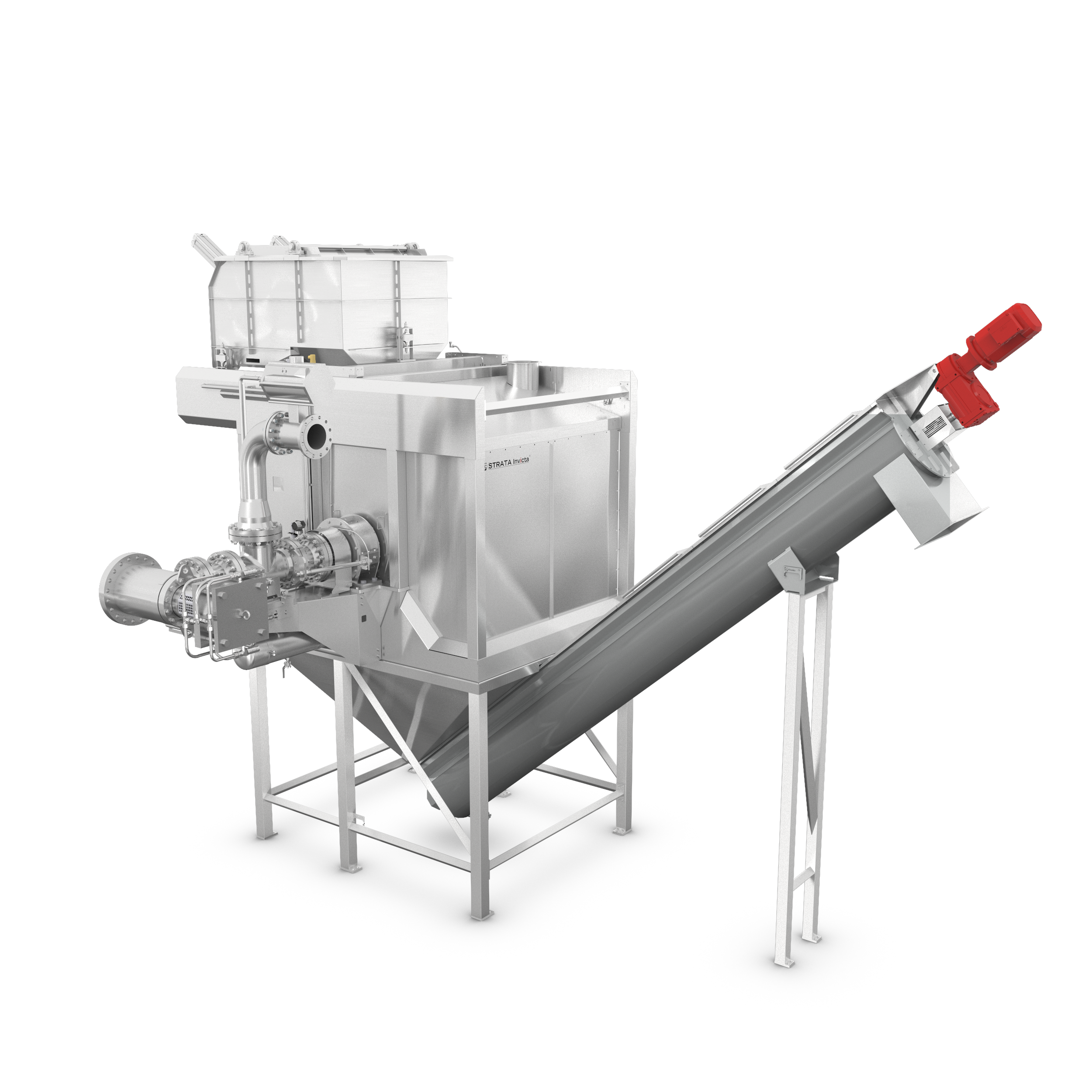

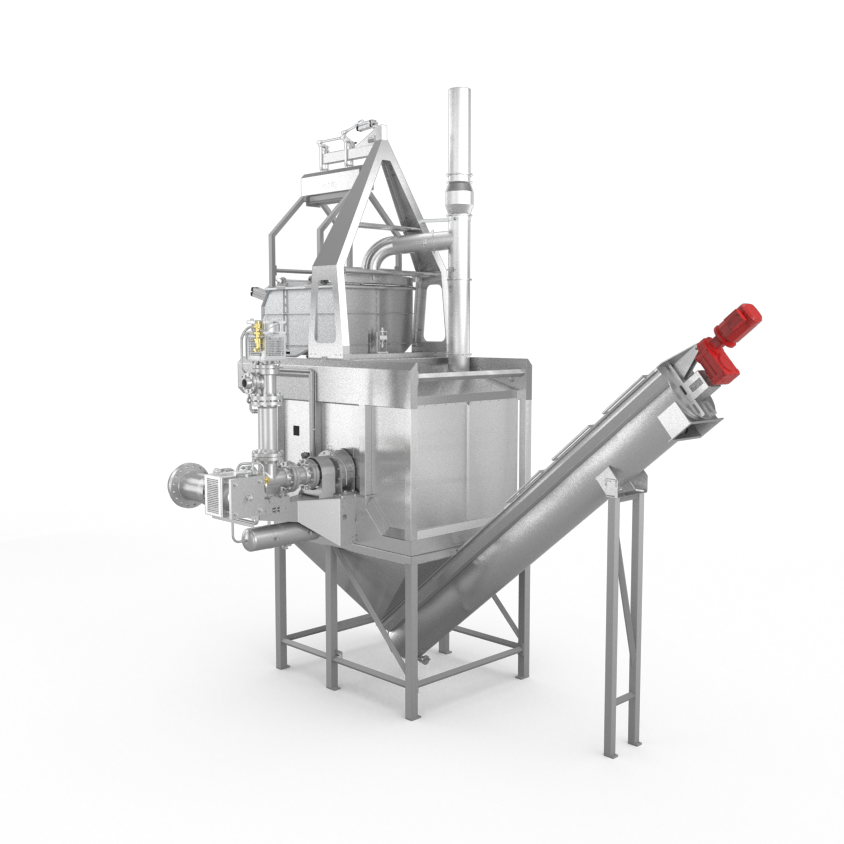

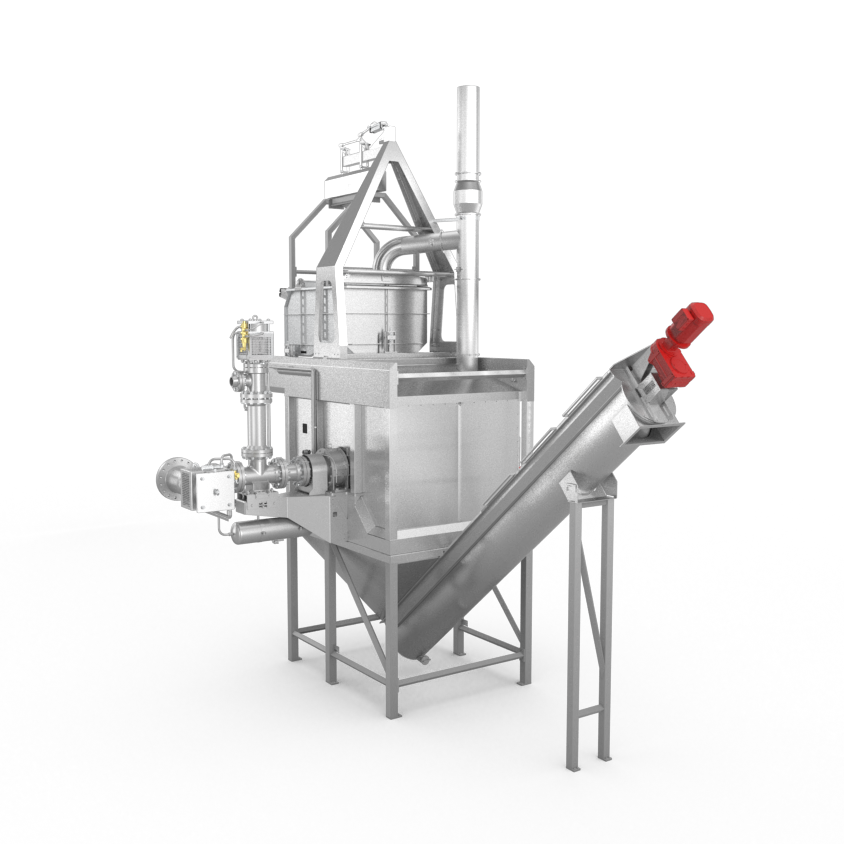

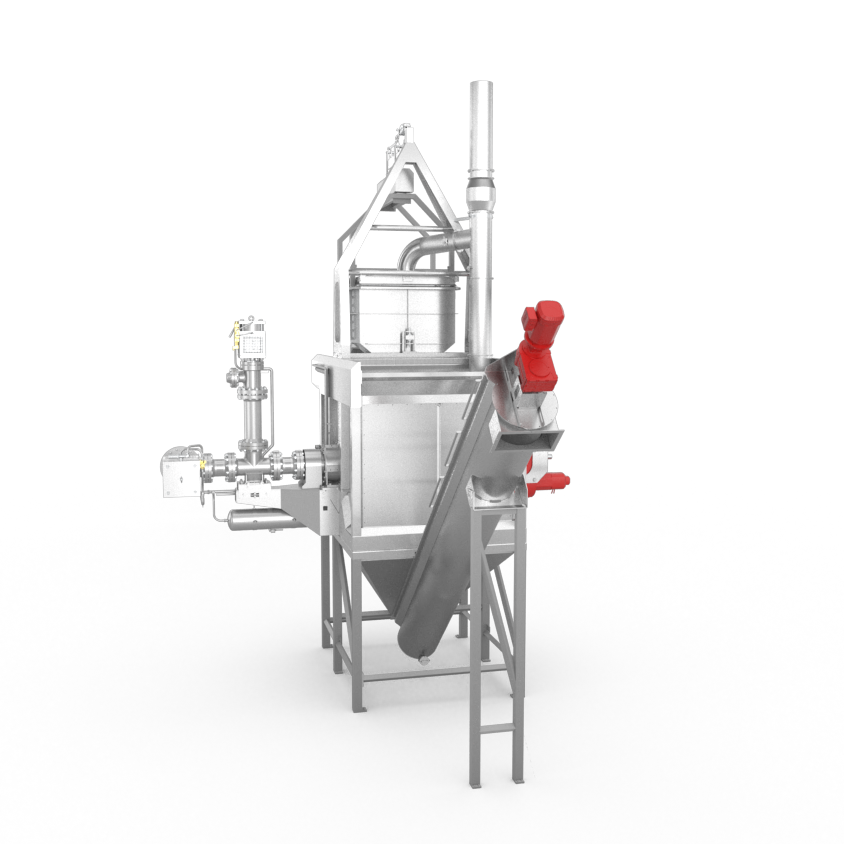

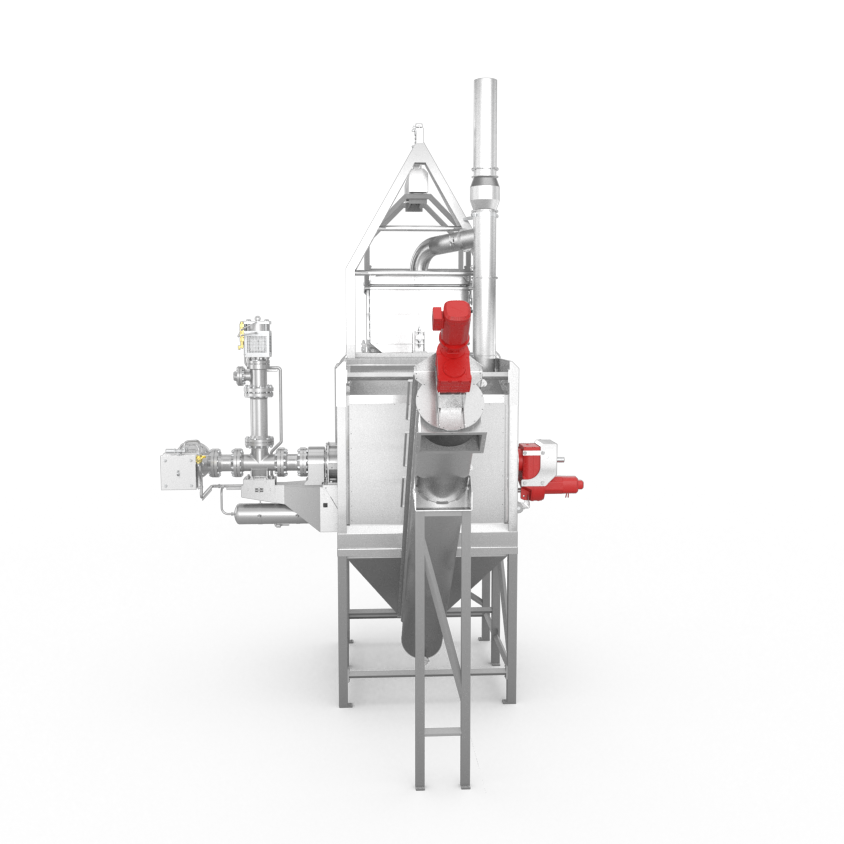

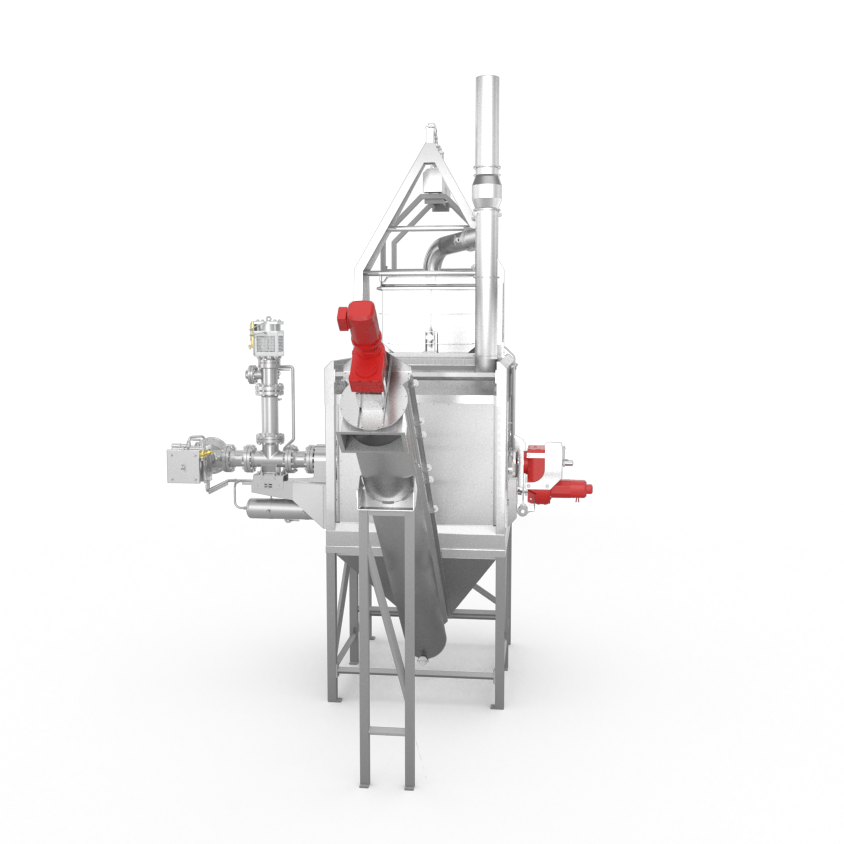

