Frying

At the heart of your potato processing operation lies the transformative process of frying. With Kiremko, you lead the way in acquiring industry-leading fry-lines tailored for every potato product imaginable.

Our commitment to meeting exacting quality standards is matched by our collaboration with Idaho Steel and Reyco, ensuring our machinery extracts the very best from every potato for your success.

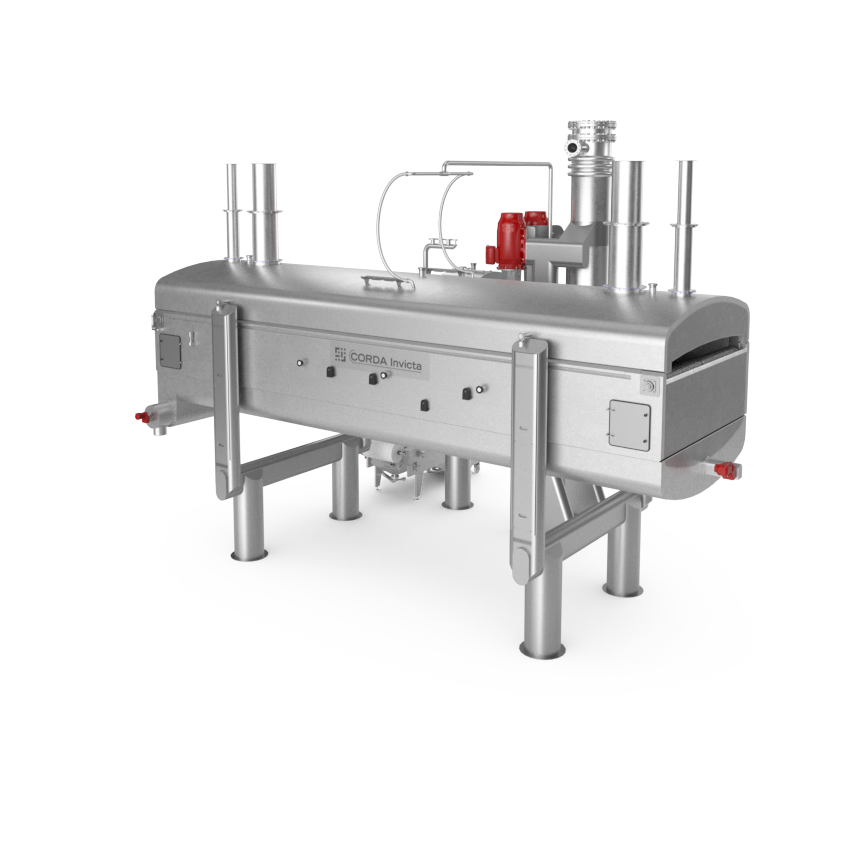

Sustainability, resource conservation, and environmental stewardship are values in the machine development process. The dedication to preserving our planet shines through in the latest innovation, the Corda Invicta fryer — the cornerstone of your fry line. Designed with these core values in mind, the Corda Invicta not only delivers exceptional frying results but also minimizes your environmental impact, setting a new standard for sustainable potato processing.

