“We didn’t know of this anniversary of the Kiremko STRATA Invicta steam peeler at the moment we bought it”

Aviko Belgium Project Manager Cor Koole

- Keywords

- Aviko

- Strata Invicta

- Peeling

- Steam peeler

- Mega drum

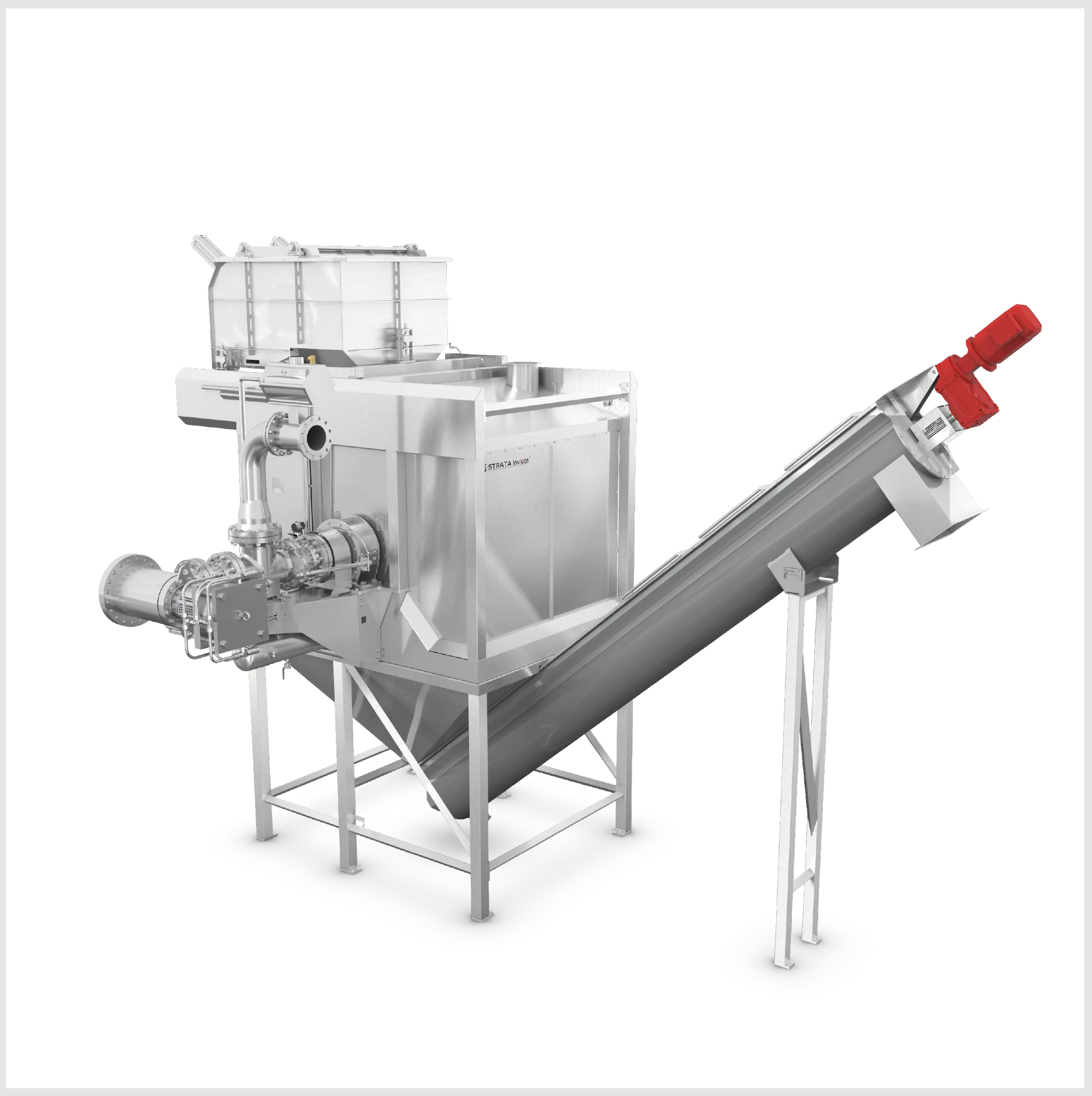

30 STRATA Invicta’s in 30 months

We are proud to announce that we have sold 30 of the best steam peelers on the market in just over 30 months’ time. Made in Europe and the US, supplied globally. This is why.

Aviko settles

for the best

“We didn’t know of this anniversary of the Kiremko STRATA Invicta steam peeler at the moment we bought it”, Aviko Belgium Project Manager Cor Koole admits. “We just bought it because it offers us the highest reliability. We know the Kiremko STRATA Invicta from other Aviko locations. Yield, capacity, operational reliability and total cost of ownership were our main focus. As always – with new major projects, like Poperinge – we had a good look at what the market has to offer and again Kiremko came out as the best. It’s always nice when your choice is acknowledged by others. That is how we see the celebration of the 30th Kiremko STRATA Invicta they sold to us. And we congratulate them with this impressive milestone.”

