the border with Zeeland. I realise this is a luxury as many people choose both these environments as holiday destinations.”

Eric emphasises his passion for his work, but also his love of travel and culture. He enjoys visiting museums, churches and castles, both during holidays and in his spare time. He also has a penchant for reading, cooking and exciting movies and series.

Clearly, Eric’s passion goes beyond potatoes; it encompasses arable farming in general. However, potatoes have a special place in his heart: “It is not just the love for potatoes, but rather the interest in arable farming as a whole. Still, potatoes are my preferred crop because of their versatility. You can do anything with them, from wallpaper glue to vegetable protein and, of course, Fries! Potatoes are a challenging crop to grow and all over the world you see a lot of problems. The Netherlands leads the world in terms of total potato infrastructure, although that realisation is not always in the minds of the average city dweller.”

Family matters

The love for potatoes is not only expressed in Eric’s work at Kiremko, but also outside. Together with his brother, he runs an arable farm and they also grow potatoes…:

“Together with my brother, I run an arable farm where we also grow potatoes. I invite everyone to take a look at our website www.vanoorschot.biz to see what we do. It actually feels like I have two jobs. There is considerable overlap between my work at Kiremko and my work on the farm. My knowledge of arable farming is of great value to my work at Kiremko. In addition, my entrepreneurial mindset, which I have developed through running our farm, helps me to approach business challenges from a practical perspective.”

After graduating from HTS, Eric started his career in the potato processing industry. The industry he is still active in after all these years:

“My first job in the potato processing industry was at Fri-D’Or in Bergen op Zoom. After my graduation, I still had an internship to complete, and there was an internship available at a recently started French fries factory in Bergen op Zoom. It was close by and I was available as an intern. I started with special projects in the maintenance department of the packaging department and soon became the head of maintenance in packaging. Later, I became project manager for new construction projects, including the Fri-D’Or factory in Tilburg. During that period, I ended up in the French fries industry, which was just starting to grow significantly and become highly professional. Besides McCain, Fri-D’Or was one of the few producers in continental Europe capable of making French fries for fast-food restaurants. My time at Fri-D’Or was very instructive. I learned about setting up production lines, quality systems, quality systematics and developing new products with corresponding production lines.”

Coming full circle

Eric is known to many in the potato processing industry and his face is often recognised by people working in this sector. After his time at Fri-D’Or, Eric did not stop his career in the potato processing industry. Eric explains how he joined Kiremko: “I joined Kiremko in 1988 at the request of Ton Kamerbeek, the former owner. I worked at Kiremko as a project manager from 1988 to 1999. Later, I looked for work closer to home in Zeeland.”

After working at Kiremko for 11 years, Eric sought work closer to home so he could see his children grow up: “Between 1999 and 2006, I worked in Zeeland at Roem van Yerseke, where I was technical manager for factories in the Netherlands, Germany and Denmark. After changes and shrinkage in the fishing industry, I stopped working there. At the same time, I received an offer from Kiremko via a request from Bas Bijman to return to Kiremko. My home situation had changed and leading a reorganisation was not exactly enjoyable now. So in 2006, I started back at Kiremko doing the same work I still do to this day.”

Kiremko has continuously adapted to changing customer requirements over the past decades. Eric explains how this has come about:

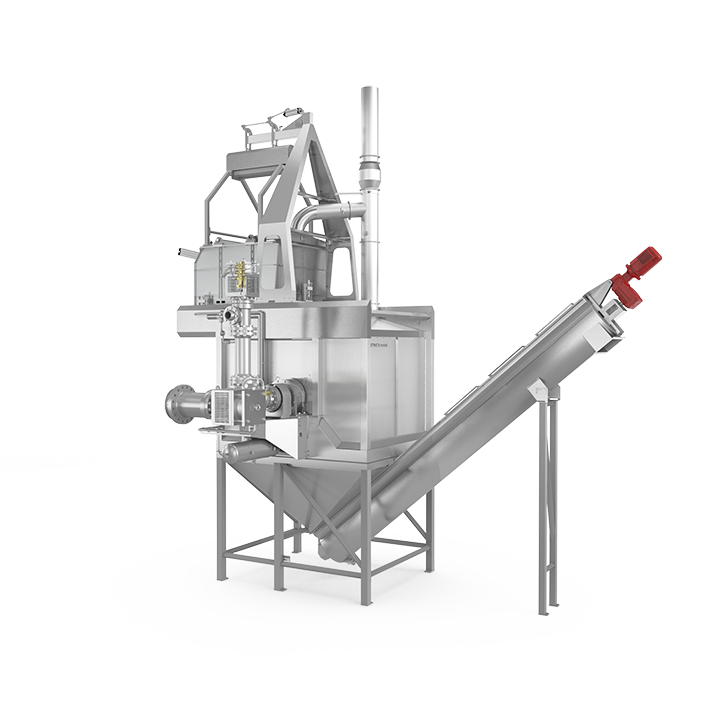

“Yes, we have managed to make continuous improvements in terms of shell efficiency, energy efficiency and operational costs. Coming from Kiremko’s background as technical experts, we have always been careful to improve shell efficiency without compromising on reliability and maintenance costs. Compare it to a Formula 1 car: you can build a lightning-fast car, but if it often fails to cross the finish line because of technical problems, you won’t win a championship. The same applies to steam peelers. High efficiency requires extremely fast pressure build-up and pressure drop, which puts a great strain on pressure vessels, valves, drive systems and control components. That’s why we used NASA quality materials and deep sea technology when developing the Strata Invicta. With our focus on the overall picture of the machine, we have designed a new steam peeler that allows us to meet our customers’ requirements.”

Eric looks back on his involvement in the development of the Strata Invicta, in which collaboration with Titan Projects played a crucial role: “What I remember most from that time is the collaboration with Titan Projects, the builder of our pressure vessels. I had a number of requirements on the table, the most important of which was to have a vessel design with a round shape on all sides, the natural shape of a pressure vessel. A second requirement was that we wanted to have a mechanical design that could be globally uniform. For Titan, this was a new approach. We adopted the toughest requirements from different design standards, including ASME and TÜV AD brand blätter, to create a machine that is uniform everywhere and complies with local regulations.”

Uniformity in spare parts

Eric emphasises that the advantage of uniformity is that spare parts and modifications now have to be properly designed to be interchangeable with older versions of the machines: “We took the toughest requirement for each component and thus designed a machine that is the same everywhere. Only the calculation sheet with the sums to show that the pressure vessel meets the local requirements looks different. The entire series size of pressure vessels of the Strata invicta was set up before even a peeler had been built. This way of thinking and designing also allowed the drive and frequency converter to be completely pre-determined for each peeler size in an intensive collaboration with SEW. For both Kiremko and Titan, this was a new way of thinking, designing in series and not in single pieces. The advantage is that spare parts are identical for each peeler type. Even for modifications, care is now taken to ensure that spare parts are interchangeable with older versions. This requires discipline from the entire design team. Rody de Lang, the ‘product specialist steam peelers’ has been involved in Strata Invicta from the initial design, a hugely committed designer and very disciplined in maintaining this interchangeability.”

We took the toughest requirement for each component and thus designed a machine that is the same everywhere.

The STRATA Invicata has achieved global success thanks to a number of factors. Eric explains why this is the case:

“There are several reasons for the success of the Strata Invicta. First, with the machine we achieved unity of design by thinking serially during development. This approach has helped us create a machine that is globally uniform. We have continuously worked on improving the control software, which has made the machine increasingly reliable and increased our experience with it.

