New Revolutionary Ecomiser Elite Oil Removal System

REYCO Systems, our well respected partner and leading manufacturer of oil removal systems, is thrilled to

announce the launch of their newest product, the EcoMiser® Elite Oil Removal System. The

EcoMiser® Elite model incorporates groundbreaking innovations to provide a much cleaner oil

removal system with minimal crumb build-up and vastly reduced potential for process fires.

- Keywords

- Reyco

- EcoMiser

- Innovations

- Oil removal

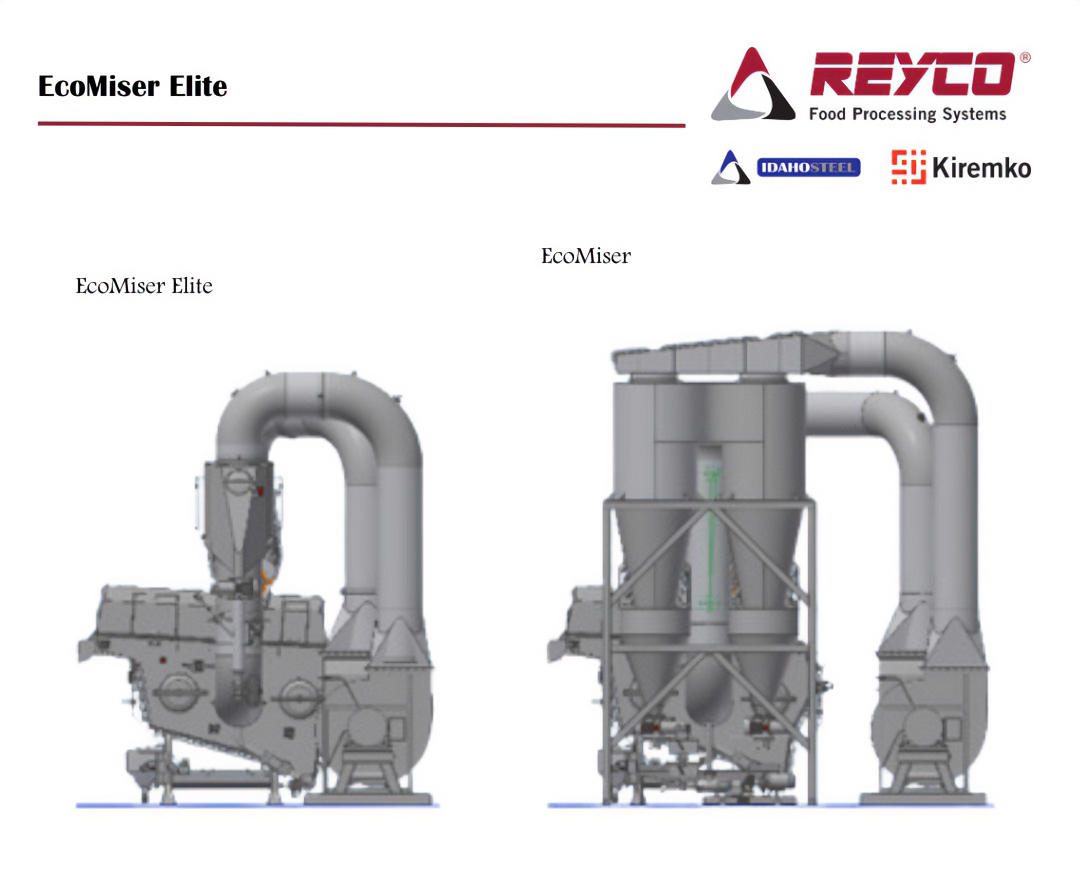

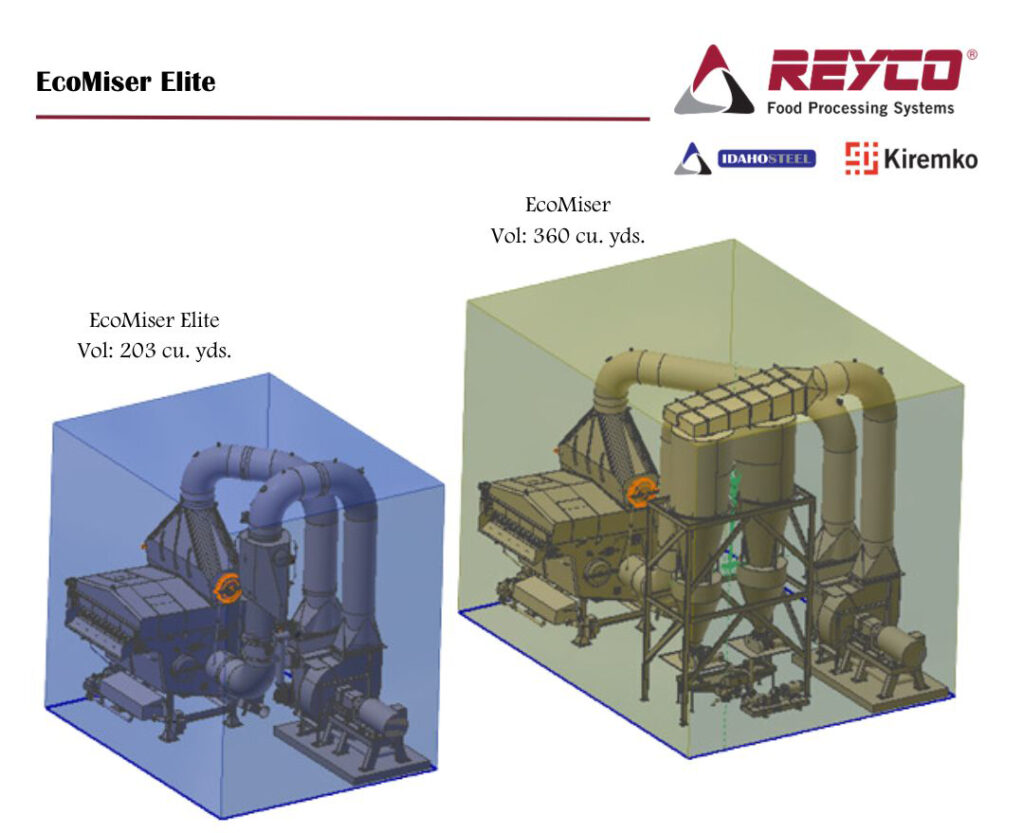

The EcoMiser® Elite system incorporates REYCO’s patented swirl tube technology, which completely removes the substantial cyclone requirements of previous misers and replaces them with revolutionary technology. This swirl tube design has proven to be as effective as the traditional cyclone design at a lower cost.

One of the significant advantages of the EcoMiser® Elite system is its smaller footprint. The new design reduces the overall floorspace requirements by up to 40%, making it possible to install the system in facilities previously thought too small to fit. Additionally, the swirl tube itself can be arranged in a nearly infinite array of installation configurations to give ultimate flexibility to engineering and production teams.

Smaller foodprint

One of the significant advantages of the EcoMiser® Elite system is its smaller footprint. The new design reduces the overall floorspace requirements by up to 40%, making it possible to install the system in facilities previously thought too small to fit. Additionally, the swirl tube itself can be arranged in a nearly infinite array of installation configurations to give ultimate flexibility to engineering and production teams.

The internal hot oil rinse system has been completely reengineered using computerized fluid design (CFD) modeling. The new design incorporates a dedicated pump and skid optimized to provide the correct oil pressure and flow at each rinse nozzle to thoroughly clean the suction plenum, drain pans, swirl tube separation chamber, and other areas.

The new design incorporates several evolutionary developments, and shows our continued dedication to helping our customers improve.

REYCO has also listened to customer feedback and redesigned the size, shape, and placement of cleaning doors to allow for greater access. These doors now

include shut-off switches as a standard to improve safety during operation.

“We are thrilled to introduce the EcoMiser® Elite Oil Removal System,” said Brian Cardwell, REYCO Systems® Director of Engineering. “The new design incorporates several evolutionary developments, and shows our continued dedication to helping our customers improve.”

For more information about the EcoMiser® Elite Oil Removal System, please visit REYCO systems or contact Brian Scott at bscott@reycosys.com.