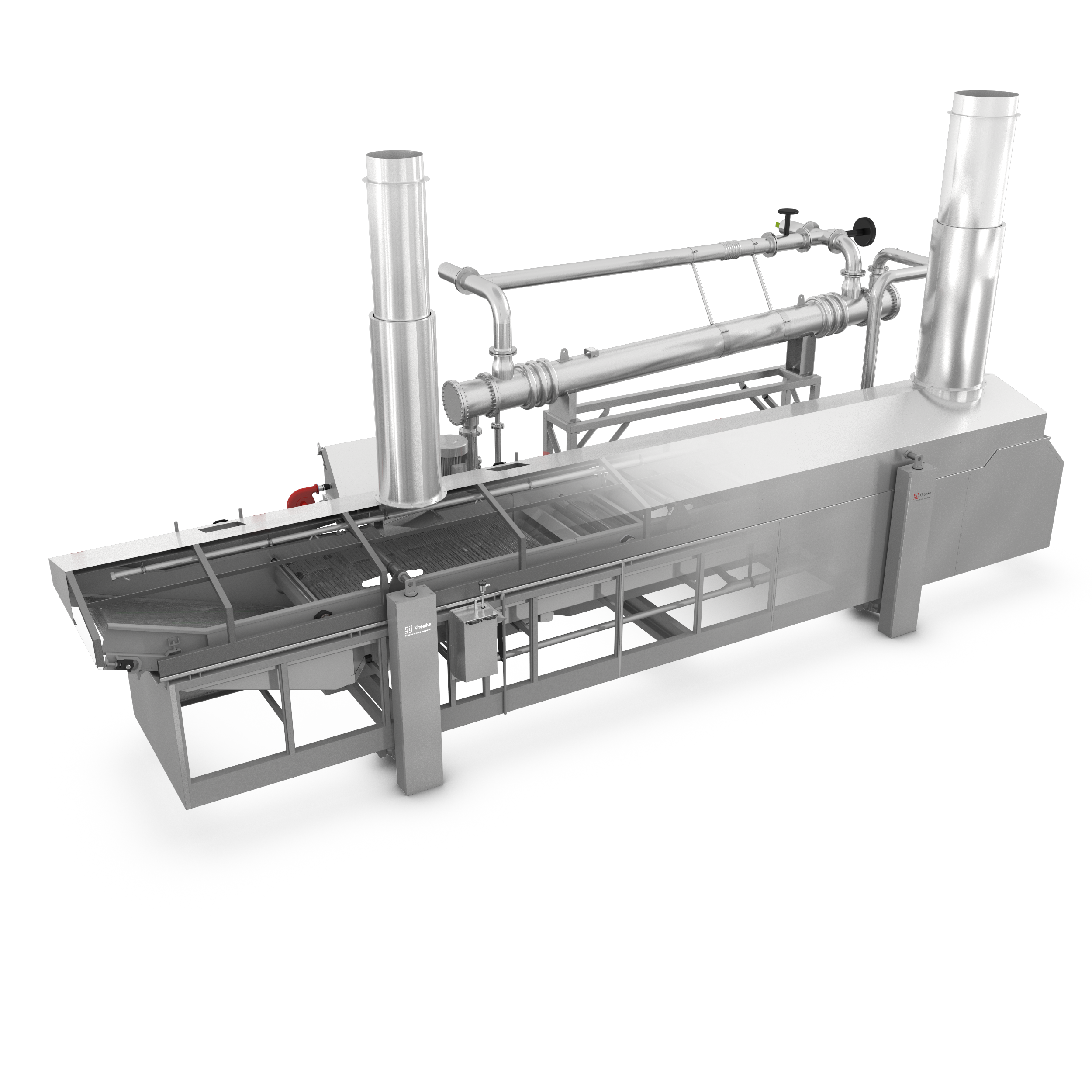

CORDA Invicta

The revolutionary design of the Kiremko CORDA Invicta Fryer is the result of 2 years of intense research, development, testing, and consultation with customers. With the STRATA Invicta steam peeler, Kiremko has yet again set the standard for product innovation. SLIM, STRONG, SAFE, and SUSTAINABLE, thanks to its 30% less oil content, 15% smaller footprint, hygienic design, and low-maintenance belt and pump system, the machine reduces oil content and is environmentally friendly. A trusted technology is redesigned, and new technology is incorporated. The CORDA Invicta, adapted to today’s world, will be presented to the first launching customers by Kiremko this summer. CORDA Invicta Fryer will be available from 2022 and will be suitable for deep-frying (coated) french fries and other potato specialities.