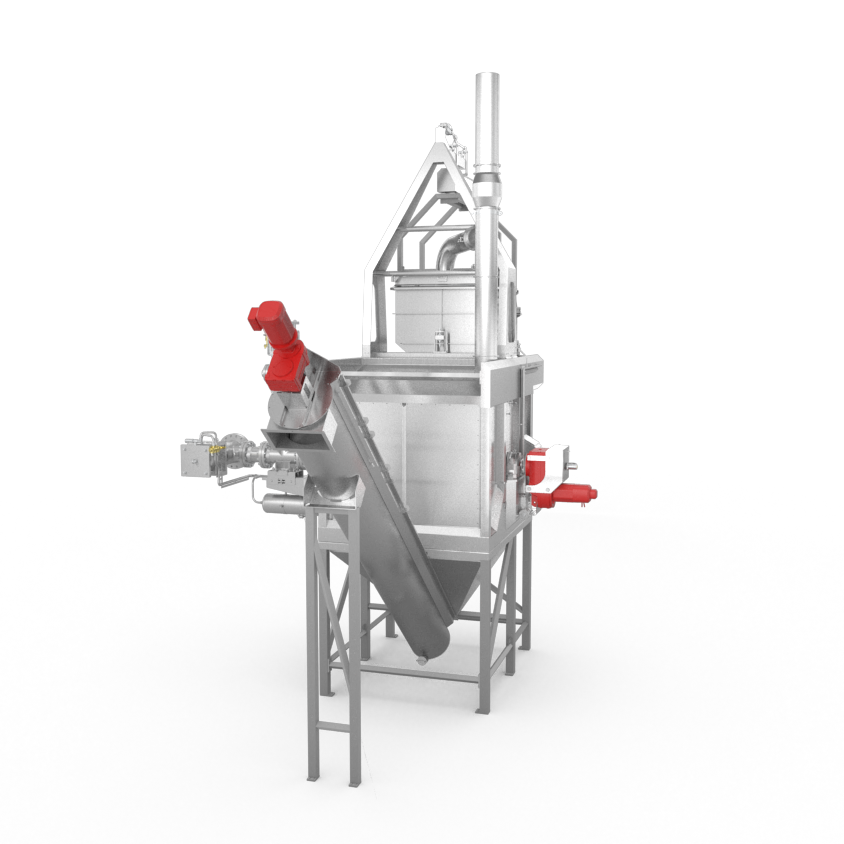

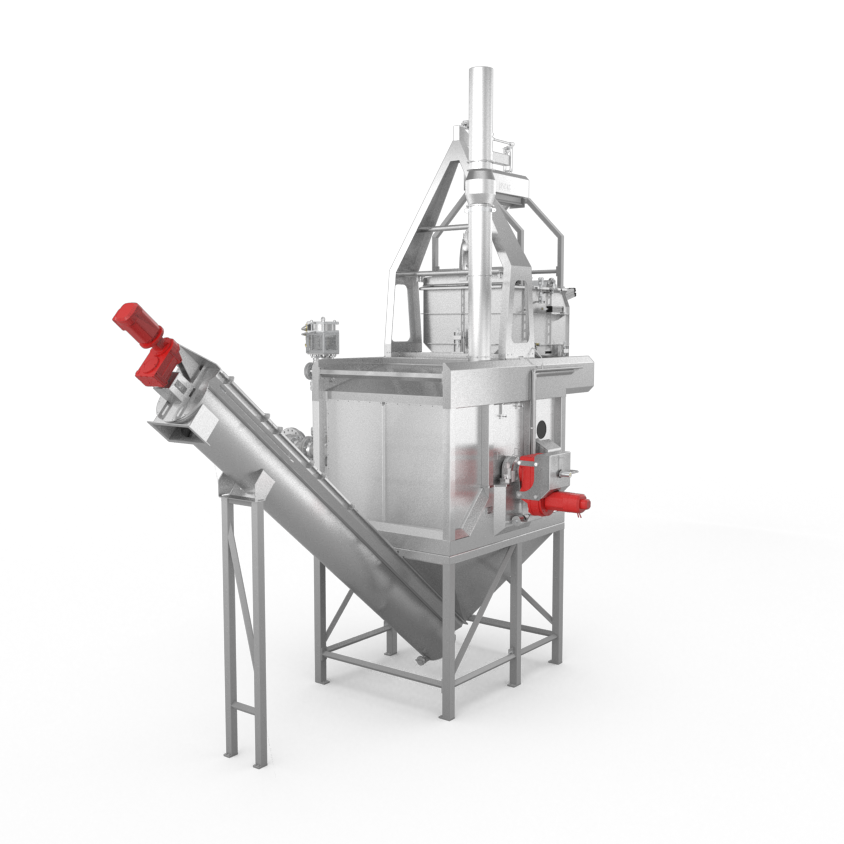

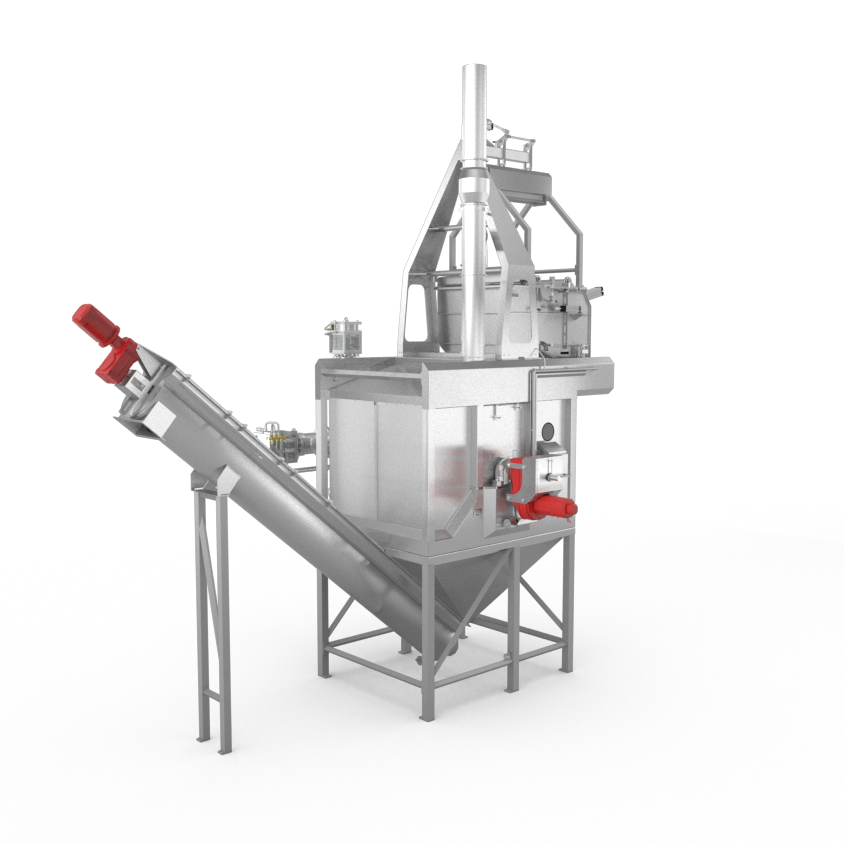

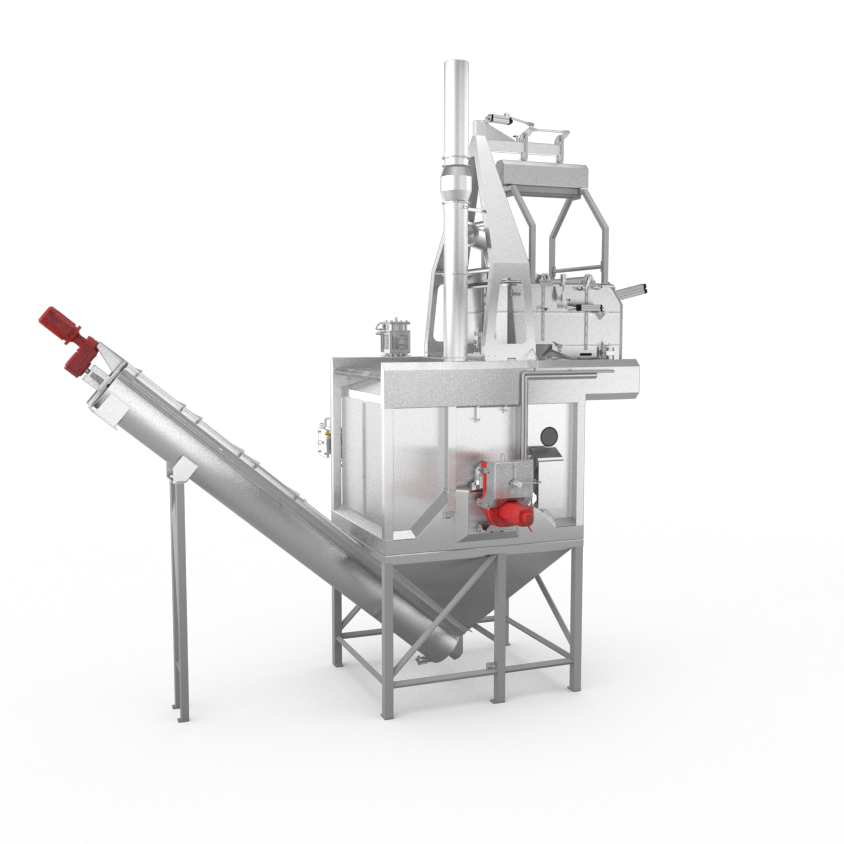

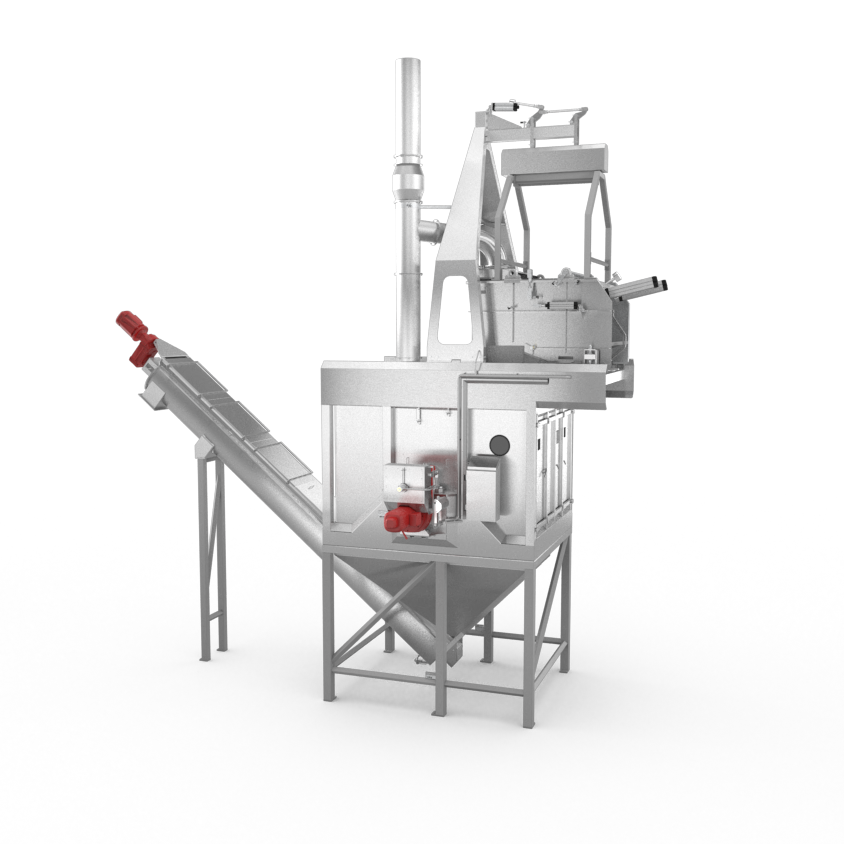

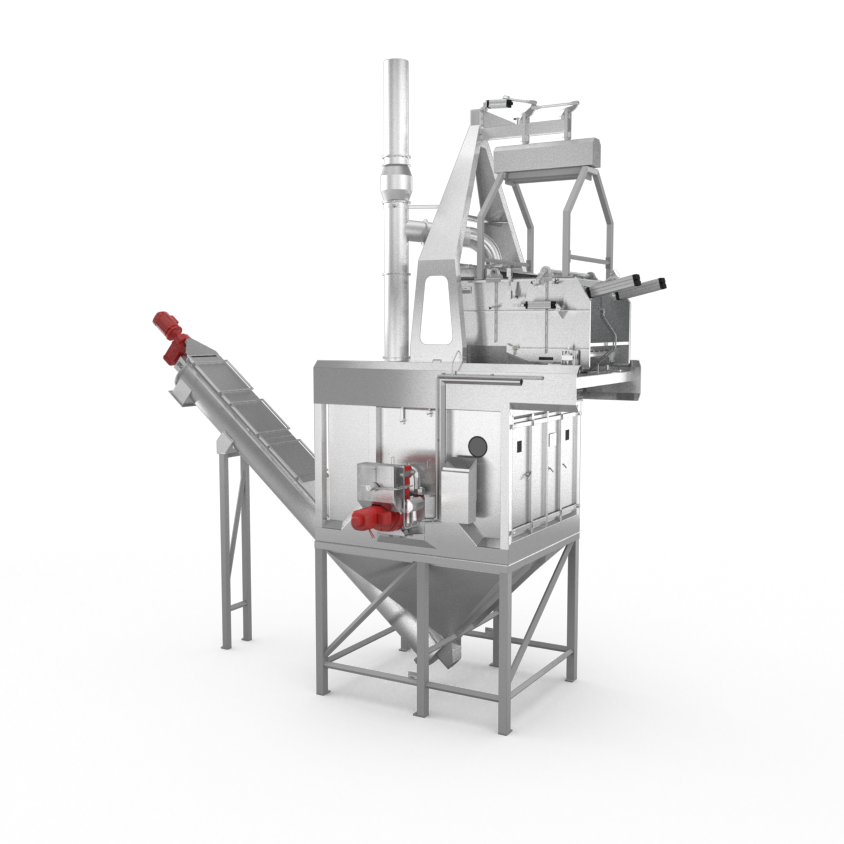