It’s always nice when your choice is acknowledged by others.

steel steam vessel

• Ultimately balanced and self-correcting vessel positions for high speed mixing giving the best peeling results

• Capacities between 2 up to 90 t/hr

results

• Optimal heat transfer through advanced condensate separation

• 20% smaller cooking ring resulting in a reduction of peel waste up to 10%

environment

• Blow-off condenser for energy recovery up to 1500 kW per ton of peeled product

• Shorter peeling times mean less steam consumption

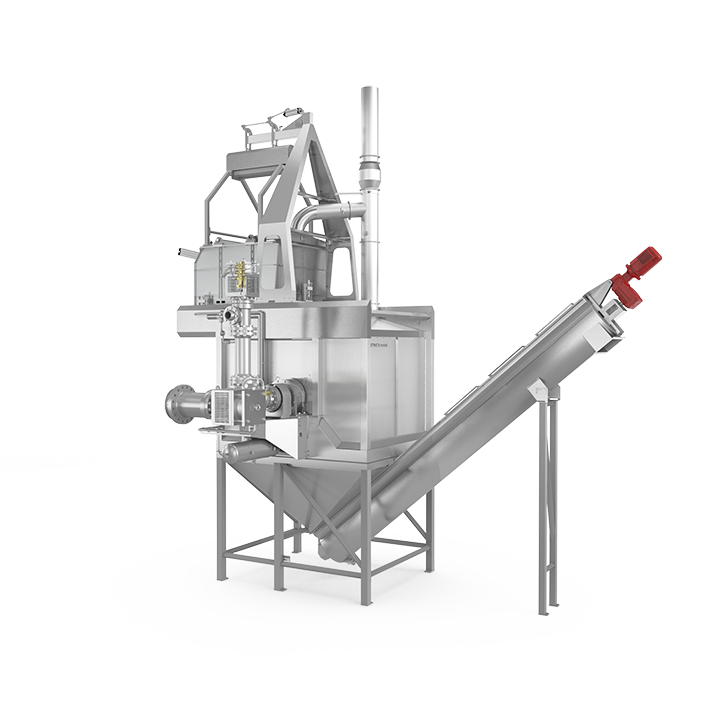

To optimize efficiency of the STRATA Invicta steam peeler Kiremko designed the PeelGuard. Andy Gowing, director of Kiremko: “The PeelGuard is an optical in-line inspection, equipped with a weigh belt, so the exact peel result can be calculated accurately.

Optimized peeling

The system detects the thickness of the removed skin and cooking ring, in order to continuously optimize the steam peeler settings. This way, the PeelGuard guarantees a constantly optimized peeling yield and up-to-date information with respect to quality of raw material used. This information can be made available to the customer’s MES and/or ERP systems.