EcoMiser

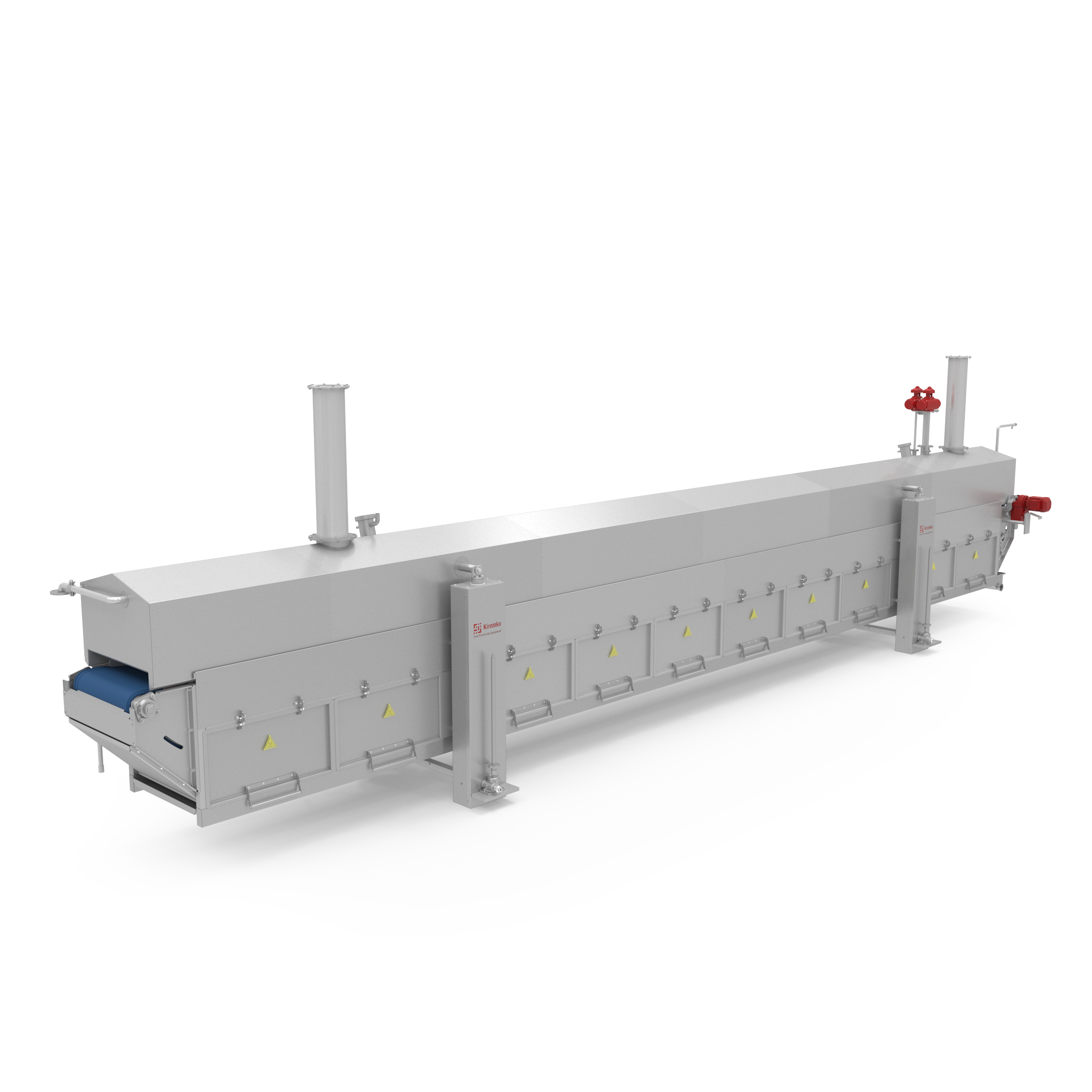

EcoMiser has been positioned as a green alternative to traditional methods of oil recovery after frying.

Using the EcoMiser, you’ll experience the latest advancements in sanitation, noise reduction, and cleanliness, all while minimizing total cost of ownership. Enclosed conveyors with integrated catch pans control oil vapor, reduce noise, and maintain hygiene.

After being pumped out of the fryer, the frying oil is fed to the Primary Oil Filter and filtered. With a Primary Oil Filter, you can simplify your process with less oil and have a simpler circulation system.