Secondly, by focusing on reliability, we have created a very reliable steam peeler with this machine. In addition, thanks to an inventive design step with very even steam distribution and an even application of steam to the potatoes, we have taken a big step forward in peeling efficiency. Finally, we built and tested the design with peripheral equipment step by step rather than coming up with a completely new and overwhelming revolution. This resulted in a very reliable machine that is now appreciated worldwide.”

Future Innovations

Eric discusses future developments in potato peeling: “An interesting area for future innovations is removing the steam peel residue from the potato without using water. Using plastic brushes for steam peel removal may become less suitable in the future due to food safety and environmental concerns, given the plastic contamination.”

“I am researching other techniques to remove a skin layer. You can think for example of laser, which is used to clean old monuments by removing a very thin layer. With this technique, it is possible to remove a very thin layer almost without heat input. This technique is also already used to engrave text on apples, for example.

No heat input means no cooking ring and no discolouration due to heat of the raw product. The removed layer can be very thin. Unfortunately, so far it is still very small areas that can be treated.”

Eric highlights Kiremko’s ongoing commitment to stay ahead of the competition: “Although we cannot always stay ahead, I think we have already achieved almost the best achievable in steam peeling. The focus is now shifting to automatic control of the peelers and increasing uptime. We want to get a good handle on maintenance costs and aim to maximise machine reliability.

“Customers are involved in new innovations through open discussions that involve both knowledge of the machine builder and the needs and trends in the potato industry. This helps in developing new ideas and innovations. The customer appreciates the input of knowledge from the machine builder, understands the dilemmas the machine builder is struggling with and at the same time, the reverse applies and we learn what is on the customer’s mind.” says Eric.

Eric realises how important sustainability has become these days. Thanks in part to Eric’s expertise and involvement in developing the Strata Invicta, Kiremko has developed a reliable and efficient steam peeler that is appreciated worldwide. “The future of potato peeling looks promising, with an emphasis on minimising water and energy consumption. Kiremko remains committed to exceeding customer expectations and striving for continuous innovation in the potato processing industry. This is the only way we can maintain lasting relationships with our valued customers.”

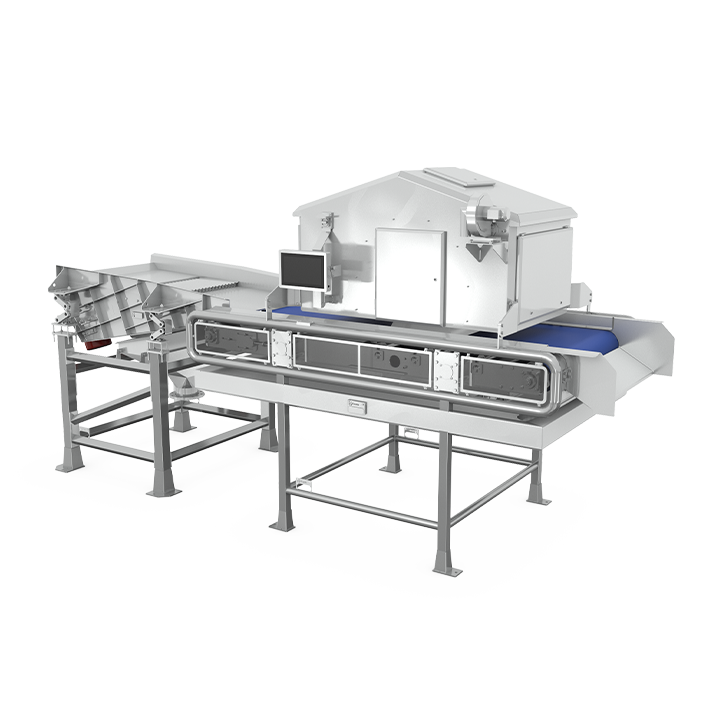

Dry brush machines are used to remove the potato peel after steam peeling.

By offering maximum yields at the shortest cycle time, STRATA Invicta sets a new standard in steam peeling systems.

PeelGuard is an optical measuring and weighing instrument that detects residual peels and the presence of dark, green or black spots.