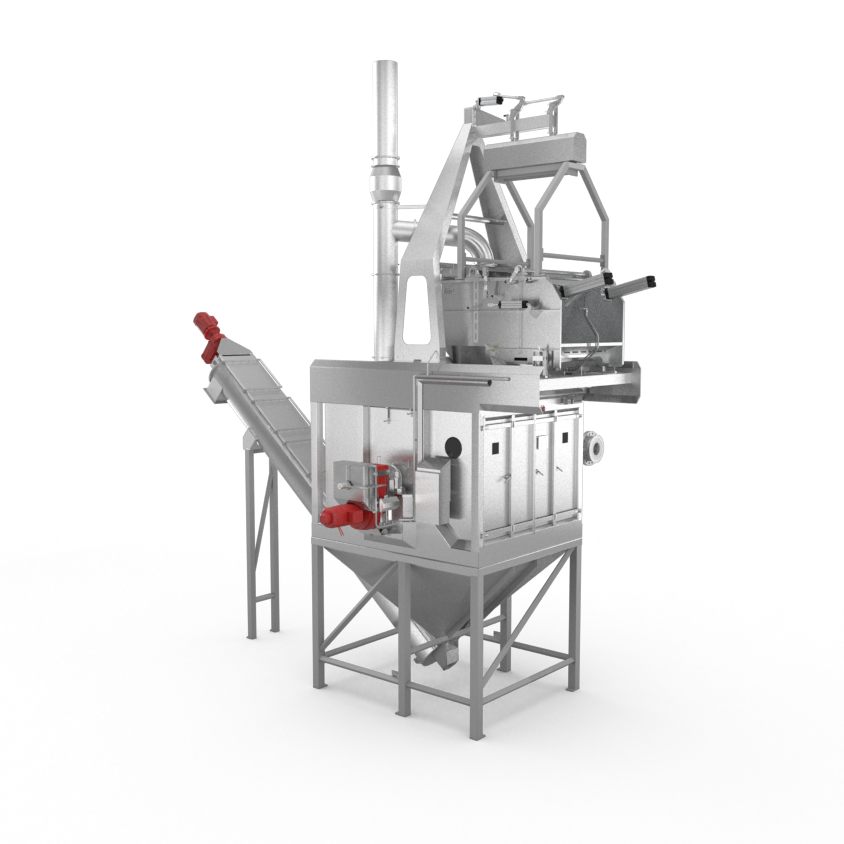

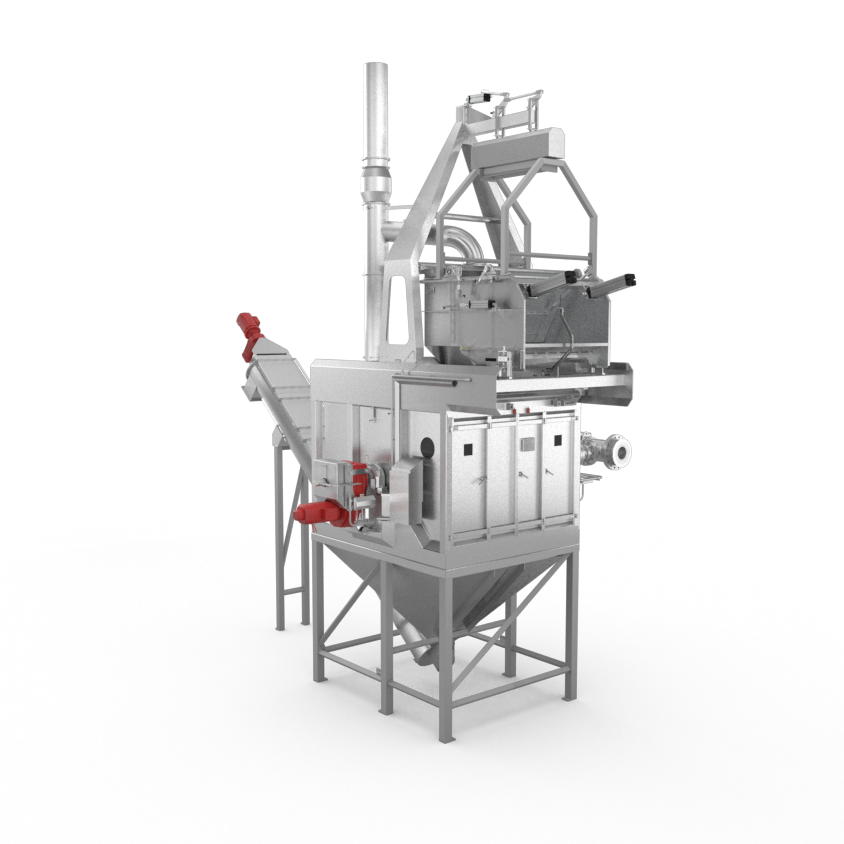

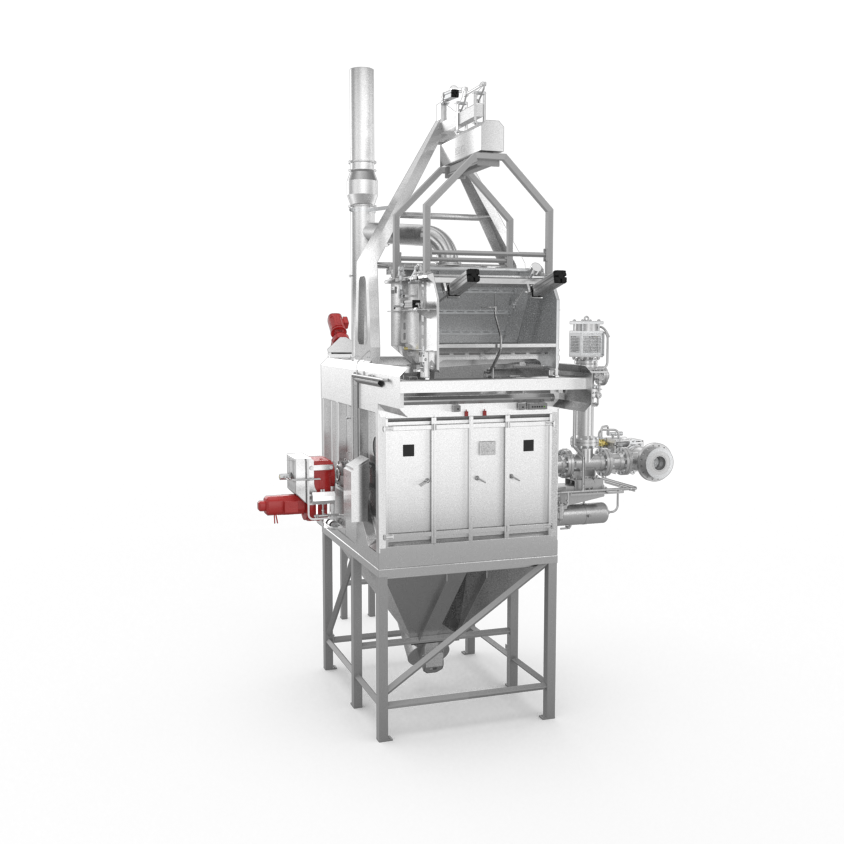

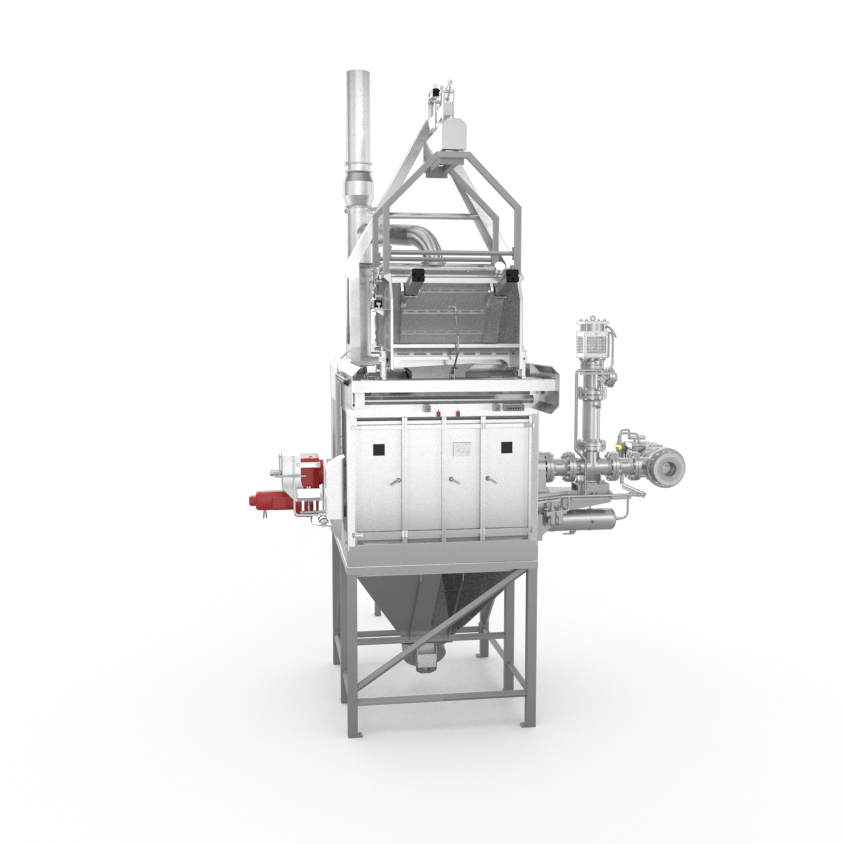

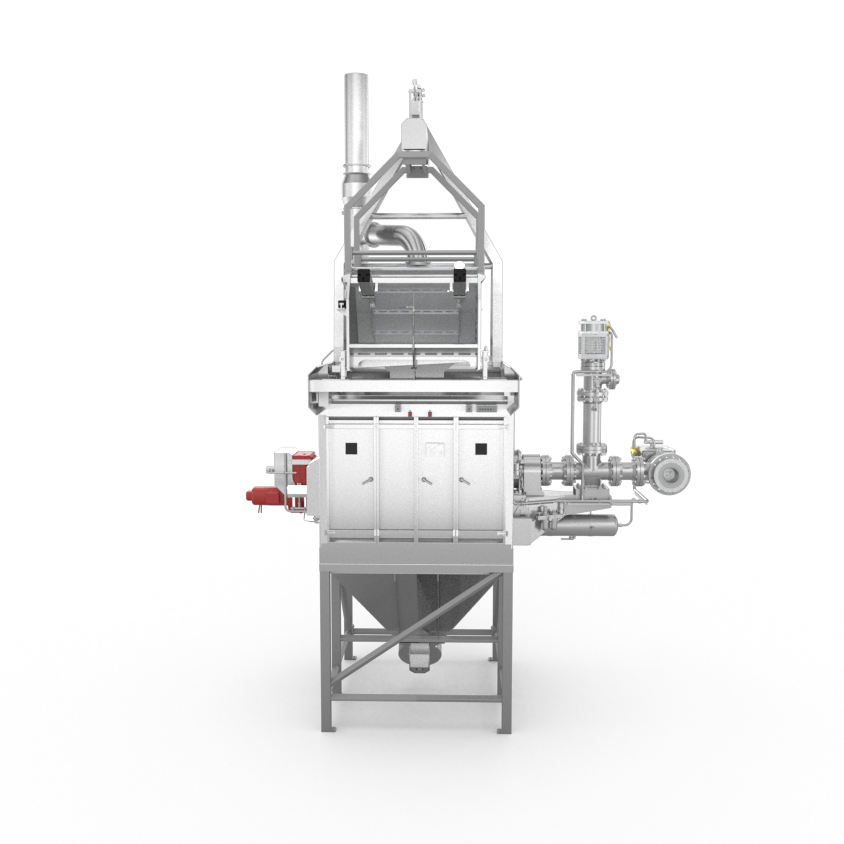

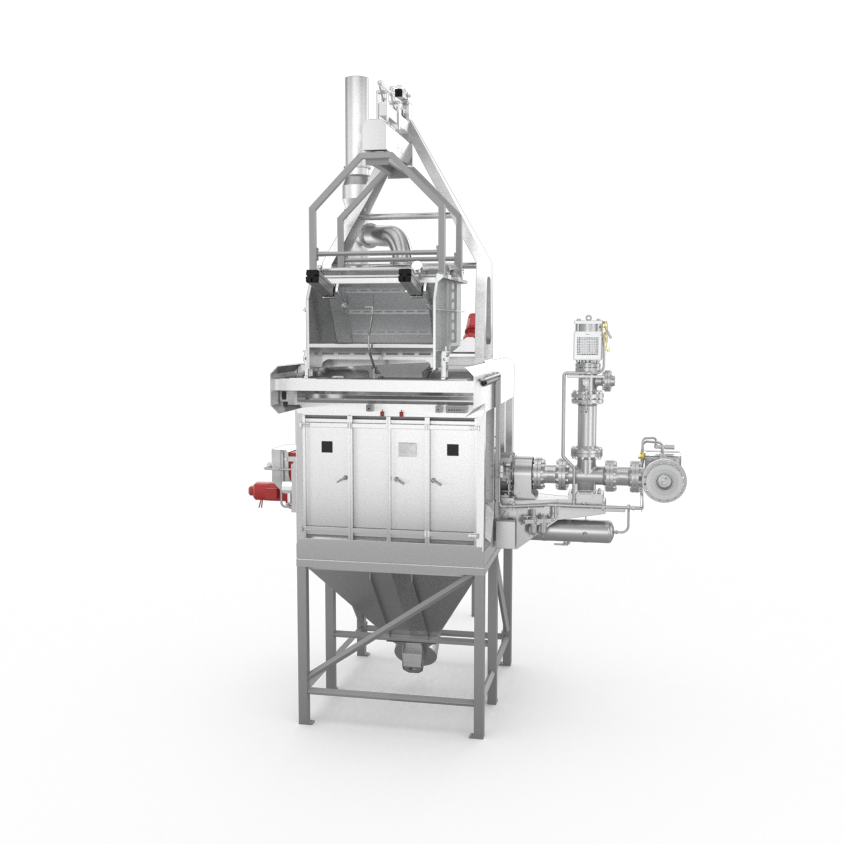

