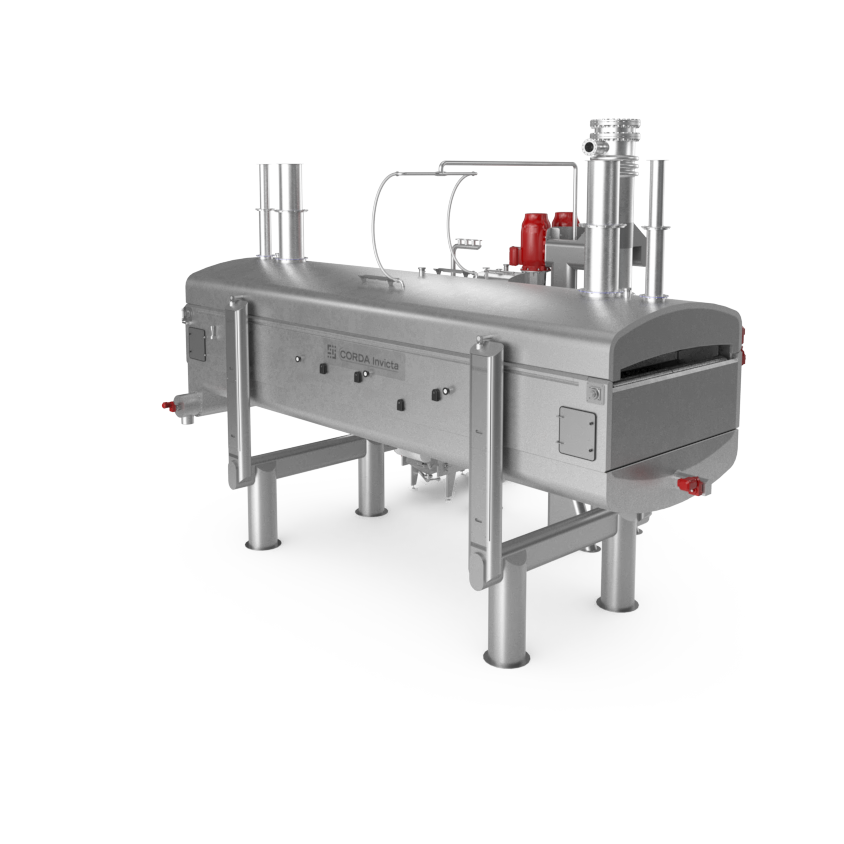

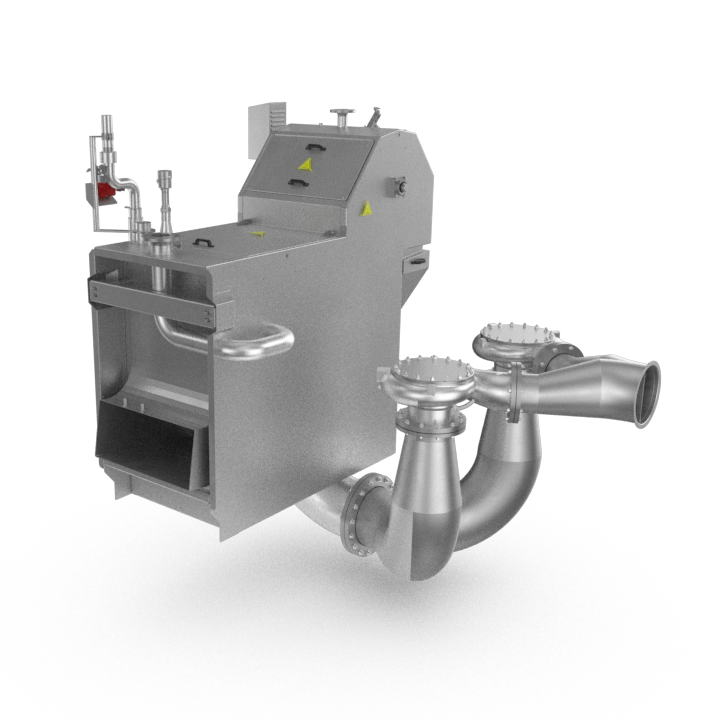

The new Corda Invicta Fryer

Two years of investigation, research, testing and consulting of customers lead to a new, revolutionary design of the Kiremko CORDA Invicta Fryer. At the core of the potato processing line, this beating heart is in excellent shape. With up to 30% less oil content and 15% less factory footprint in comparison to previous designs, hygienic design and low maintenance belt and pumps system, it is slim, strong, safe and sustainable. Trusted technology is redesigned, new technology incorporated. Ready for the future and leaps ahead. We will present the CORDA Invicta to the first customers.

- Keywords

- Industrial Fryer

- Corda Invicta

- Innovation

- French Fries

- Less Oil Use

Oil content and turn over time was the main focus at the start of the research process. Together with the highest flexibility possible. A fryer to fry any product, with the lowest oil content at any time. This lead to a reduction of up to 30% of the oil content of the frying system (not only the fryer, the heat exchanger, the pumps, the plumbing, everything was closely investigated), without any concessions to quality or quantity of the output.

Fryer for all