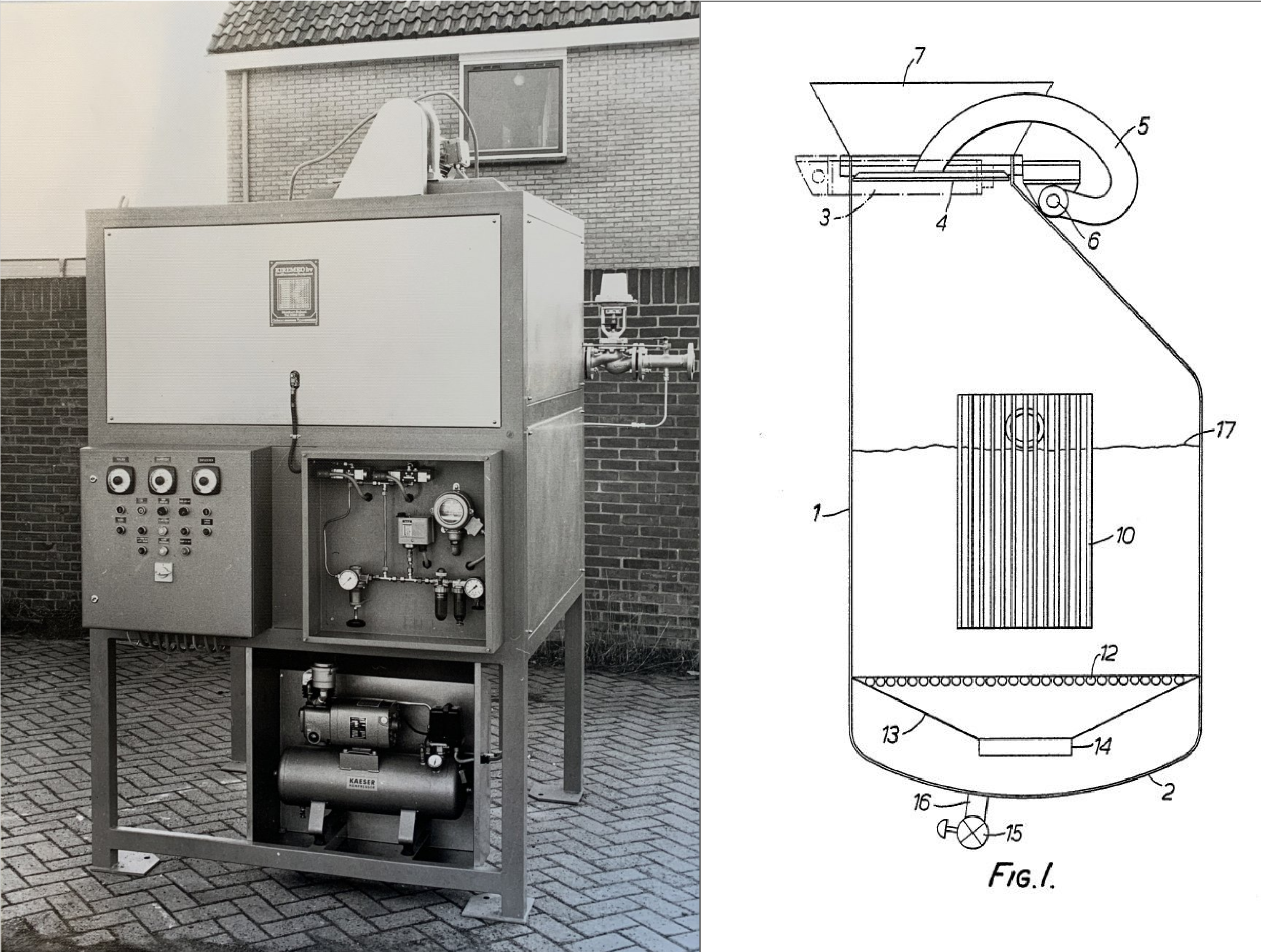

For Kiremko steam peeling is one of the major potato processing steps where their innovation efforts and product development is directed to. This has been the case for many years.

Steam peeling emerged in the late 1960s as a replacement of lye peeling and abrasive peeling. This was better for the environment and with steam peeling the peel residue could be used as high quality cattle feed, as opposed to lye peeling.

Developing the steam peeling process has really been a Dutch affair in which Kiremko was, and still is, one of the most important players. More than 20 years ago the first steam peeler was built in the US, by

Idaho Steel. Nowadays Idaho Steel supplies the America’s and Kiremko the rest of the world.

By offering maximum yields at the shortest cycle time, STRATA Invicta sets a new standard in steam peeling systems.

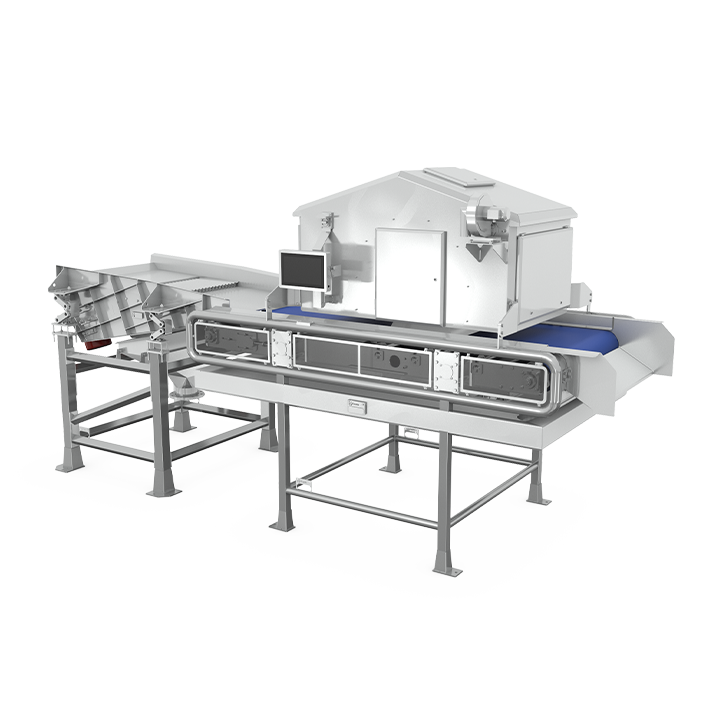

Dry brush machines are used to remove the potato peel after steam peeling.

PeelGuard is an optical measuring and weighing instrument that detects residual peels and the presence of dark, green or black spots.

Interested in our product lines

Would you like to know more about Kiremko or our potato processing equipment? Contact us!

Make an appointment