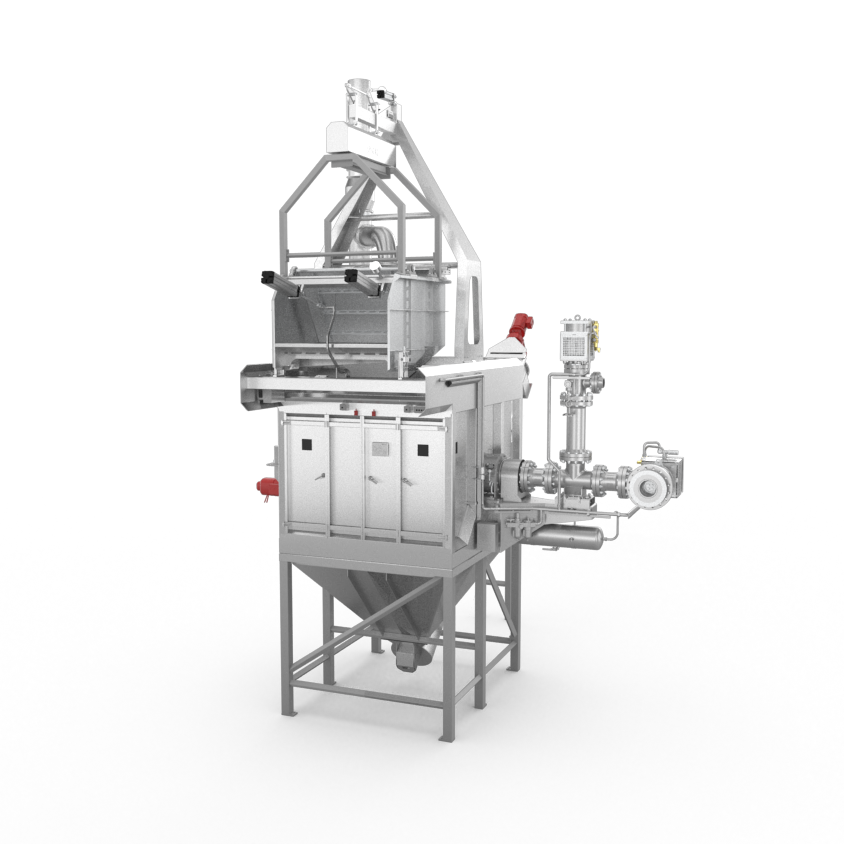

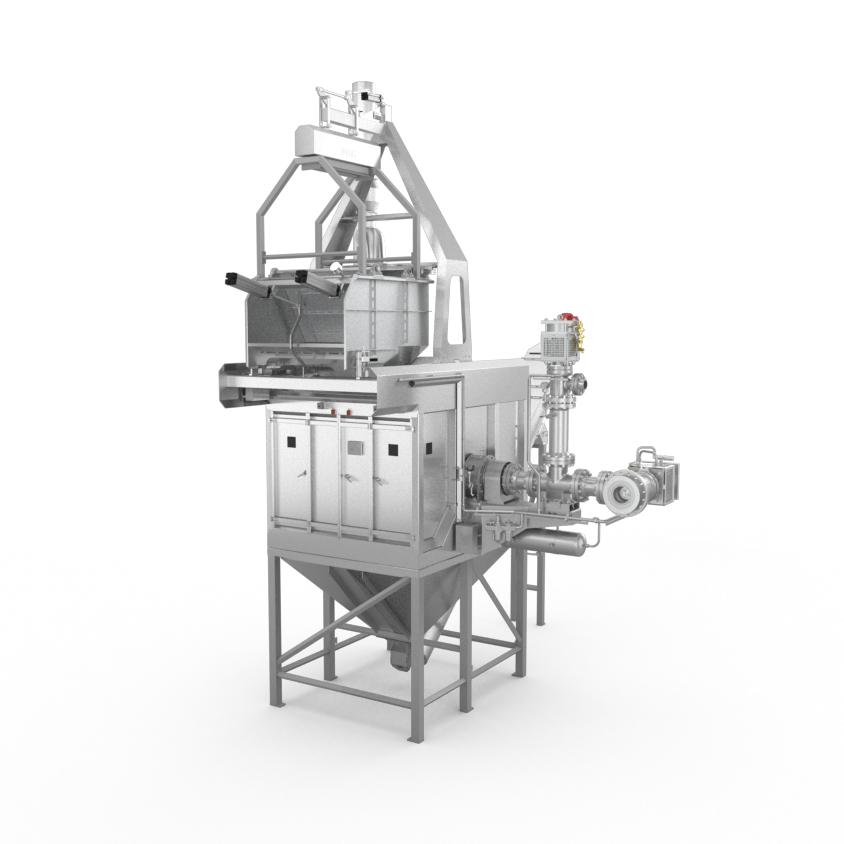

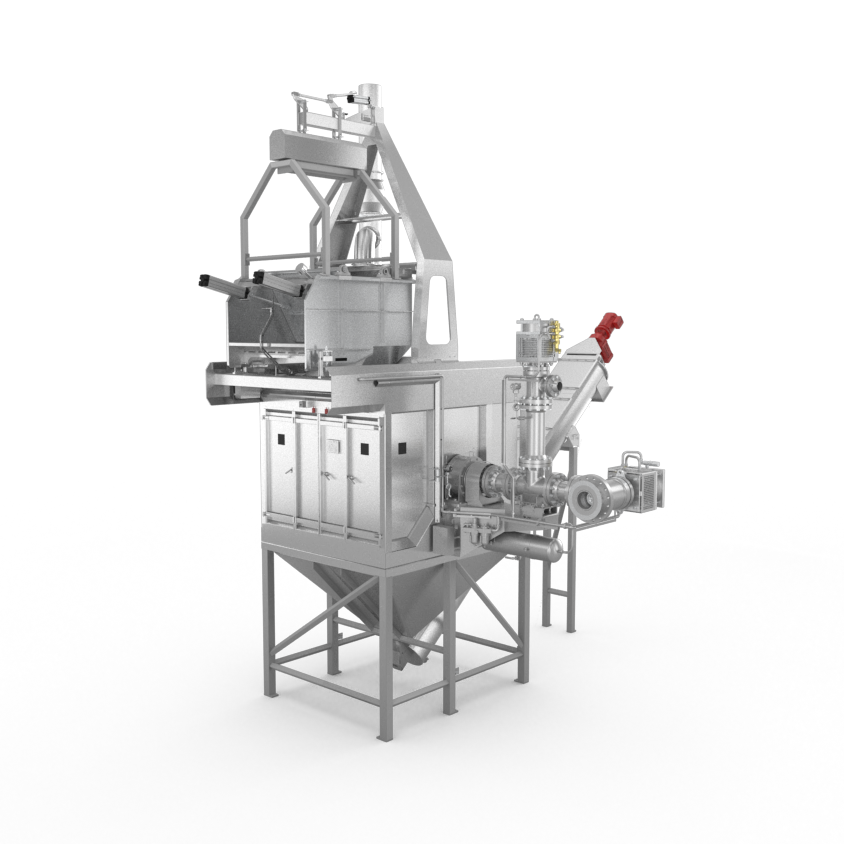

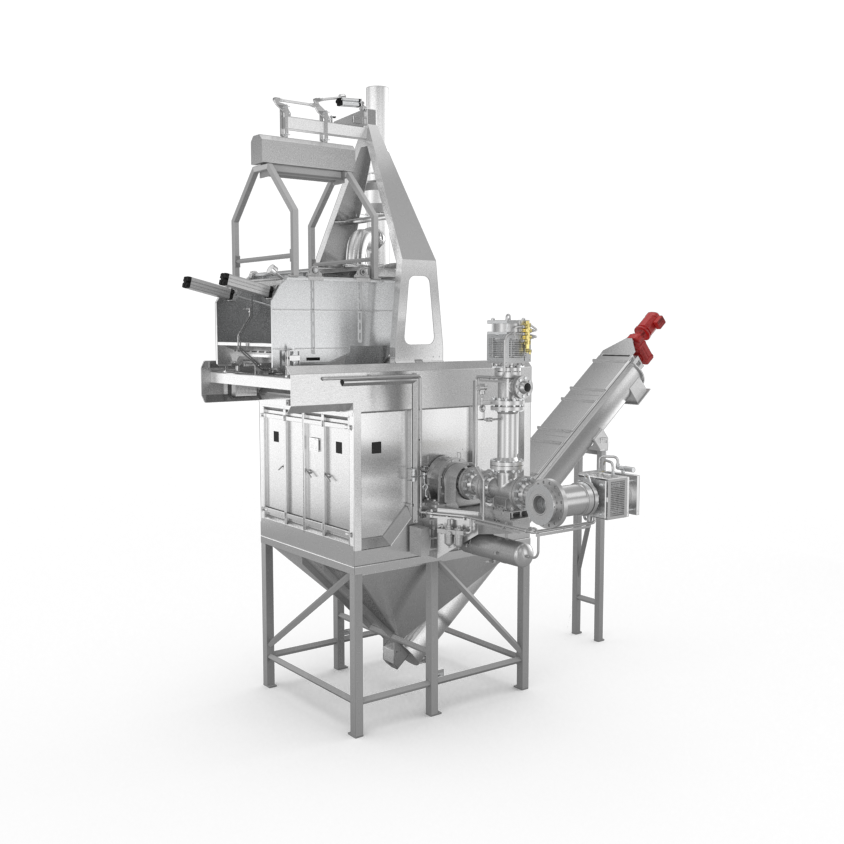

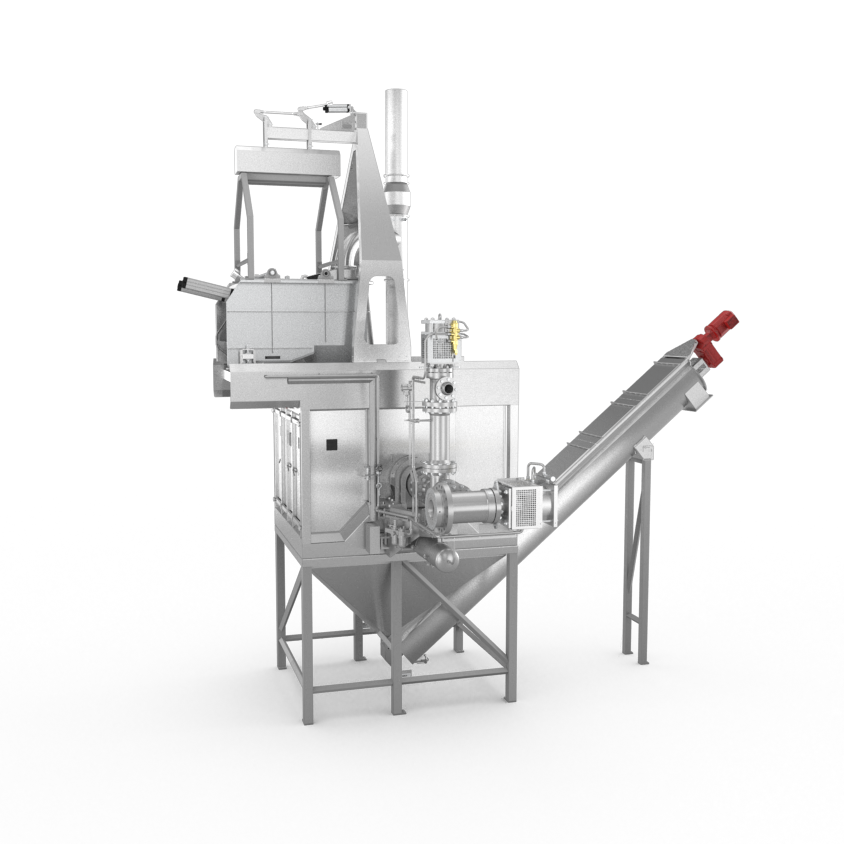

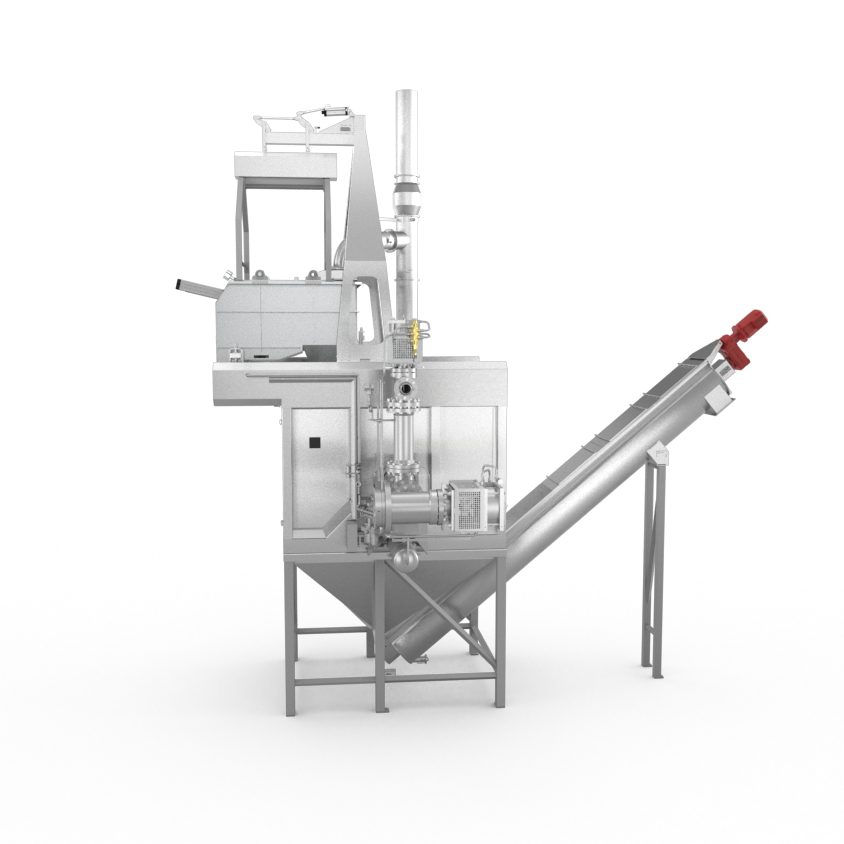

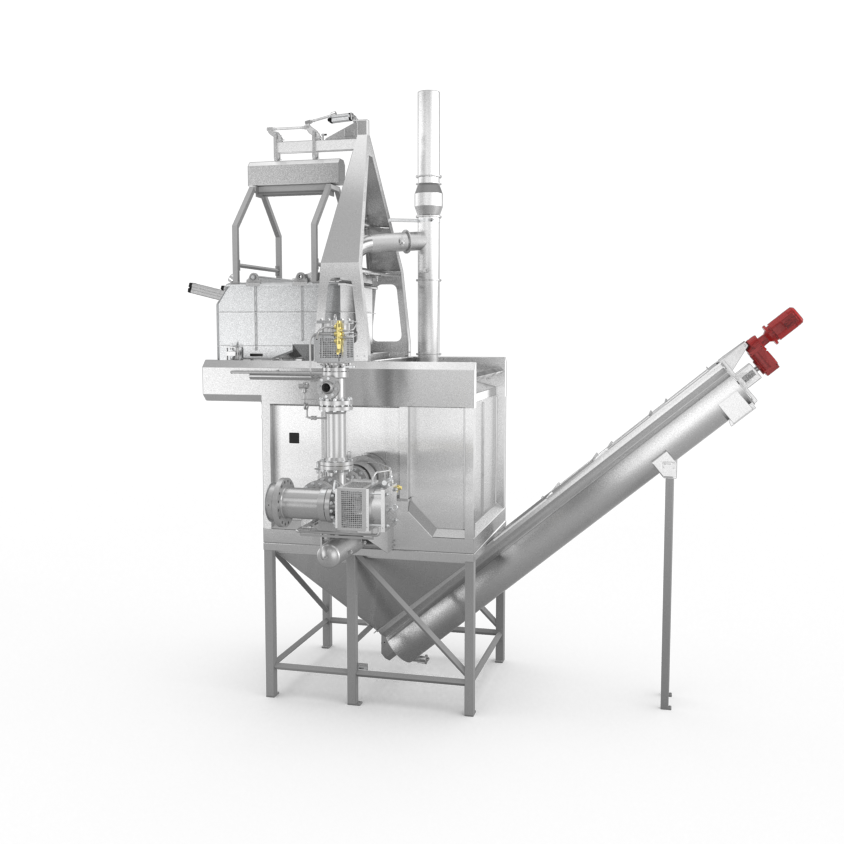