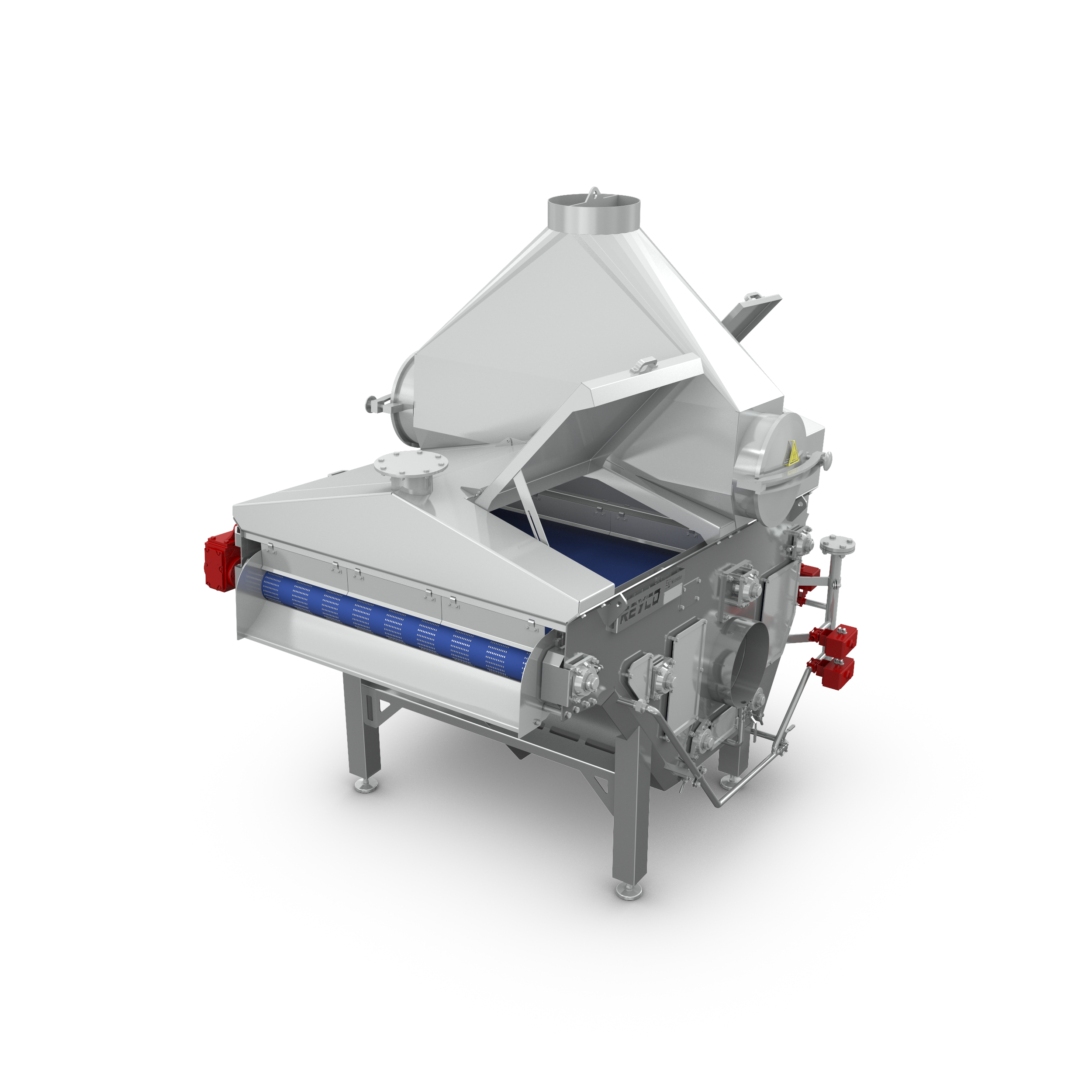

Potato chips fryer

The potato chips fryer has been provided with a well-balanced oil-supply system ensuring the transit of potato chips.

The controlled temperature profile will ensure a perfect frying result. An a-rhythmical paddle system ensures that the potato chips remain free and moving. Two flues ensure a steam layer across the oil, preventing unnecessary oil oxidation. The insulated hood and frame ensure that virtually no energy loss takes place, resulting in a high yield.

Fry by wire specialty fryer

A fryer with an extremely accurate frying technology to ensure that vulnerable products emerge from the fryer, row by row, perfectly coloured and cooked.