French fries, coated fries, hash browns, specialties, the new CORDA Invicta Fryer does it all. With its unique optional top-down oil injection, it even offers a wide range of layer thickness to make it the most all-round fryer in the marketplace.

Fryers are meant to perform. Any enhancement that reduces maintenance is appreciated, as long as the fryer continues to operate consistently, delivering a high-quality end product. Customers depend on this, at a moment in processing where all inconsistencies are expensive. The potato is already peeled, cut, blanched and dried, you don’t want any waste or quality fluctuations when you’re frying. That is why the re-engineering of the flow, the injection, the oil circulation and a complete new belt design leads the way in this CORDA Invicta.

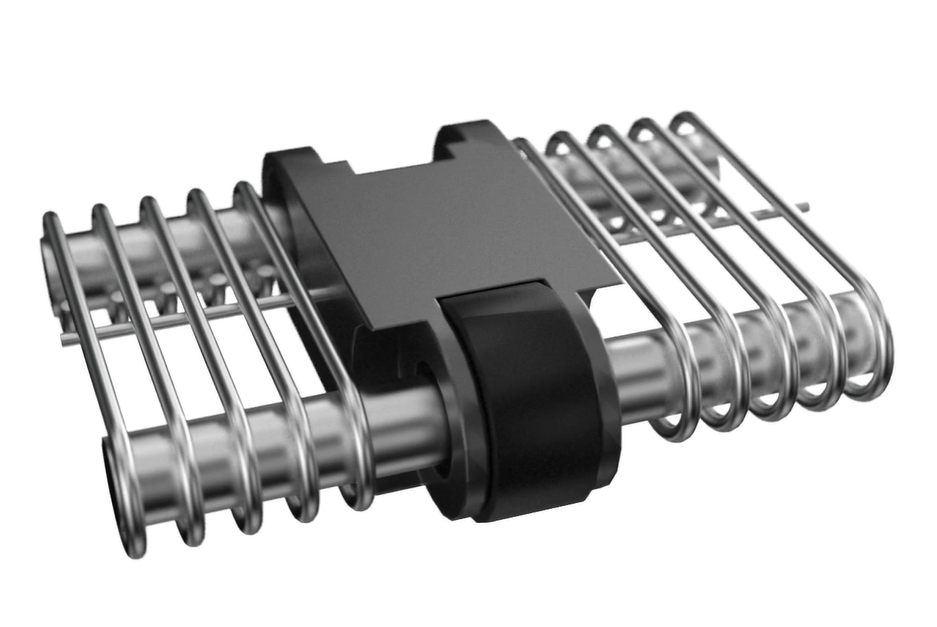

A Belt that lasts

Not a single part was untouched, not a single security was unquestioned. From rock bottom, the oil flow was renewed, which even lead to a successful patent application. The belt in the fryer has a closed chain, completely new, with low maintenance rolling instead of dragging. In every way, this new fryer has a solid base, all aspects of the frying process are built on expertise and experience. Over 50 years of building fryers created a strong vision on strong solutions.