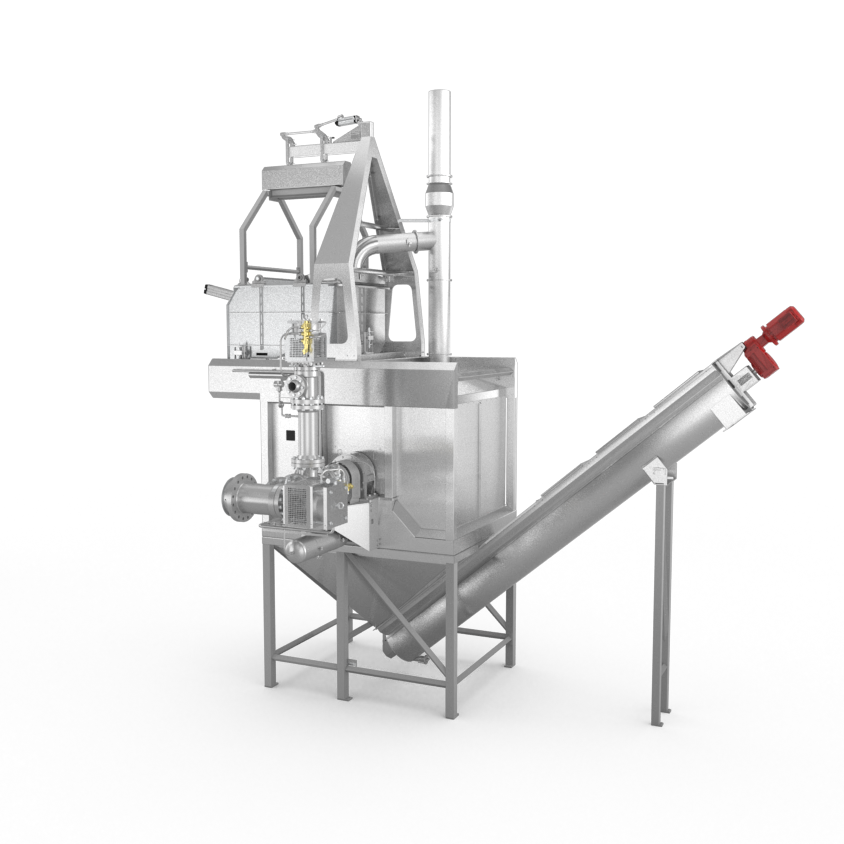

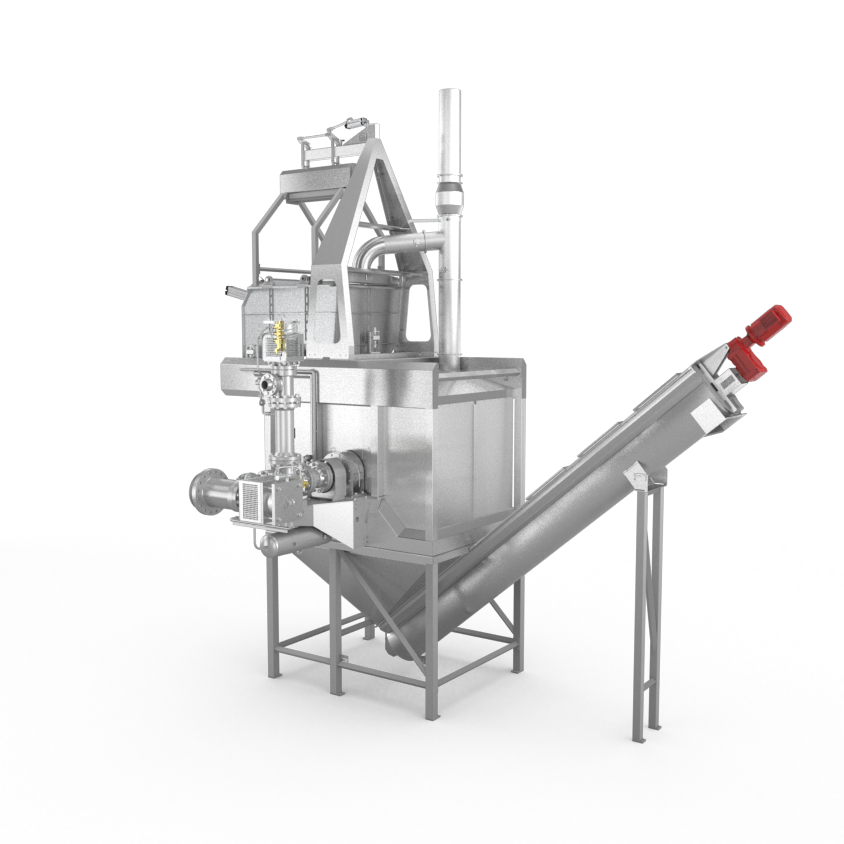

STRATA Invicta

Peeling

By offering maximum yields at the shortest cycle time, STRATA Invicta sets a new standard in steam peeling systems.

Video