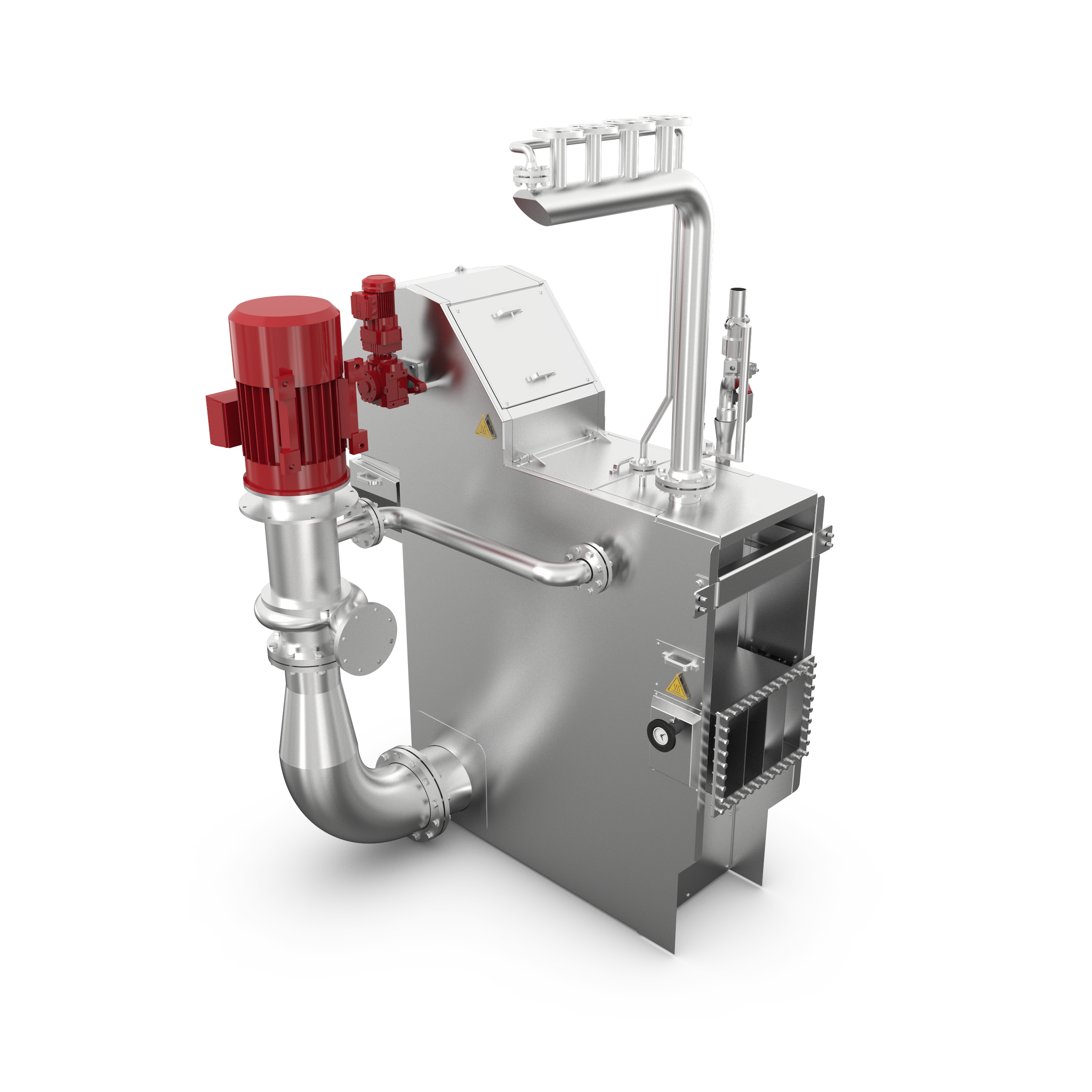

Primary Oil Filter

The frying oil pumped out of the fryer, is fed directly to the Primary Oil Filter and filtered. Adding the Primary Oil Filter to your process enables you to have a simplified circulation system with reduced oil volume.

Pellet snack fryer

The pellet snack fryer is suitable for a wide range of pellet snacks. A dipping conveyor belt takes the pellet snacks through the frying oil and within 6 to 30 seconds, the pellet snacks are fried and expand into their final shape.