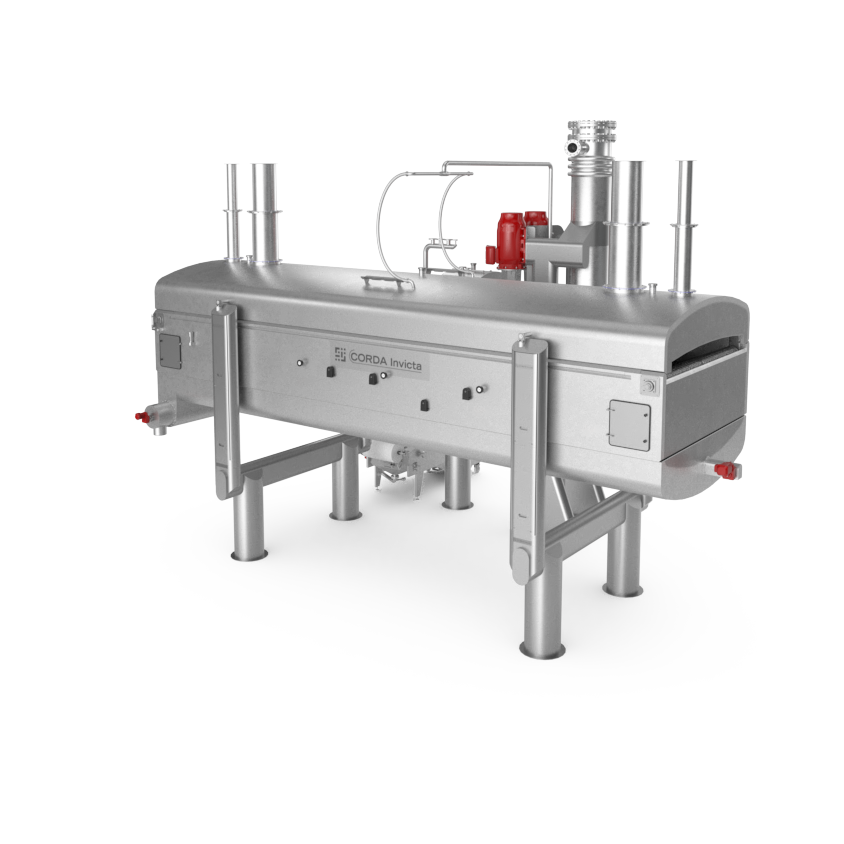

Safe operation

This is where heat and product meet. So safety is a very important part of the customer’s choice. With the CORDA Invicta, safety was a basic demand from day one. Our specialists went to an inspiring location near the Kiremko HQ, to start off with a clean sheet. And safety was one of the first words on the whiteboard. The results of that awareness can be found in an ingenious system of controls, connected to the dedicated control system in the fryer. Apart from that, the hood and bottom of the fryer can both be opened for cleaning purposes, but again, safety comes first. So controls only allow safe operation.

Food safety

The inspiring location near Montfoort offered a lot of hospitality as well. The internal and external experts, but above all, to customers. Their input was vital to the new design of the fryer and safety turn out to be one of the main points of attention for them. In terms of food safety, the CORDA Invicta has a redesigned frame and all flat surfaces are eliminated from the setup.

Heat recovery is no new territory to us. We have built heat recovery systems – from fryer to dryer – since 1987. Together with that added value, the insulation of the fryer and the compact oil circuits show high scores on sustainability. The highest level of automation technology makes sure that no energy is wasted and temperature and status of the fryer are close to the optimum at all times.

Lowest TCO

The most effective turnover time, not only in quality of the end product, but also in efficiency of the process. Innovative solutions are built in, to avoid quality loss of the oil, during short intervals or product switches, when no product is in the fryer. All these smart sustainable improvements lead to a lower Total Cost of Ownership, for the customers profit and for our planet.