Learn more about the Strata Invicta

Download brochure

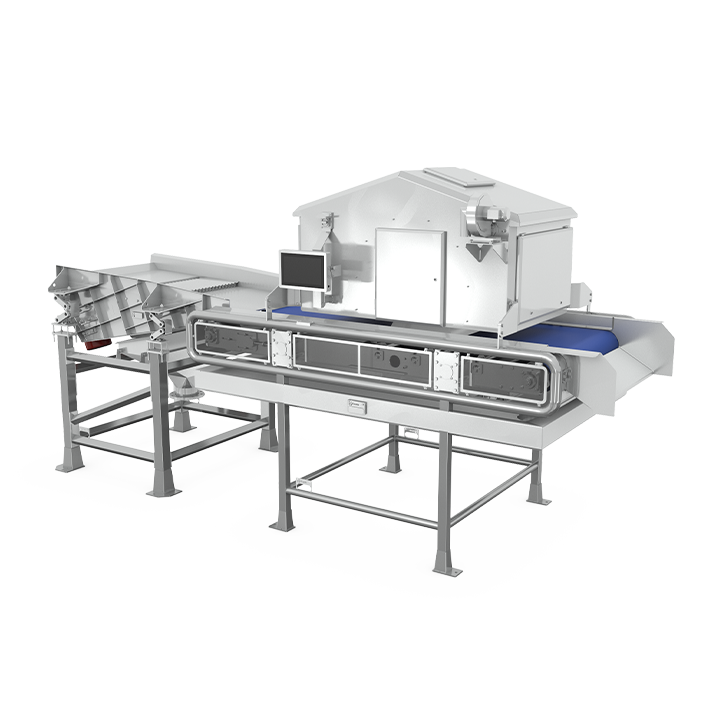

Dry brush machines are used to remove the potato peel after steam peeling.

PeelGuard is an optical measuring and weighing instrument that detects residual peels