Defatting vibrator

The cascade-style defatting vibrator ensures that excess frying oil will be removed from the product, so that it is recovered and put back into the frying system and does not pollute the packaging line

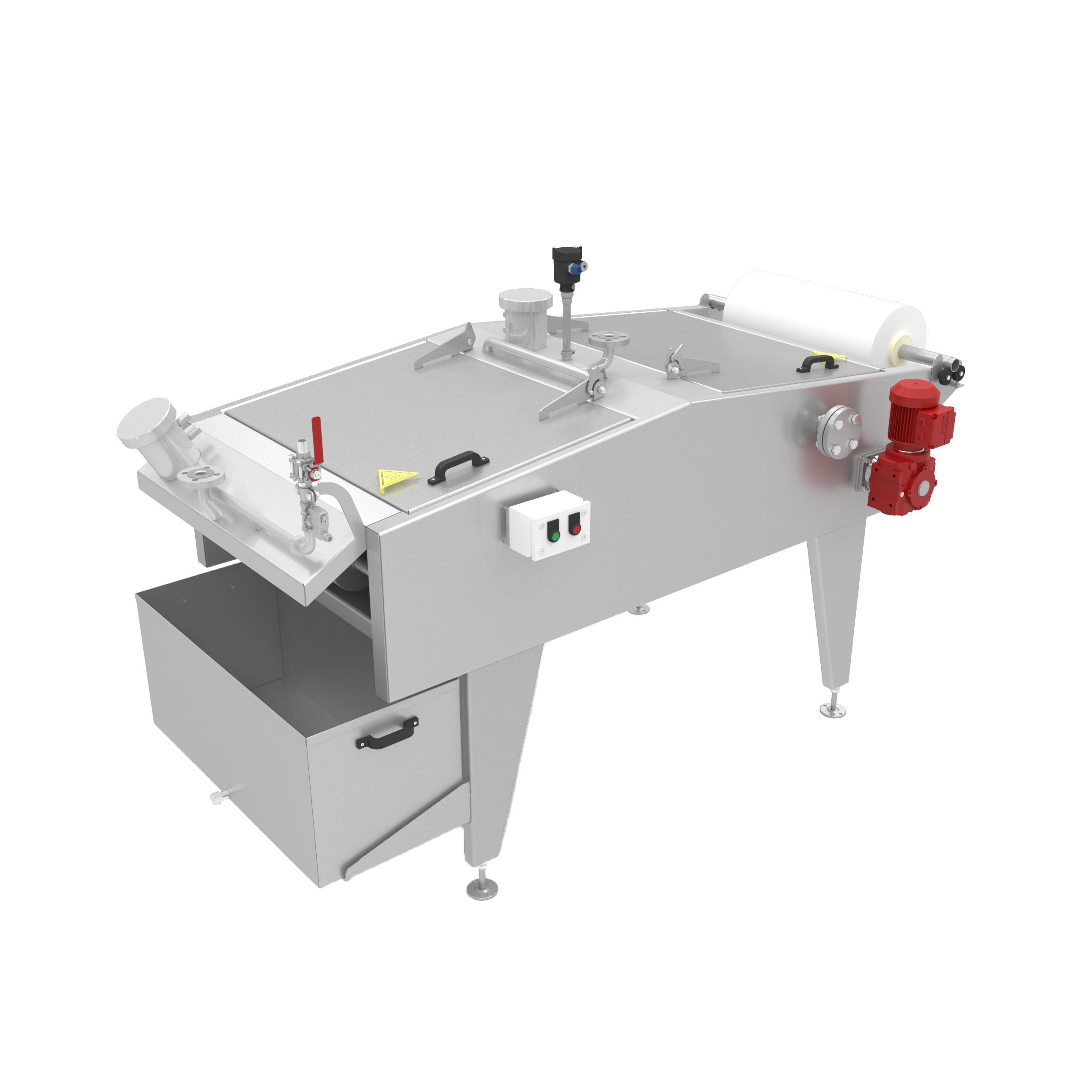

Paper filter

The paper filter will remove the smallest particles of starch from the frying oil.

The oil is filtered by means of a V-shaped conveyor belt on which paper has been applied. The used paper is collected in a special bin with an extinguishing installation; the filtered oil is returned to the fryer. The capacity, depending on paper type and filter size, is nominal 7 – 10 m3/hour.