Oil filtering and quality

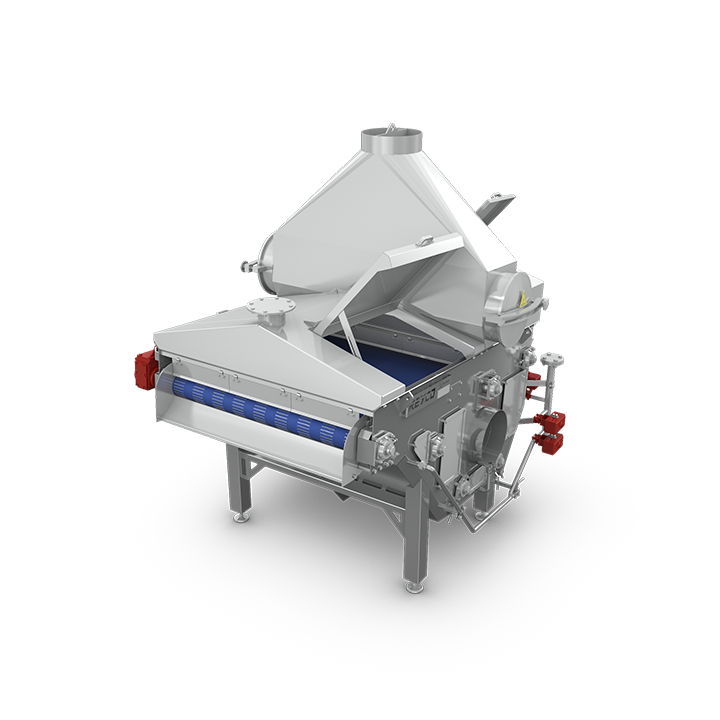

Primary Oil Filter

Two years ago, we launched the Primary Oil Filter, on the Interpom trade show in Belgium. The POF is an efficient scrape filter through which oil is pumped, which comes directly from the fryer. The POF filters the entire oil flow, and has 7% – 10% less oil content compared to a conventional belt filter In this new fryer, the ‘POF’ is part of the trusted technology.

Read more about the POF by clicking here.

Kiremko OilGuard

The quality of fried potato products highly depends on the quality of the oil that is used. The Kiremko OilGuard measures total polar materials (TPM). The data collected allow constant monitoring of the oil quality. This inline measurements make sampling and lab testing redundant. This way the Oil Guard not only saves money in manpower, it also intensifies the sampling data.

Would you like to know more about our OilGuard? Contact us by clicking here.

What customers may expect

Customers change, markets change, products change, consumers change. Change is a constant driver for innovation at Kiremko. No wonder that the customer had a leading role in the development and design of the CORDA Invicta. No wonder that even the smallest functionality was reconsidered, rebuilt, retested. All the knowledge and experience of Kiremko is now shared with the market, by launching the CORDA Invicta.

Leaps ahead

The new fryer meets customer expectations, like Total Cost of Ownership, consistency of the end product and the highest safety standards. Together with an integrated controls system that uses the data out of the processing to improve the efficiency of the fryer. The steps we took resulted in a fryer that is leaps ahead of any other fryer. This fryer for the future is ready for launching customers, looking for state of the art frying technology, that puts them ahead as well.

The revolutionary design of the Kiremko CORDA Invicta Fryer is the result of years of intense research, development, testing, and consultation with our valued customers.

The frying oil pumped out of the fryer, is fed directly to the Primary Oil Filter and filtered. Adding the Primary Oil Filter to your process enables you to have a simplified circulation system with reduced oil volume.

EcoMiser is a green alternative to traditional methods of oil recovery after frying.

Bem Brasil experiences the value of partnership

In 2020, BEM Brasil already opened their fourth processing line with a nominal output capacity of 30 Metric tons per hour. With this, Bem Brasil proves that ambition, production and sustainability can be combined together.

Go to case