and the presence of dark, green or black spots.

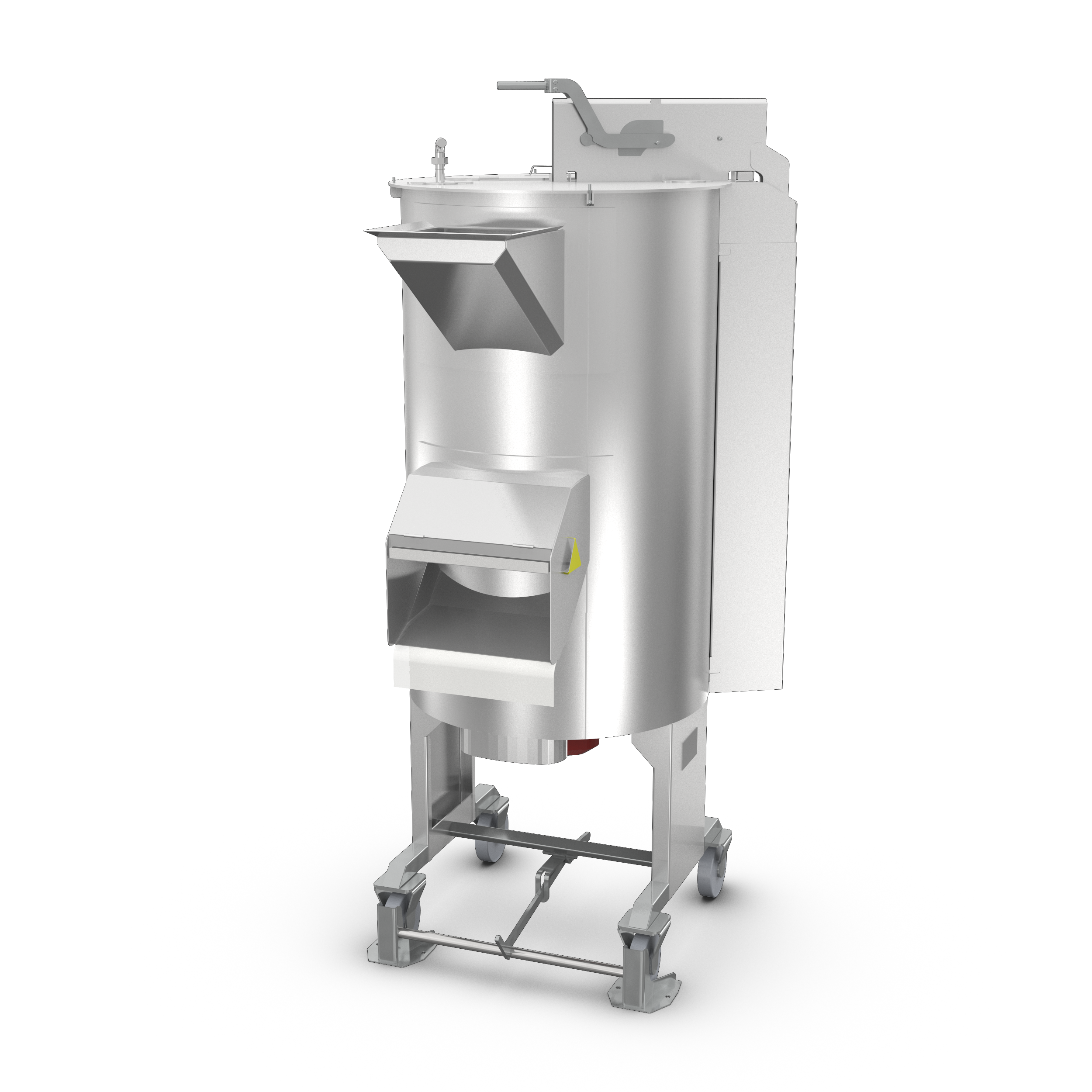

Simple, efficient and slim, the abrasive peeler guarantees smooth, clean results every time.

30 STRATA Invicta's

in 30 months

“We didn’t know of this anniversary of the Kiremko STRATA Invicta® steam peeler at the moment we bought it”, Aviko Belgium Project Manager Cor Koole admits. “We just bought it because it offers us the highest reliability. We know the Kiremko STRATA Invicta® from other Aviko locations.

Go to case